A ceramic fiber blanket is a high-temperature insulation product that plays a vital role in industrial furnaces, kilns, boilers, and even residential heating systems. But how exactly does it work? In this article, we’ll explain how ceramic fiber blanket works, its thermal insulation mechanism, and why it’s widely used in heat-intensive applications.

Whether you’re an engineer, a DIYer, or someone looking for efficient insulation solutions, this guide will give you the insights you need.

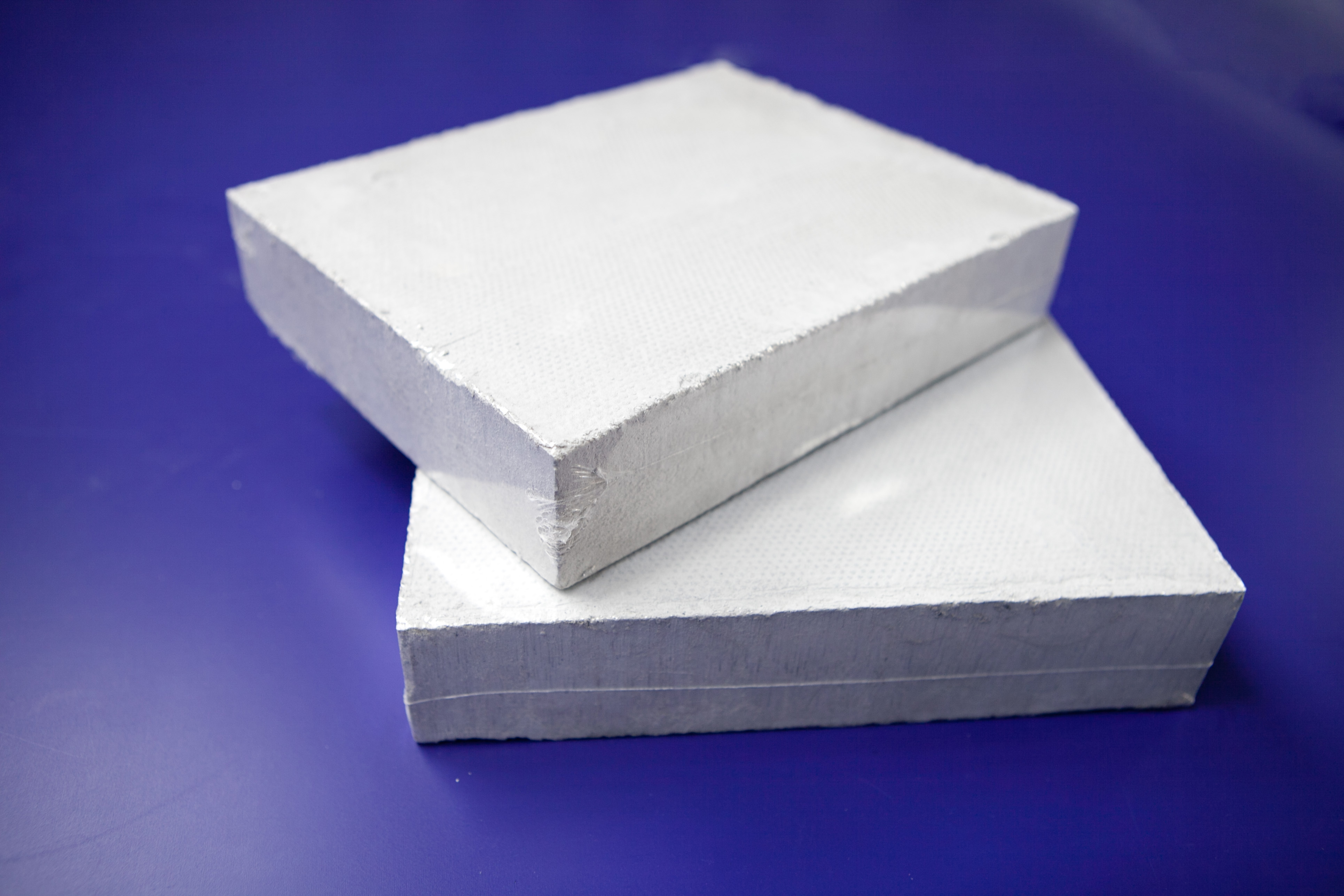

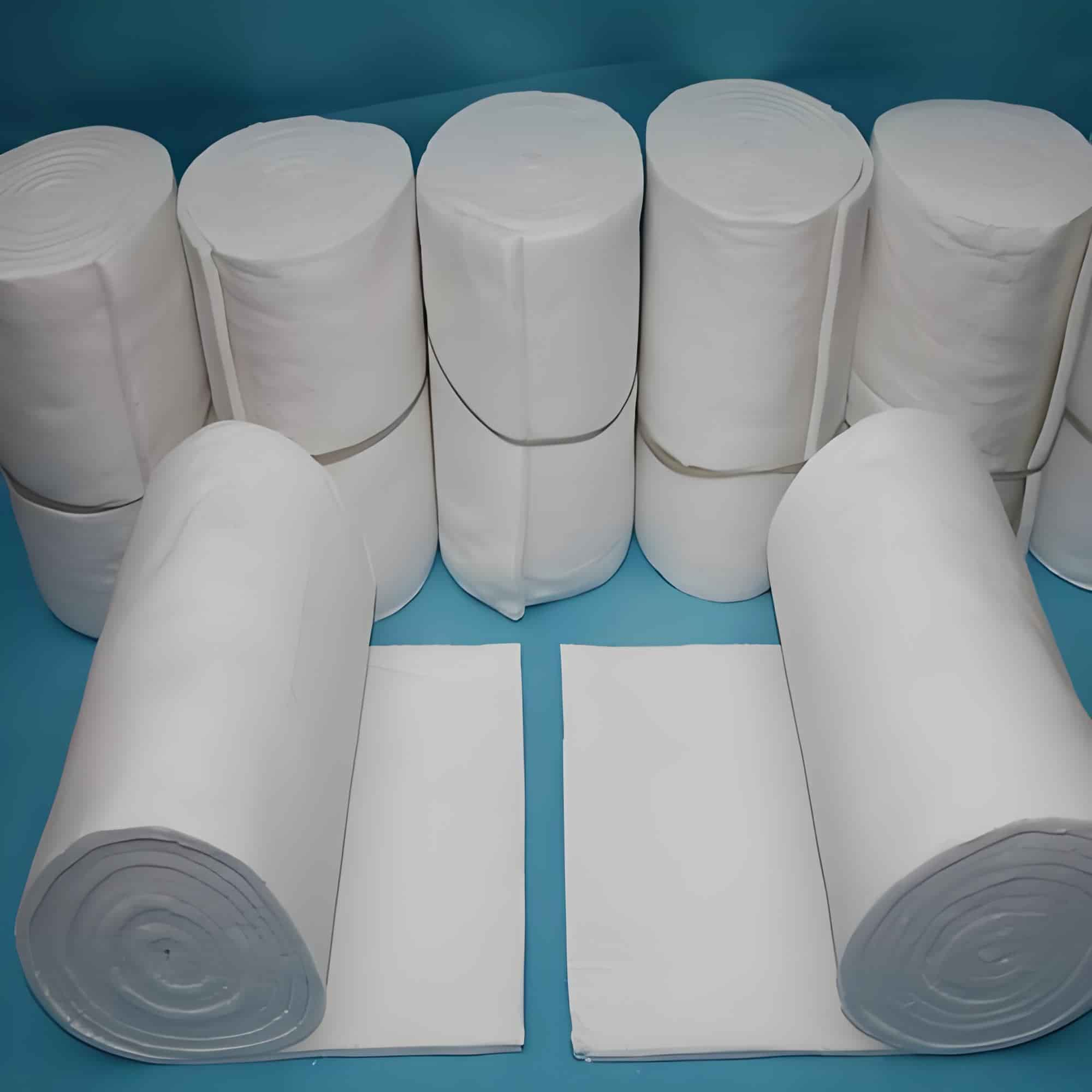

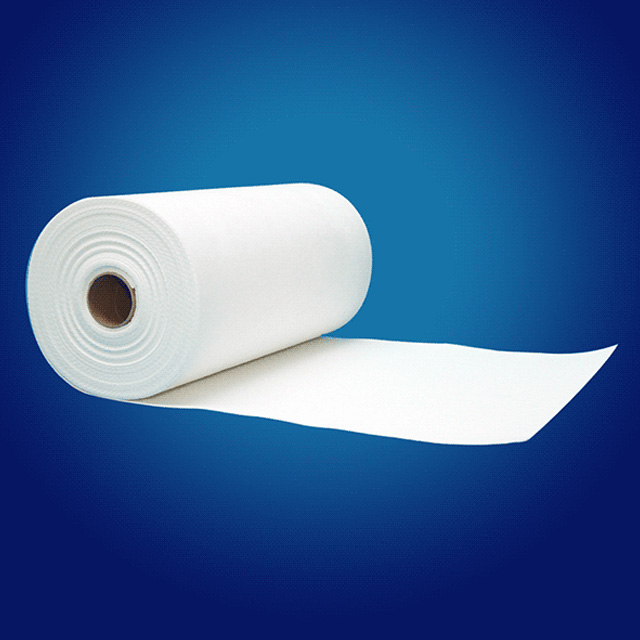

A ceramic fiber blanket (also known as refractory ceramic fiber blanket, or RCF blanket) is made from alumina (Al₂O₃) and silica (SiO₂) fibers produced by melting and spinning or blowing the raw material into lightweight, flexible blankets. These blankets are designed to resist extremely high temperatures, often ranging from 1260°C (2300°F) to 1430°C (2600°F).

The working principle of ceramic fiber blankets is based on thermal insulation through low thermal conductivity and high heat resistance. Here’s how it works step by step:

Ceramic fibers are inherently poor conductors of heat. When the blanket is exposed to high temperatures, the fibers create a barrier that slows down the transfer of heat from the hot surface to the cooler side.

✅ This minimizes heat loss and improves energy efficiency in industrial processes.

The fiber structure of the blanket includes countless tiny air pockets between the fibers. Air is a poor heat conductor, so these trapped air pockets act as natural insulation and further reduce heat transfer.

✅ Think of it like a thermal version of a down jacket—lightweight, but incredibly insulating.

Ceramic fibers can reflect radiant heat due to their high emissivity properties. In applications like kilns or forges, this helps maintain internal temperatures while protecting the external environment.

The structure of ceramic fiber allows it to handle rapid temperature changes without cracking or breaking down. This is essential in applications where temperatures cycle frequently.

✅ This makes ceramic fiber blankets ideal for environments like metal foundries and glass processing plants.

| Feature | How It Works |

|---|---|

| Low Density | Minimizes heat absorption, speeds up heat-up and cool-down times |

| Flexibility | Allows for easy installation on curved or irregular surfaces |

| Chemical Stability | Resists most acids, alkalis, and corrosive gases |

| Low Heat Storage | Reduces energy consumption during cycling operations |

Because of its thermal efficiency, ceramic fiber blanket is commonly used in:

Industrial furnaces and kilns (reducing fuel consumption)

Boilers and pipe insulation (preventing heat loss)

Fire protection barriers (resisting flame penetration)

Back-up insulation behind refractory bricks

Pizza ovens and wood-burning stoves (retaining heat for even cooking)

No, but it significantly slows down heat transfer, helping to maintain desired temperatures while protecting surrounding surfaces.

Yes, especially for high-temperature applications. Ceramic fiber blankets can withstand much higher temperatures than fiberglass.

Common thicknesses range from 1/2 inch to 2 inches. The ideal thickness depends on your application’s temperature range and insulation goals.

So, how does the ceramic fiber blanket work? It uses a combination of low thermal conductivity, air entrapment, radiant heat reflection, and thermal shock resistance to provide powerful and lightweight insulation. This makes it one of the most efficient and versatile solutions for both industrial and residential high-temperature environments.

If you're looking for reliable insulation that saves energy, enhances safety, and withstands intense heat, a ceramic fiber blanket may be exactly what you need.