Calcium silicate board is a versatile and high-performance building material that has gained widespread recognition and application in the construction industry. Its unique properties make it an ideal choice for a variety of applications, ranging from residential to commercial and industrial projects. This article will explore the numerous advantages of calcium silicate boards, highlighting why they are a preferred material for modern construction.

Fire Resistance

One of the most significant advantages of

calcium silicate boards is their exceptional fire resistance. These boards are non-combustible and can withstand extremely high temperatures without degrading or emitting toxic fumes. This makes them an ideal choice for fire-rated walls, partitions, and ceilings, providing critical protection in case of a fire. Calcium silicate boards meet stringent fire safety standards, ensuring the safety of occupants and the integrity of the building structure.

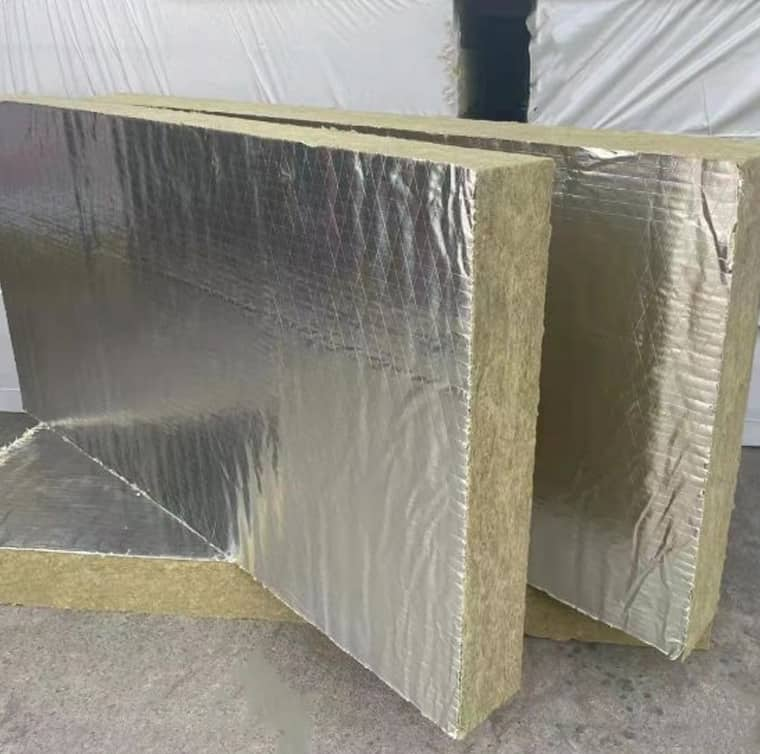

Thermal Insulation

Calcium silicate boards offer excellent thermal insulation properties, helping to maintain consistent indoor temperatures and reduce energy consumption. By effectively reducing heat transfer, these boards contribute to lower heating and cooling costs, making buildings more energy-efficient and environmentally friendly. This is particularly beneficial in regions with extreme weather conditions, where maintaining a comfortable indoor environment is crucial.

Moisture Resistance

Another key advantage of calcium silicate boards is their moisture resistance. Unlike some traditional building materials, calcium silicate boards do not absorb water, making them highly resistant to mold, mildew, and rot. This property is especially valuable in areas with high humidity or where the boards are exposed to moisture, such as bathrooms, kitchens, and basements. The moisture resistance of calcium silicate boards also helps to prevent structural damage and prolong the lifespan of the building.

Sound Absorption

Calcium silicate boards provide effective sound absorption, reducing noise transmission between different spaces. This acoustic benefit is particularly important in residential and commercial buildings where privacy and a quiet environment are essential. By minimizing sound reverberation and blocking external noise, calcium silicate boards create more comfortable and peaceful living and working spaces.

Structural Integrity

Calcium silicate boards are known for their high strength and durability. They can withstand significant mechanical stress and maintain their structural integrity over time. This makes them suitable for use in load-bearing applications and areas where the boards may be subjected to physical impact. The robust nature of calcium silicate boards ensures long-term performance and reduces the need for frequent maintenance or replacement.

Environmental Sustainability

Calcium silicate boards are an environmentally friendly building material. They are made from natural and abundant raw materials, such as calcium oxide and silica, which are sustainably sourced. Additionally, the production process of calcium silicate boards is relatively energy-efficient and generates minimal waste. These boards are also recyclable, further contributing to their eco-friendly appeal. By choosing calcium silicate boards, builders and architects can contribute to sustainable construction practices and reduce the environmental impact of their projects.

Versatility in Applications

Calcium silicate boards are incredibly versatile and can be used in a wide range of applications. They are commonly used for interior and exterior wall cladding, partitions, ceilings, and flooring underlayment. Their ability to be cut and shaped easily allows for customization to fit various architectural designs and requirements. Whether used in residential homes, commercial buildings, or industrial facilities, calcium silicate boards offer a reliable and high-performance solution.

Low Maintenance

Calcium silicate boards require minimal maintenance, making them a cost-effective and hassle-free choice for building owners. Their resistance to moisture, fire, and pests means that they do not need regular painting, sealing, or other treatments. This reduces the overall maintenance costs and ensures that the boards maintain their performance and appearance over time.

Conclusion

The advantages of

calcium silicate boards make them a standout choice in the construction industry. Their fire resistance, thermal insulation, moisture resistance, sound absorption, structural integrity, environmental sustainability, versatility, and low maintenance requirements collectively contribute to their superior performance and reliability. As the demand for sustainable and high-performance building materials continues to grow, calcium silicate boards are likely to remain a popular and preferred choice for builders, architects, and homeowners alike.