Rosewool Insulation Refractory Co.,Ltd.

| Type | STD Module | HP Module | HZ Module | |

| Classified Temperature | 1260℃ (2300℉) |

1260℃ (2300℉) |

1430℃ (2606℉) |

|

| Working Temperature | 1050℃ (1922℉) |

1100℃ (2012℉) |

1350℃ (2462℉) |

|

| Density(kg/m3) | 160-260 (13-16 lb/ft3) |

|||

| Linear Shrinkage 24hrs | ≤2.5 1000℃/2012℉ |

≤2.5 1100℃/2012℉ |

≤3.5 1350℃/2462℉ |

|

| Thermal Conductivity(W/m.k) | 400℃ (752℉) |

0.09 | 0.101 | 0.118 |

| 500℃ (930℉) |

0.119 | 0.12 | 0.149 | |

| 600℃ (1112℉) |

0.152 | 0.175 | 0.195 | |

| Chemical Composition % | Al2O3 | ≥44 | ≥45 | ≥34 |

| SiO2 | ≥52 | ≥54 | ≥50 | |

| ZrO2 | ≥15 | |||

| Fe2O3 | ≤1.0 | ≤0.5 | ≤0.5 | |

| K2O+Na2O | ≤1.0 | ≤0.2 | ≤0.2 | |

| Size | 300/600*300*200-350 mm | |||

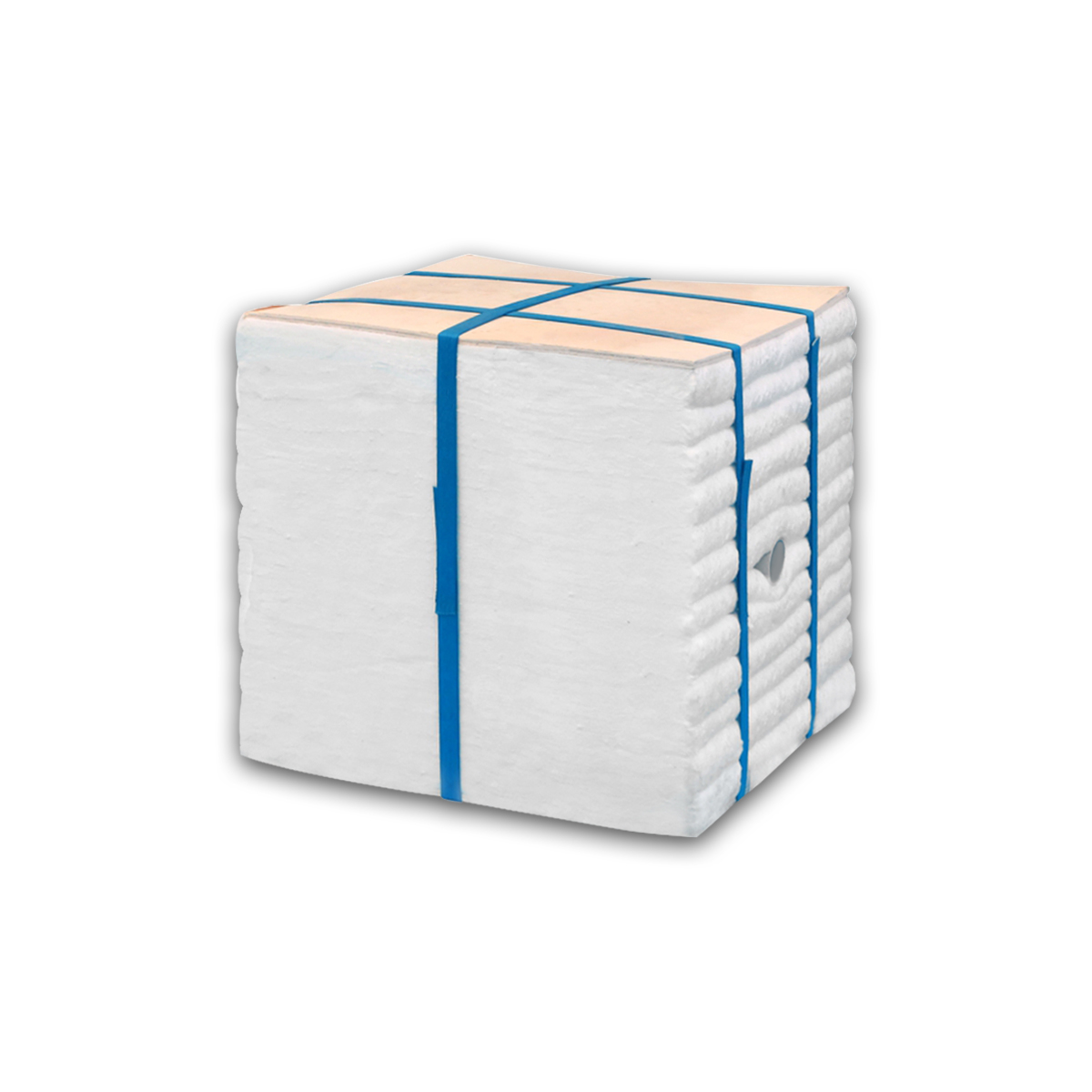

| Packing | plastic bag together with Carton or Pallet | |||

.jpg)