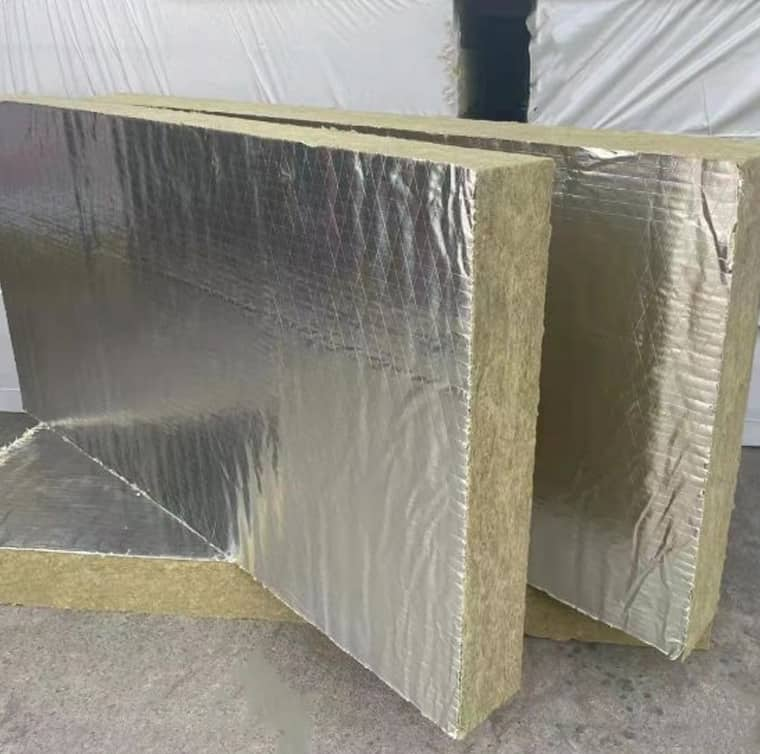

Rosewool Insulation Refractory Co.,Ltd.

| Performance | Indicators |

| Shot content ( Particle diameter ≥0.25mm) | ≤ 12.0 % |

| The average diameter of fiber | ≤7.0 μm |

| Density Tolerance | ± 15% |

| Thermal Conductivity ( average temperature 70℃±52℃),W/(m/K) | ≤ 0.044 |

| Thermal load contraction temperature (more than 60kg/m3) | ≤ 600 ℃ |

| Moisture | ≤0.5% |

| Combustion performance | Not burning (Class A) |

| Organic content | ≤ 4.0% |

-拷贝.jpg)