Rosewool Insulation Refractory Co.,Ltd.

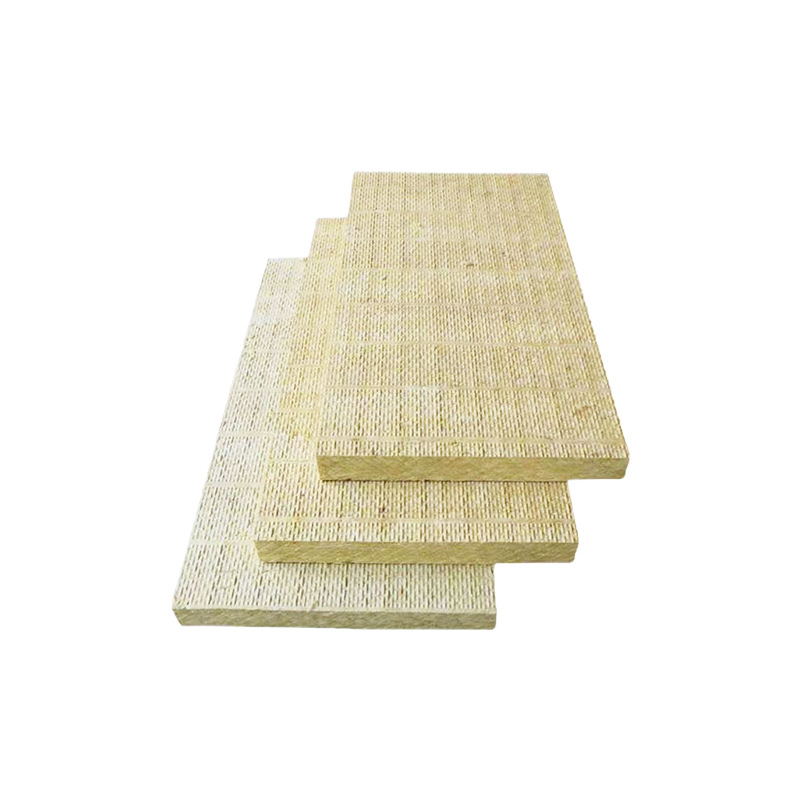

| Density | Kg/m3 | 100 |

| Thermal Conductivity | W/(m▪K) | ≤0.038 |

| Hydrophobic Rate | % | ≥98 |

| Acid Coefficient | % | ≥1.8 |

| Moisture Absorption Rate | % | ≤1 |

| Water absorption(partial immersion) | Kg/m2 | Short time(24h): ≤0.5 |

| long time(28h): ≤2.0 | ||

| Combustion Performance | Class A1 Non-combustion | |

| Size | mm | 1200*600*75/100mm |

.jpg)