Rosewool Insulation Refractory Co.,Ltd.

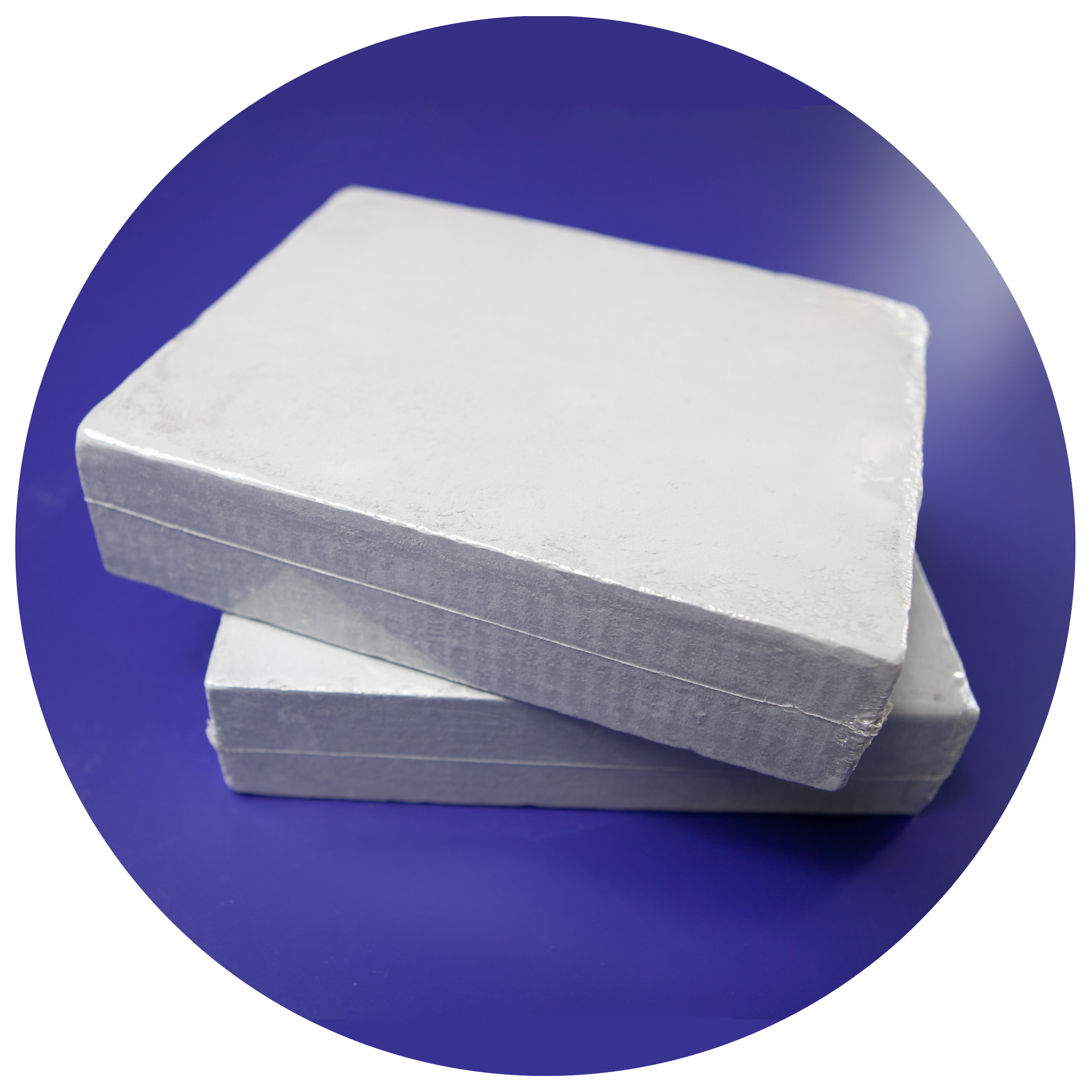

| Items | JDN-1 Nano Insulation Board | JDN-II Nano Insulation Board | JDN-H Nano Insulation Board | |

| Color | Grey | Grey | White | |

| Melting Point | >1200℃ | >1200℃ | >1200℃ | |

| Maximum Operating Temperature | 1000℃ | 1000℃ | 1100℃ | |

| Bulk Density | 600kg/m³±10% | 600kg/m³±10% | 300±10% kg/m³ | |

| Linear Shrinkage(900℃*3h) | ≤-1% | <-1% | ≤-1% | |

| Thermal Conductivity | 300℃ | ≤0.02W/m.k | ≤0.02W/m.k | |

| 600℃ | ≤0.052W/m.k | ≤0.04W/m.k | ≤0.030W/m.k | |

| 1000℃ | ≤0.085W/m.k | ≤0.065W/m.k | ≤0.038W/m.k | |