In high-temperature industrial environments like steel manufacturing, thermal insulation isn’t just a luxury—it’s a necessity. For facilities operating furnaces at extreme temperatures (often exceeding 1000°C), maintaining efficiency, extending equipment lifespan, and ensuring worker safety are top priorities. Enter 50mm calcium silicate board (CSB): a versatile, high-performance insulation material that’s proving its mettle in some of the toughest industrial settings. Let’s dive into a real-world case study where 50mm calcium silicate board transformed a steel plant’s furnace insulation system.

The client: A leading steel manufacturing plant in Gujarat, India, specializing in rebar production.

The problem: The plant’s re-heating furnaces, critical for processing raw steel, faced two major issues:

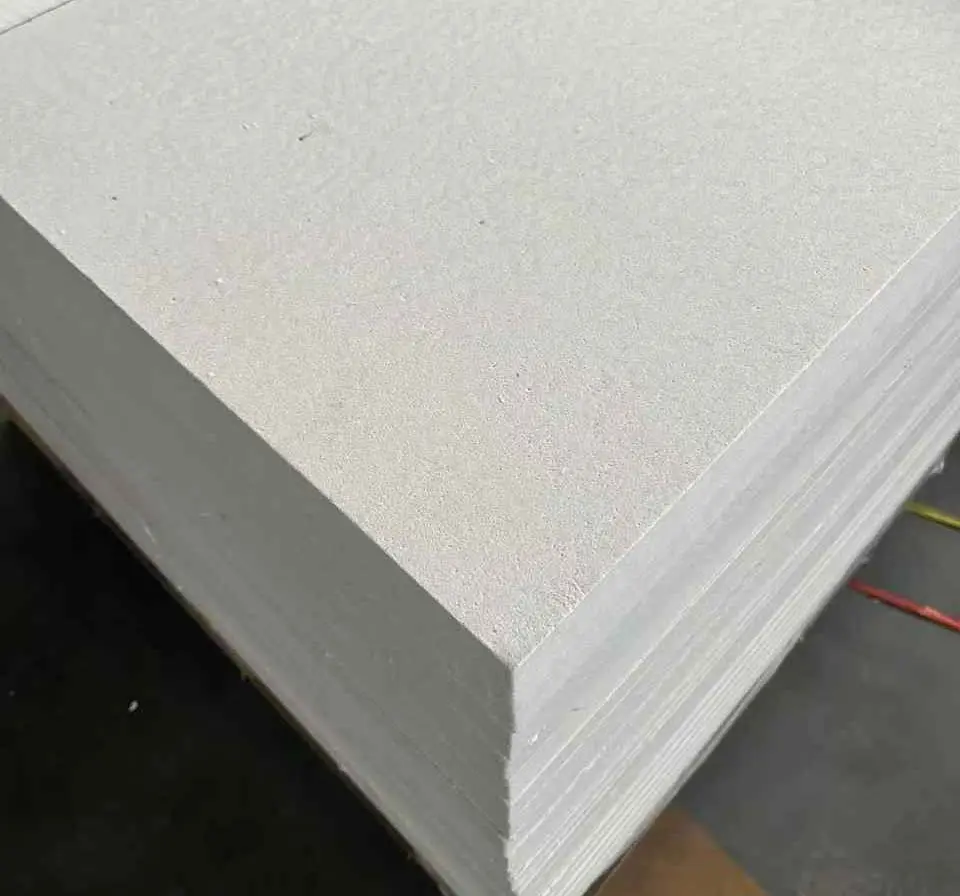

To address these challenges, the plant turned to 50mm calcium silicate board—a non-metallic, inorganic insulation material engineered for extreme heat resistance. Here’s how it was deployed:

The furnaces’ curved inner walls required insulation that could adapt seamlessly. The 50mm calcium silicate board panels were custom-cut and precision-machined with grooves to match the furnace’s radius, ensuring a snug fit without gaps. This eliminated weak points where heat could escape.

The CSB boards were installed behind the existing refractory lining as a secondary insulation layer. This “backup” system worked in tandem with the primary refractory:

The implementation of 50mm calcium silicate board delivered transformative results for the Gujarat steel plant:

By adding the CSB layer, the furnaces’ thermal efficiency improved dramatically. Heat that once escaped through the outer shell was now retained, cutting energy consumption by 20%. For a facility operating 24/7, this translated to annual savings of over $150,000 in fuel costs alone.

The refractory lining, no longer subjected to rapid temperature fluctuations (thanks to the CSB’s heat-buffering effect), degraded much slower. Post-installation inspections revealed a 30% increase in refractory lifespan—from 12 months to 16 months—reducing maintenance downtime and replacement costs.

The outer surface temperature of the furnaces dropped by 35% (from 85°C to 55°C), eliminating burn hazards for workers during routine checks or repairs. This boosted safety compliance and reduced the need for specialized protective gear.

So why did the Gujarat plant select 50mm CSB over other insulation materials? Here are the key factors:

CSB is rated for continuous use up to 1000°C (some grades even withstand 1200°C), making it ideal for steel furnaces. Unlike organic insulators (e.g., foam) or lower-performance ceramics, CSB retains structural integrity under prolonged high heat.

With a thermal conductivity of just 0.058 W/m·K (at 600°C), 50mm CSB efficiently slows heat transfer. This “thermal barrier” minimizes energy loss while keeping the furnace shell cool enough for safe operation.

Steel furnaces are exposed to moisture (from steam or cooling processes), chemical vapors, and thermal shock. CSB is inherently water-resistant (when properly sealed), resistant to alkali and acid attack, and can withstand rapid temperature changes without cracking—critical for long-term performance.

The 50mm thickness struck a balance between insulation performance and practicality. The boards were lightweight yet rigid, allowing easy cutting and fitting around the furnace’s complex curves. This reduced installation time by 25% compared to bulkier insulation materials.

For the Gujarat steel plant, 50mm calcium silicate board wasn’t just an insulation upgrade—it was a strategic investment in efficiency, safety, and cost savings.