Rosewool Insulation Refractory Co.,Ltd.

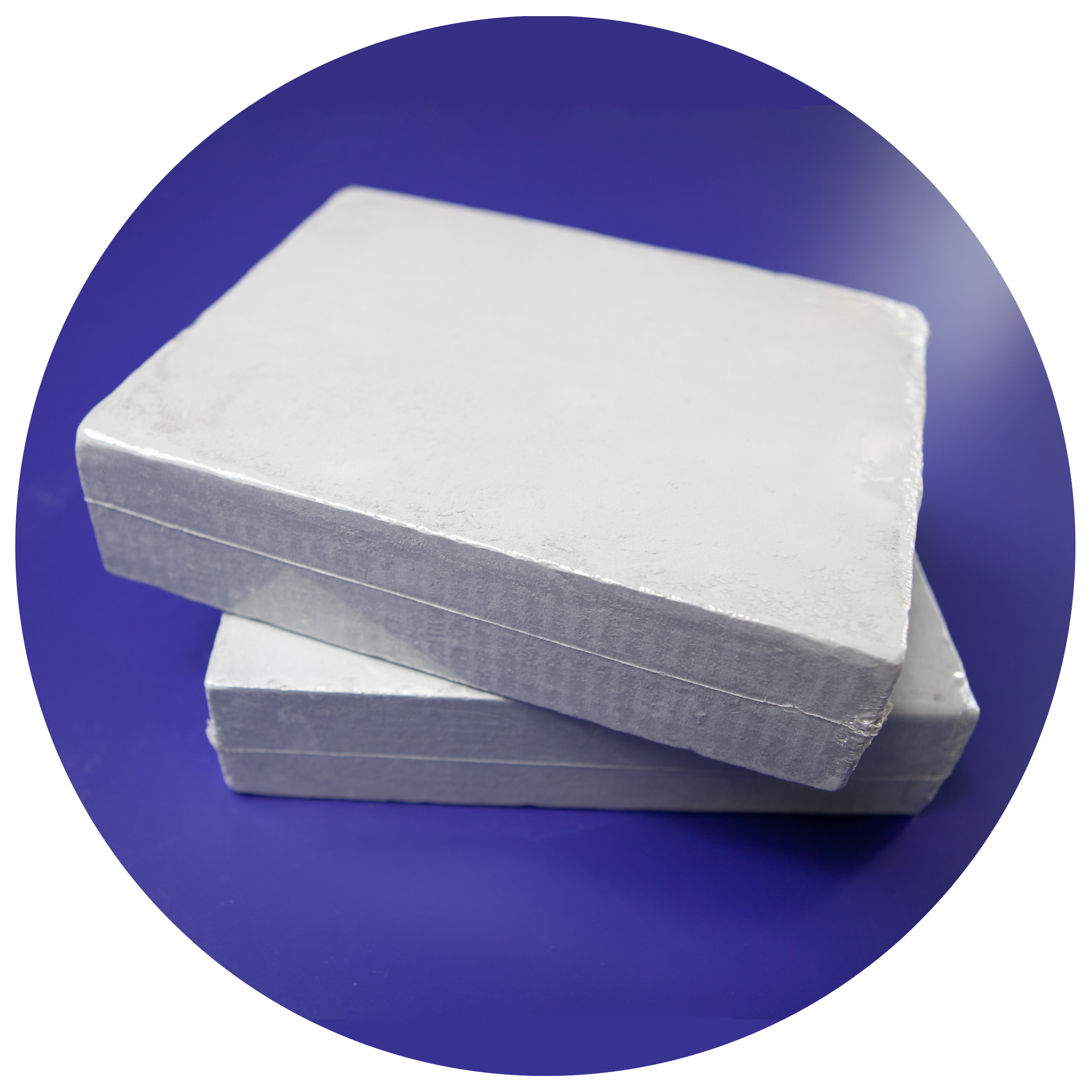

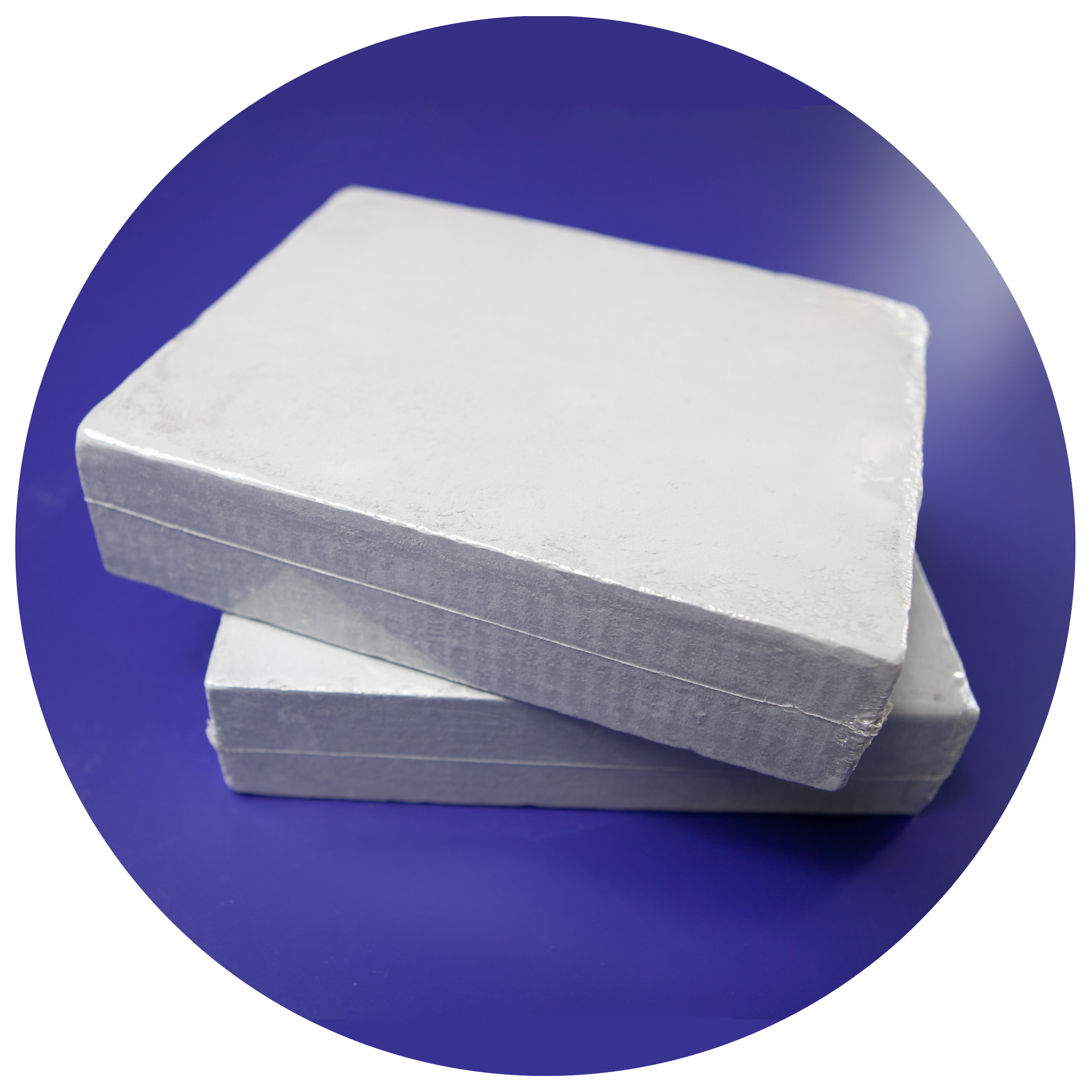

| Items \ Product | Calcium silicate board |

| Classified Tem (℃) | 1000℃/1832℉ |

| Density (kg/m³) | 200-500 |

| Bending Strength (Mpa) | ≥0.5 |

| Conpressive Strength (Mpa) | ≥0.9 |

| Thermal Conductivity (w/m.k) | ≤0.056 |

| Linear Shrinkage (%) | ≤1.5 |

| Max. working Tem. (℃) | 650/1000/1100 |

| Size (mm) | 1000*500/600*300 |

.jpg)