Ceramic fiber modules have become indispensable in numerous high - temperature industrial applications. Understanding how they function is crucial for industries seeking to optimize their operations, improve energy efficiency, and ensure the longevity of their equipment.

1. Composition and Structure Basics

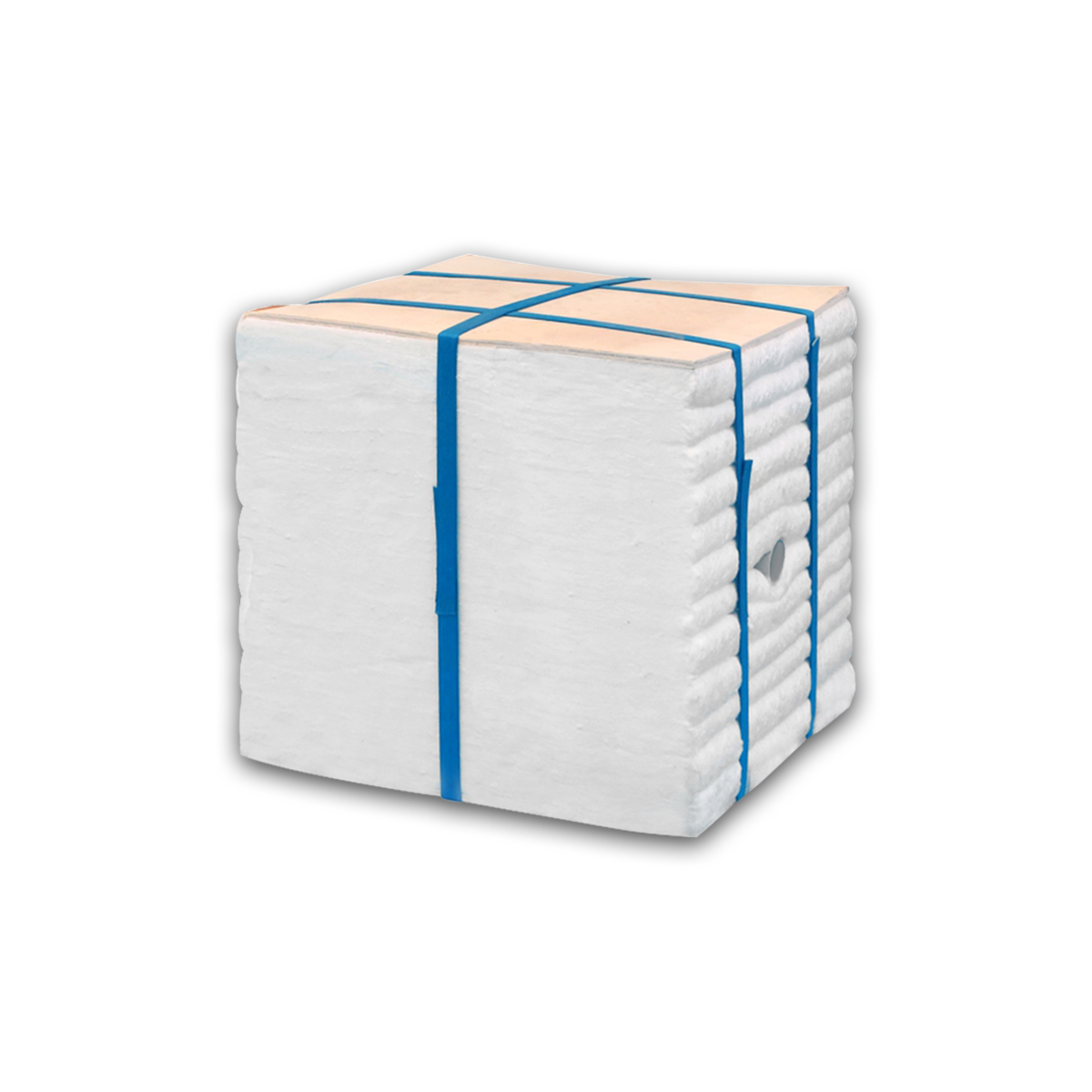

Ceramic fiber modules are primarily composed of ceramic fibers, usually made from aluminum silicate. These fibers are processed through techniques like needle punching, which interlocks them to form a dense and structured mat. This mat is then compressed and shaped into modules of various sizes and configurations. The unique structure of the ceramic fiber module is the foundation of its functionality. The individual fibers are extremely fine, creating a large surface area within the module. This characteristic plays a significant role in its thermal and physical properties.

2. Thermal Insulation Mechanism

One of the most important functions of a ceramic fiber module is thermal insulation. The low thermal conductivity of ceramic fibers is the key to this. When heat is applied to one side of the module, the ceramic fibers impede the transfer of heat to the other side. The air pockets trapped between the fibers further enhance this insulating effect. Air is a poor conductor of heat, and these pockets act as additional barriers. In high - temperature applications, such as industrial furnaces, the ceramic fiber module lines the interior walls. Heat generated inside the furnace tries to escape, but as it reaches the ceramic fiber module, the transfer of heat is significantly slowed down. This not only keeps the heat within the furnace where it is needed but also reduces the amount of energy required to maintain the desired temperature, resulting in substantial energy savings.

3. Resistance to High Temperatures

Ceramic fiber modules are designed to withstand extremely high temperatures. The aluminum silicate fibers from which they are made have a high melting point and excellent resistance to thermal degradation. When exposed to high - temperature environments, the module does not melt or lose its structural integrity easily. For example, in a glass - melting kiln, where temperatures can reach well over 1000°C, the ceramic fiber module remains stable. It maintains its shape and functionality, protecting the surrounding structure from the intense heat. This high - temperature resistance also allows for rapid temperature changes without causing the module to crack or break. In processes where quick heating and cooling cycles are involved, such as in some heat - treatment applications, the ceramic fiber module can endure these thermal shocks, ensuring the continuous operation of the equipment.

4. Chemical Stability and Protection

In many industrial settings, chemical substances are present that can corrode or damage equipment. Ceramic fiber modules exhibit good chemical stability. They are resistant to most acids, alkalis, and other common industrial chemicals. When used to insulate equipment in the petrochemical industry, for instance, the module protects the underlying metal surfaces from chemical attack. This not only safeguards the equipment but also extends its service life, reducing the need for frequent repairs and replacements. The chemical resistance of the ceramic fiber module also helps in maintaining its thermal insulation properties over time. Chemical corrosion can degrade the structure of materials, which in turn can affect their thermal performance. By resisting chemical attack, the ceramic fiber module ensures consistent thermal insulation in harsh chemical environments.

5. Contribution to Energy Efficiency

As mentioned earlier, the thermal insulation properties of ceramic fiber modules play a major role in energy efficiency. In addition to reducing heat loss, they also contribute to faster heating and cooling processes in some applications. In a batch - type furnace, for example, the ceramic fiber module enables quicker heating up to the required temperature because less heat is lost to the surroundings. Once the heating process is complete, the module also helps in maintaining the temperature with less energy input. When it comes time to cool down the furnace, the insulation provided by the module prevents external heat from entering, allowing for more efficient cooling. Overall, this leads to reduced energy consumption, lower operating costs, and a more sustainable industrial operation.

6. Installation and Adaptability

The way

ceramic fiber modules are installed also impacts their functionality. They are relatively lightweight compared to traditional refractory materials, making them easier to handle and install. Modules can be customized to fit various shapes and sizes of equipment. They can be cut and shaped on - site to accommodate specific installation requirements. This adaptability ensures that the module can be installed in a way that maximizes its effectiveness. For example, in irregularly shaped industrial reactors, the ceramic fiber module can be tailored to provide comprehensive insulation coverage, ensuring that all areas are protected from heat and chemical exposure.

In conclusion, ceramic fiber modules work through a combination of their unique composition, structure, and properties. Their ability to insulate against heat, withstand high temperatures, resist chemicals, and contribute to energy efficiency makes them a valuable asset in a wide range of industrial applications. Understanding how they work is essential for industries to make the most of these modules and optimize their processes.