In the global construction and building materials industry, rock wool board has emerged as a go-to solution for thermal insulation, fire resistance, and acoustic optimization. Among the leading suppliers, China Rosewool—a trusted brand specializing in premium rock wool products—has gained international recognition for delivering high-performance, cost-effective insulation solutions. Whether you’re working on a residential, commercial, or industrial project, understanding the benefits, applications, and selection criteria for China Rosewool rock wool boards can help you make informed decisions.

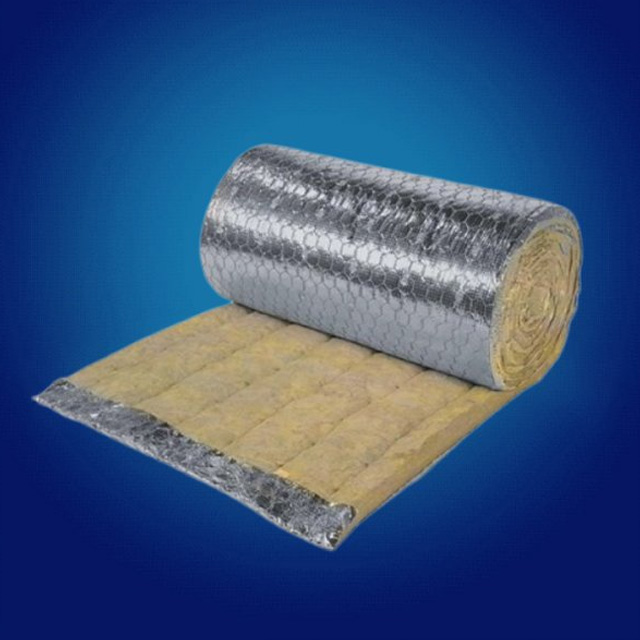

Rock wool, also known as mineral wool, is a type of insulation material made from molten basalt (volcanic rock) melted at high temperatures (around 1,450°C) and spun into fine fibers. These fibers are then compressed into dense boards using binders and pressed under controlled conditions. Rosewool, a specialized variant, is engineered to enhance thermal efficiency, fire resilience, and durability, making it ideal for modern construction needs.

Key properties of Rosewool rock wool boards include:

China has become a global hub for rock wool production, thanks to its abundant basalt reserves, advanced manufacturing technology, and commitment to quality. Here’s why China Rosewool leads the pack:

China Rosewool sources basalt from high-purity quarries, ensuring consistent fiber strength and thermal performance. Unlike lower-quality imports, their boards use eco-friendly binders (low volatile organic compounds, VOCs) that comply with strict environmental regulations (e.g., REACH, RoHS).

Equipped with automated production lines, China Rosewool ensures precise control over density (40–200 kg/m³), thickness (30–200mm), and fiber diameter (3–5μm). This consistency minimizes thermal bridging and maximizes insulation efficiency.

All Rosewool products undergo rigorous testing to meet global standards:

Thanks to China’s efficient supply chain and economies of scale, Rosewool rock wool boards offer competitive pricing without compromising quality. This makes them a preferred choice for large-scale projects, from high-rise buildings to industrial warehouses.

Rosewool rock wool boards are versatile and adaptable to diverse construction needs:

With numerous suppliers claiming to offer “premium” rock wool boards, here’s how to identify reliable partners:

China Rosewool rock wool boards combine cutting-edge technology, sustainable practices, and uncompromised performance, making them a top choice for global construction projects. Whether you prioritize fire safety, energy efficiency, or cost-effectiveness, these boards deliver on all fronts. By partnering with certified suppliers and prioritizing key features like material purity and certification, you can ensure your project benefits from long-lasting, high-performance insulation.

-拷贝.jpg)