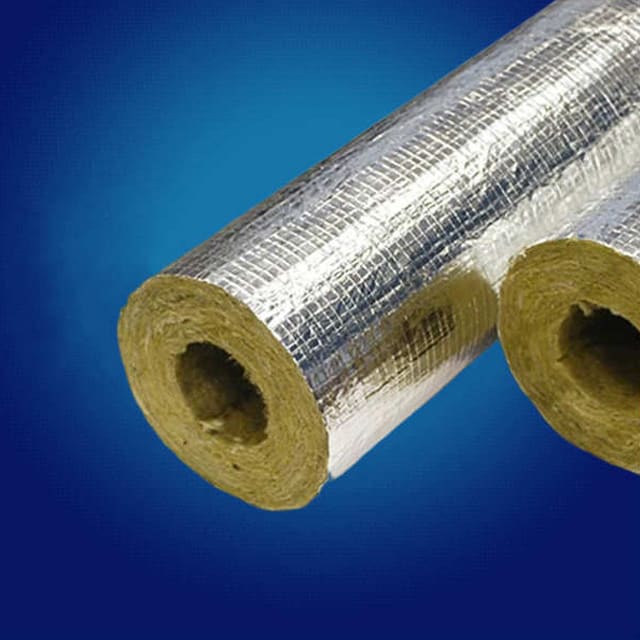

In the dynamic world of international trade, the delivery status of products is of utmost importance, especially when it comes to essential building materials like

rock wool roll insulation. For our valued customers in the Philippines, we understand that timely and reliable delivery is crucial for the smooth progress of construction and industrial projects. Here, we provide a comprehensive update on the delivery status of our rock wool roll insulation products to the Philippines.

Production Preparation: Ensuring Quality and Quantity

Before any delivery, our production team initiates a meticulous process to meet the specific requirements of Philippine customers. We adhere to international quality standards, such as ISO 9001 and relevant ASTM and EN norms, ensuring that each roll of rock wool insulation boasts excellent thermal insulation, fire resistance, and sound absorption properties.

To guarantee sufficient supply, we closely monitor inventory levels and ramp up production when large orders from the Philippines are confirmed. Our state - of - the - art manufacturing facilities are equipped to handle bulk production efficiently, reducing lead times without compromising on quality. This preparation phase is a cornerstone in ensuring that the rock wool roll insulation reaches customers in perfect condition and within the promised timeframe.

Logistics and Transportation: Navigating the Journey

Once production is complete, the rock wool roll insulation is ready for its journey to the Philippines. We collaborate with trusted international logistics partners with extensive experience in shipping to Southeast Asia. Our transportation options include sea freight, which is the most cost - effective and commonly used method for large - scale deliveries.

Shipping containers are carefully loaded to protect the rock wool rolls from damage during transit. We also ensure that all necessary documentation, such as bills of lading, commercial invoices, and certificates of origin, is in order. This paperwork is essential for smooth customs clearance in the Philippines, minimizing potential delays. Additionally, we utilize advanced tracking systems, allowing our Philippine customers to monitor the real - time location of their shipments from the moment they leave our factory until they reach the destination port.

Delivery Assurance: A Customer - Centric Approach

Our commitment to customers doesn't end with shipping. We maintain open lines of communication throughout the delivery process. Our dedicated customer service team in the Philippines and at our headquarters is always available to answer any queries regarding the delivery status of

rock wool roll insulation. Whether it's an update on the expected arrival time or clarification on customs procedures, we strive to provide prompt and accurate information.

In case of unforeseen circumstances, such as adverse weather conditions affecting shipping schedules or unexpected customs inspections, we have contingency plans in place. We work closely with our logistics partners to find solutions quickly, ensuring that any disruptions are minimized. Our goal is to make the delivery process as seamless as possible for our Philippine customers, enabling them to start using our high - quality rock wool roll insulation in their projects without unnecessary delays.