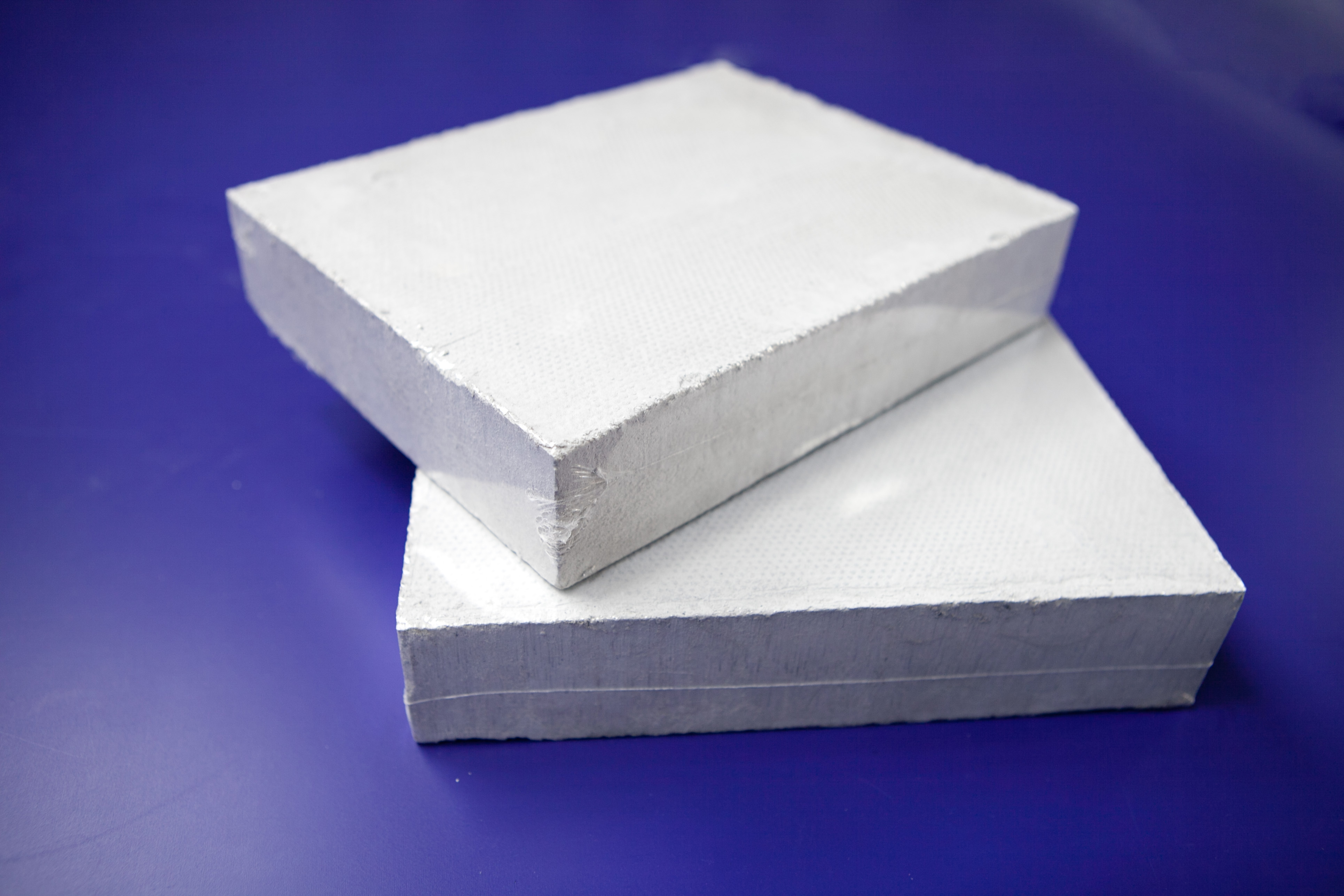

Glass wool insulation boards are a staple in modern construction, valued for their thermal efficiency, fire resistance, and soundproofing properties. However, cutting them safely requires precision and precautions—improper techniques can lead to wasted materials, uneven edges, or even health risks from airborne fibers. Whether you’re a DIY enthusiast or a professional contractor, this guide will walk you through the safest and most effective methods to cut glass wool insulation boards.

Why Safety Matters When Cutting Glass Wool

Glass wool is made from fine glass fibers, which can irritate the skin, eyes, and respiratory system if inhaled or touched. Cutting releases tiny particles into the air, making proper safety gear and ventilation non-negotiable. Additionally, uneven cuts can compromise the insulation’s performance, leading to energy loss or structural gaps. Mastering safe cutting ensures both personal protection and optimal material use.

Tools You’ll Need for Safe Cutting

Before starting, gather these essential tools to ensure precision and safety:

- Protective Gear: Nitrile gloves (to avoid fiber sticking to skin), safety goggles or a face shield (to block flying fibers), a dust mask or N95 respirator (to prevent inhalation), and long-sleeved clothing (to minimize skin exposure).

- Measuring Tools: A sturdy tape measure, carpenter’s pencil, or marker for accurate markings.

- Cutting Tools:

- Circular Saw: Ideal for straight, long cuts (use a fine-tooth carbide blade to reduce splintering).

- Utility Knife or Shear: Perfect for thin boards or detailed cuts (ensure the blade is sharp to avoid crushing fibers).

- Insulation Cutting Jigsaw: A specialized tool with a fine-tooth blade for curved or intricate shapes.

- Heat Gun (Optional): Softens fibers at the cut edge to reduce fraying (use caution to avoid melting the material).

Step-by-Step: How to Safely Cut Glass Wool Insulation Boards

1. Prepare Your Workspace

- Work in a well-ventilated area (outdoors or near an open window) to reduce airborne fiber concentration.

- Cover the floor with a drop cloth to catch dust and debris, making cleanup easier.

- Secure the glass wool board firmly using clamps or a non-slip mat to prevent slipping during cutting.

2. Measure and Mark the Cut

- Use a tape measure to mark your desired cut line. For straight cuts, snap a chalk line or use a straight edge (e.g., a level) to guide your tool.

- Double-check measurements to avoid errors—precision here saves time and materials later.

3. Put on Protective Gear

- Wear gloves, goggles, a respirator, and long sleeves before handling the saw or knife. Fibers can settle on skin or clothing, so avoid loose sleeves that might catch debris.

4. Cut the Board

- For Circular Saws: Set the blade depth slightly deeper than the board’s thickness (1/8–1/4 inch extra). Start the saw, align the blade with the marked line, and cut slowly at a steady pace. Keep both hands on the saw to maintain control.

- For Utility Knives/Shears: Score the board along the marked line with a sharp blade (3–4 passes for thin boards). Apply firm, even pressure to avoid tearing. For thicker boards, use shears designed for fiberglass/glass wool.

- For Curved Cuts: Use a jigsaw with a fine-tooth blade. Guide the blade slowly along the marked curve, keeping the base plate flat against the board.

5. Smooth Edges (Optional)

- After cutting, use a sanding block or utility knife to smooth rough edges. Avoid pressing too hard—this prevents fiber breakage and reduces dust.

- For a cleaner finish, use a heat gun (set to low heat) to slightly melt the cut edges, which helps fibers adhere and reduces fraying.

6. Clean Up Safely

- Turn off tools and unplug them before cleaning.

- Use a vacuum with a HEPA filter to remove fine dust (never sweep, as it redistributes fibers).

- Wipe surfaces with a damp cloth to capture remaining particles.

- Dispose of waste in sealed bags (check local regulations for insulation disposal).

Pro Tips for Safe and Efficient Cutting

- Wet Cutting (Optional): Lightly mist the board with water before cutting to suppress dust. This is ideal for large projects but ensure the board dries fully before installation (excess moisture can reduce insulation performance).

- Use a Guide Rail: For circular saws, attach a guide rail to the board to keep cuts straight and reduce errors.

- Work in Stages: If cutting multiple boards, take short breaks to avoid fatigue—tiredness increases the risk of mistakes.

Common FAQs About Cutting Glass Wool

Q: Does cutting glass wool release toxic fumes?

A: No, glass wool is non-toxic, but inhaling fine fibers can irritate the lungs. Always wear a respirator.

Q: How do I prevent the board from slipping while cutting?

A: Use clamps to secure the board, or place a non-slip mat underneath. For wet cutting, ensure the surface is stable and not slippery.

Q: Can I cut glass wool with a handsaw?

A: Yes, but it’s slower and less precise. Opt for a utility knife or jigsaw for better control.

Final Thoughts

Cutting glass wool insulation boards safely hinges on preparation, proper tools, and protective gear. By following these steps, you’ll minimize health risks, reduce material waste, and ensure clean, professional-looking cuts that perform reliably in your construction or renovation project.