Rock wool board is a versatile insulation material known for its excellent fire resistance, thermal insulation, and sound absorption properties. When selecting high-quality rock wool board, several factors should be considered to ensure you are getting a product that meets your needs and complies with safety standards.

1. Core Purchasing Standards and Certifications

Certification Marks

- Fire Resistance Level: Ensure the rock wool board has an A1 fire resistance certification, which indicates that it is non-combustible and can withstand high temperatures without contributing to the spread of fire.

- Environmental Certifications: Look for certifications such as RoHS, REACH, and ISO 14001, which indicate that the product meets high environmental standards.

Physical Properties

- Thermal Conductivity: The thermal conductivity should be ≤0.043 W/(m·K), ensuring effective thermal insulation.

- Tensile Strength: The tensile strength should be ≥4.0 kN/m, indicating the board’s durability and ability to withstand mechanical stress.

2. Supplier Selection

Brand Reputation

Prioritize suppliers with a strong reputation and complete certifications. Established brands are more likely to offer high-quality products and reliable customer support.

Customization Capability

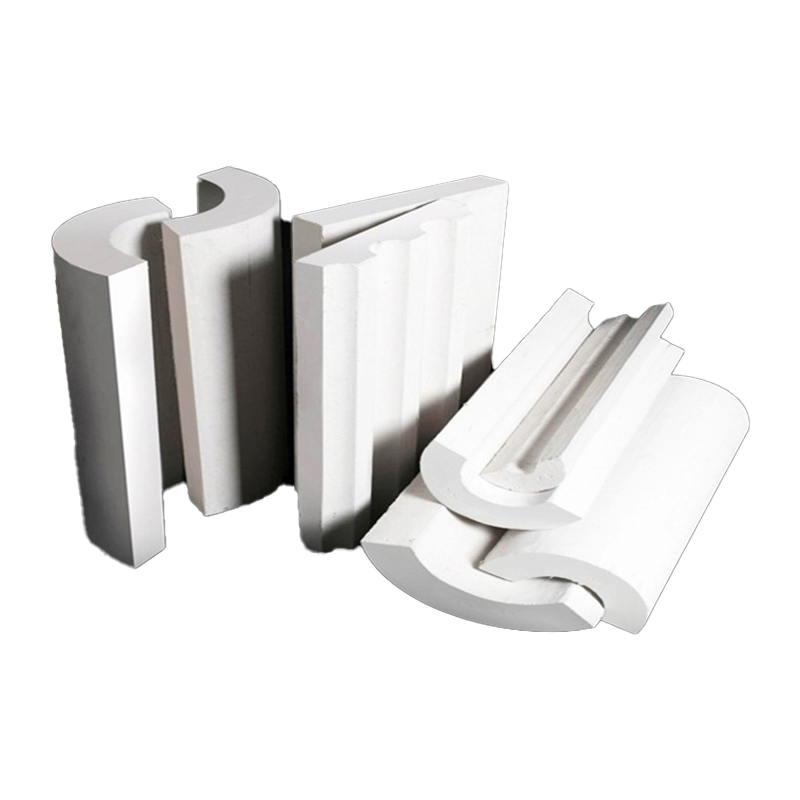

Ensure the supplier can customize the rock wool board according to your project requirements, including thickness, size, density, and surface treatments like aluminum foil coating.

3. Key Properties to Look For

Fire Resistance

Rock wool board should have a melting point of approximately 1177°C (2150°F) and be classified as non-combustible. It should also meet fire safety standards such as ASTM E 136, CAN/ULC-S114, and ASTM E 84.

Thermal Performance

The board should offer low thermal conductivity (e.g., 0.042 W/m·K) and high thermal resistance (R-value), ensuring effective insulation and energy efficiency.

Acoustic Performance

For applications requiring soundproofing, the rock wool board should have a high Noise Reduction Coefficient (NRC) and Sound Transmission Class (STC) rating.

Moisture Resistance

High-quality rock wool board should be water-repellent and resistant to mold and mildew growth, ensuring long-term performance in damp or humid conditions.

4. Practical Recommendations

Climate Considerations

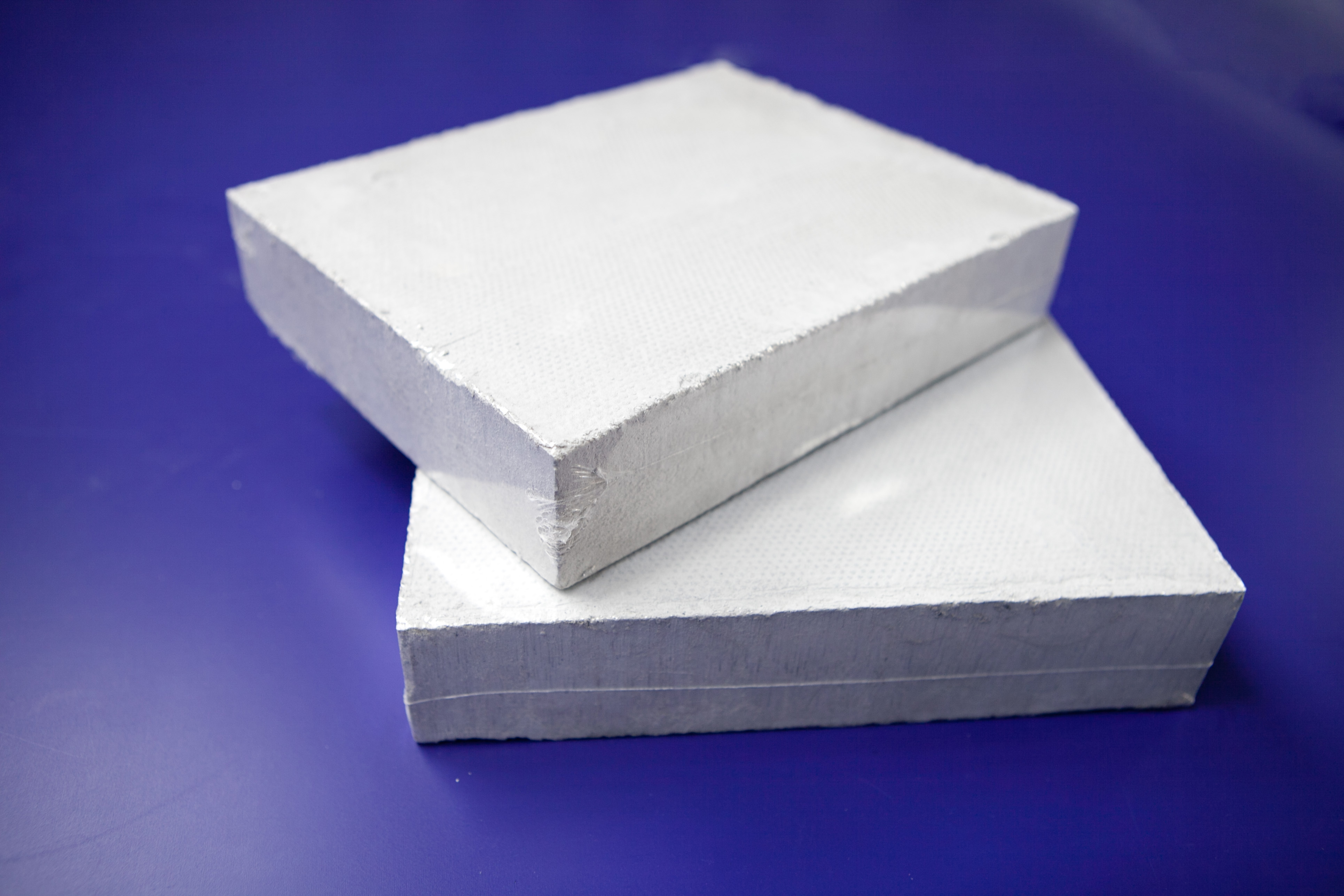

- In colder climates, prioritize boards with higher thickness and lower thermal conductivity to enhance insulation.

- In warm and humid areas, choose water-repellent or coated products to prevent moisture issues.

Application-Specific Needs

- For soundproofing, select boards with a density of 40-60 kg/m³ and a thickness of around 50 mm.

- For areas at risk of fire (e.g., boiler rooms), high-density rock wool board is essential due to its superior fire resistance.

Conclusion

Choosing high-quality

rock wool board involves evaluating certifications, physical properties, supplier reputation, and specific project requirements. By prioritizing these factors, you can ensure the rock wool board you select offers superior fire resistance, thermal insulation, and acoustic performance, contributing to a safer and more efficient building environment.