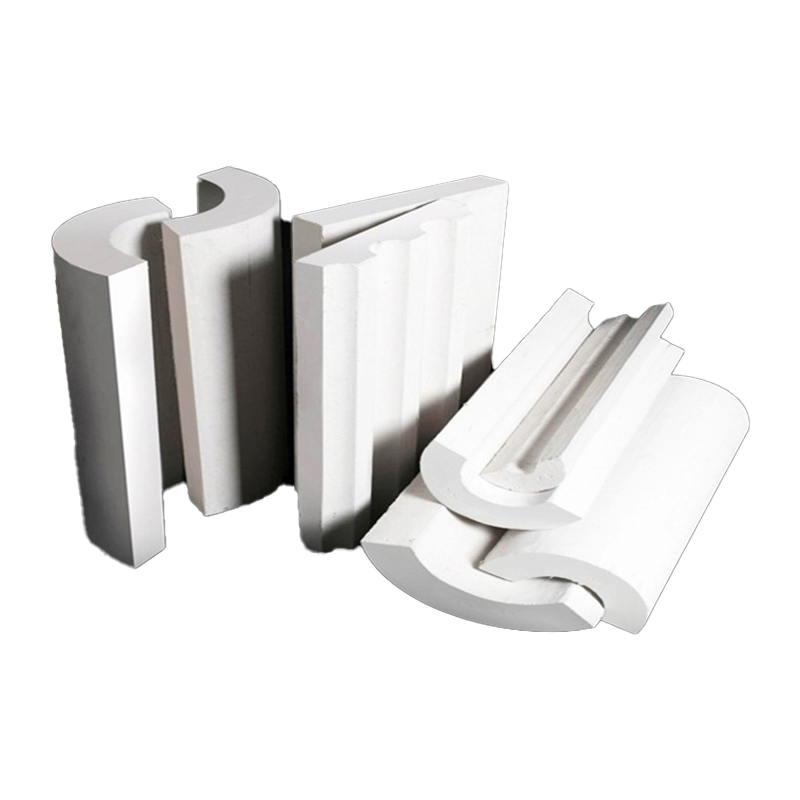

In the fields of industrial production and construction, pipeline insulation is crucial, not only related to the effective utilization of energy, but also affecting the stable operation of the entire system. Rosewool Insulation Refractory Co.,Ltd, as a leading player in the industry, produces high-density calcium silicate pipeline insulation materials that rank among the top in the market and are highly trusted by customers.

Rosetexwool's high-density calcium silicate pipeline insulation material has many significant advantages, making it stand out among many similar products. From the perspective of insulation performance, its thermal conductivity is extremely low, which can effectively prevent heat transfer and greatly reduce energy loss. Whether in high-temperature industrial pipelines or building heating pipeline systems with strict temperature control requirements, it can stably exert its excellent insulation efficiency, ensure that the temperature of the medium inside the pipeline is maintained in an ideal state, reduce energy consumption costs, and improve the energy utilization efficiency of the system.

High Denstiy Calcium Silicate

| Item |

Unit |

Index |

| Bulk Density |

Kg/m3 |

≥ 800kg/m3 |

| Max. Temperature |

℃ |

1000-1100 |

| Rupture Strength |

Mpa |

≥6.5 |

| Compressive Strength |

Mpa |

≥ 12 |

| Linear Shrinkage |

% |

≤ 1 |

Thermal Conductivity

(W/m.k) |

100℃ |

0.113 |

| 200℃ |

0.120 |

| 300℃ |

0.121 |

| 400℃ |

0.125High Denstiy Calcium Silicate

| Item |

Unit |

Index |

| Bulk Density |

Kg/m3 |

≥ 800kg/m3 |

| Max. Temperature |

℃ |

1000-1100 |

| Rupture Strength |

Mpa |

≥6.5 |

| Compressive Strength |

Mpa |

≥ 12 |

| Linear Shrinkage |

% |

≤ 1 |

Thermal Conductivity

(W/m.k) |

100℃ |

0.113 |

| 200℃ |

0.120 |

| 300℃ |

0.121 |

| 400℃ |

0.125 |

|

In terms of strength, this material exhibits excellent performance. Its high-density characteristics endow it with high compressive and flexural strength. In practical use, even in complex installation environments, as well as minor collisions, compressions, and other situations in daily use, it is not prone to cracking, deformation, and other problems, ensuring the integrity and stability of the insulation layer, greatly reducing the frequency of later maintenance and replacement, and lowering maintenance costs.

-%E6%8B%B7%E8%B4%9D.jpg)

In addition, its high temperature resistance is also outstanding. It can withstand high temperature environments up to 650 ℃, making it an ideal insulation choice for high-temperature pipelines commonly found in industries such as metallurgy, power, and petrochemicals. Even under prolonged high-temperature conditions, the physical and chemical properties of the material remain stable and will not deteriorate due to high temperatures, providing reliable insulation protection for the pipeline at all times.

The production process of high-density calcium silicate pipeline insulation material from Rosetexwool is rigorous and scientific. The main raw materials are selected from high-quality calcium oxide and quartz sand, which are finely ground into powder and subjected to strict filtration processes to remove impurities, ensuring the purity and stability of the raw material composition. During the production process, special reinforcing fibers are added, and then the mixed raw materials are sent to the reaction kettle for thorough reaction. After the reaction is completed, it is injected into a specific mold for pressure molding, and then the temperature and time during the drying process are precisely controlled through advanced tunnel kiln drying technology, so that the product not only obtains sufficient strength but also maintains good toughness, ensuring high quality of the product from the source.

In the application field, this product is widely applicable to multiple industries. In the metallurgical industry, it can be applied to the insulation of high-temperature flue gas ducts and hot air pipelines in equipment such as heating furnaces, homogenization furnaces, stepper furnaces, annealing furnaces, etc; In the petrochemical industry, heating furnaces, ethylene cracking furnaces, hydrogenation furnaces, catalytic cracking furnaces, etc. all rely on their insulation protection; In the cement industry, equipment such as decomposition furnaces, preheaters, tertiary air ducts, and kiln hoods can also benefit from their excellent performance.

Rosewool Insulation Refractory Co.,Ltd produces high-quality high-density calcium silicate pipeline insulation materials with advanced production technology and strict quality control. Whether in terms of insulation performance, strength, or high temperature resistance, it has demonstrated outstanding performance, providing reliable and efficient solutions for pipeline insulation needs in various industries. Choosing high-density calcium silicate pipeline insulation material from Rosetexwool means choosing efficient, energy-saving, and durable insulation guarantee.

-%E6%8B%B7%E8%B4%9D.jpg)