What factory areas can ultrafine glass wool be applied to? In industrial production, insulation, noise reduction, sound insulation, and fire safety are the core requirements of many factory areas. Ultra fine glass wool, with its lightweight, efficient, and multifunctional characteristics, has become an ideal supporting material for various types of factory areas such as power, chemical, metallurgical, electronic, and food processing. Rosewool Insulation Refractory Co.,Ltd has been deeply involved in the industry for many years, creating a series of ultra-fine glass wool products specially customized for complex environments in industrial plants, and has won recognition from various enterprises for its stable performance.

The application scenarios of ultrafine glass wool cover key parts of various industrial plants: in power plants, it can be used for insulation of boilers, pipelines, and steam turbines, reducing heat loss and improving energy utilization efficiency; In the chemical plant area, the insulation and anti-corrosion coating of reaction vessels, storage tanks, and conveying pipelines are adapted to resist chemical medium erosion and ensure stable operation of equipment; In the metallurgical plant area, it is suitable for flue insulation and workshop sound insulation of blast furnaces and converters, reducing high temperature radiation and noise pollution; In the electronic factory area, it can be used as insulation and sound insulation materials for computer rooms and control rooms, creating a constant temperature and quiet working environment; In food processing plants, it can be used for insulation and heat preservation in cold storage and baking workshops to maintain stable production temperatures. In addition, it is widely used in equipment insulation, ceiling sound insulation, wall filling and other scenarios in factories such as mechanical manufacturing and building materials processing.

Rosewool Insulation Refractory Co.,Ltd's ultra-fine glass wool has three core advantages:

firstly, it has dual high efficiency in insulation and sound insulation, with fine fiber diameter, high porosity, extremely low thermal conductivity, and insulation effect far exceeding traditional materials. At the same time, it can effectively absorb sound waves and reduce noise pollution in the factory area;

Secondly, it has excellent fire safety performance, reaching the non combustible A-level standard, and does not produce toxic smoke in case of fire, which meets the strict fire safety requirements of industrial plants;

Thirdly, it is lightweight, environmentally friendly, and easy to construct. The material is loose and lightweight, and can be cut and laid freely. The construction efficiency is high, and there is no formaldehyde or odor, which meets environmental standards and does not affect the factory environment and personnel health.

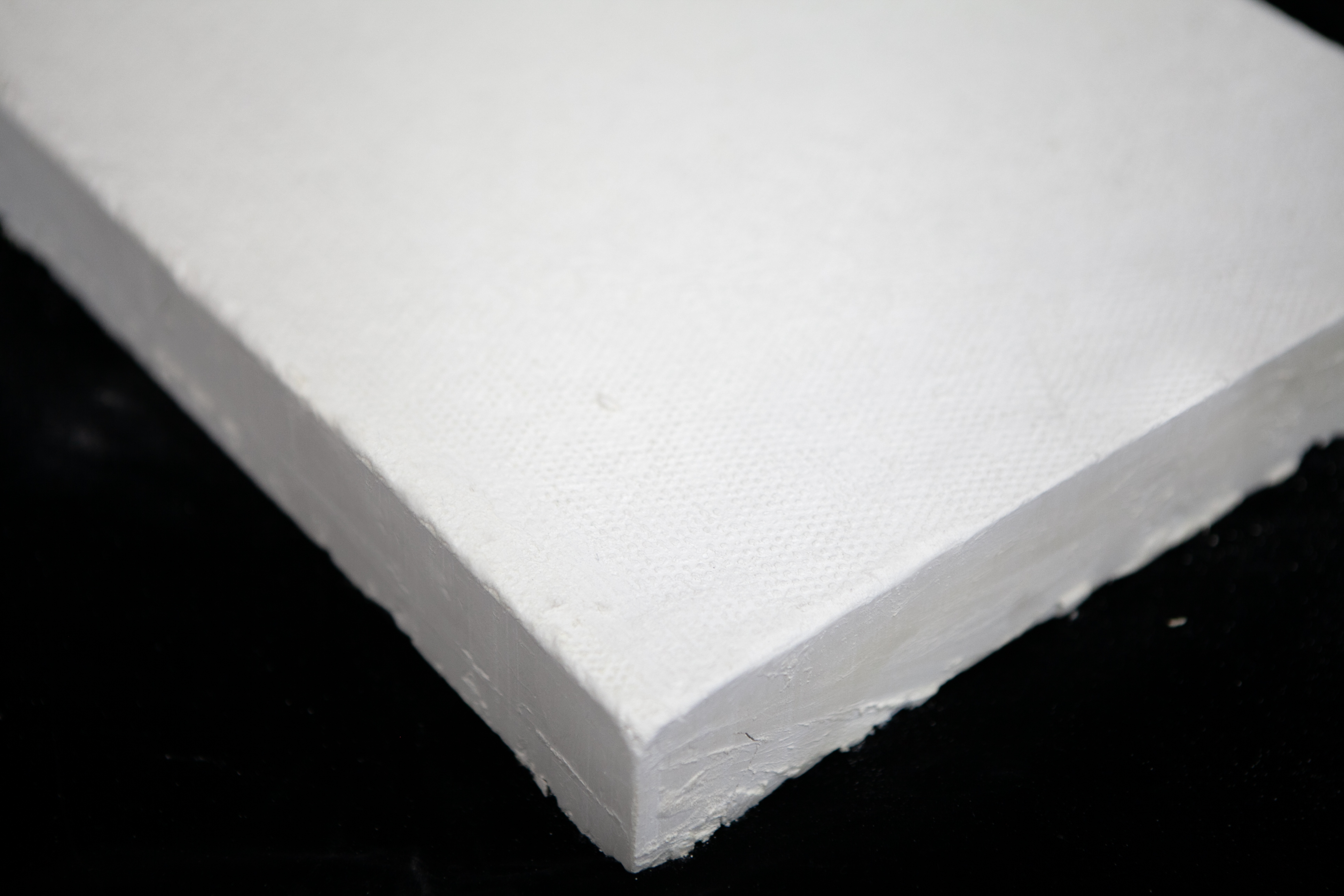

Introduction to Glass Wool Blanket

Centrifugal glass wool felt is designed to meet the needs of large-scale laying of the coil, not only maintain the characteristics of thermal insulation, but also has a very excellent shock absorption, sound absorption characteristics, especially in the low frequency and a variety of vibration noise environment. With a good absorption effect, is conducive to reduce noise pollution, improve the working environment.

There is aluminum foil veneer glass wool felt, with a strong ability to heat radiation, used in high temperature workshop, control room, the engine room wall, compartment and flat top lining material.

Choosing to cooperate with Rosewool Insulation Refractory Co.,Ltd can enjoy multiple exclusive advantages: direct supply from the manufacturer eliminates intermediate links, and high-quality products are supplied at factory prices, with outstanding cost-effectiveness; A professional team customizes ultra-fine glass wool that is suitable for different factory conditions, temperatures, media, and other requirements; Relying on the advantages of Zhengzhou's transportation hub, the logistics network radiates across the country to ensure fast delivery of goods; Provide full process services from product selection, construction plan guidance to after-sales maintenance, and solve problems for customers throughout the process.

What factory areas can ultrafine glass wool be applied to? Whether it is a metallurgical plant under high-temperature conditions or an electronic plant that requires constant temperature and silent operation, Rosewool Insulation Refractory Co.,Ltd ultrafine glass wool can accurately adapt to the needs. Build strong insulation, sound insulation, and fire barriers for various industrial plants with high-quality performance, reasonable prices, and attentive services. If you need to know specific application solutions or quotations, please feel free to contact us at any time, and we will provide customized services for you!

.jpg)