A revolutionary new technology in ceramic fiber blanket manufacturing has been announced, bringing significant improvements to the material's performance and applications.

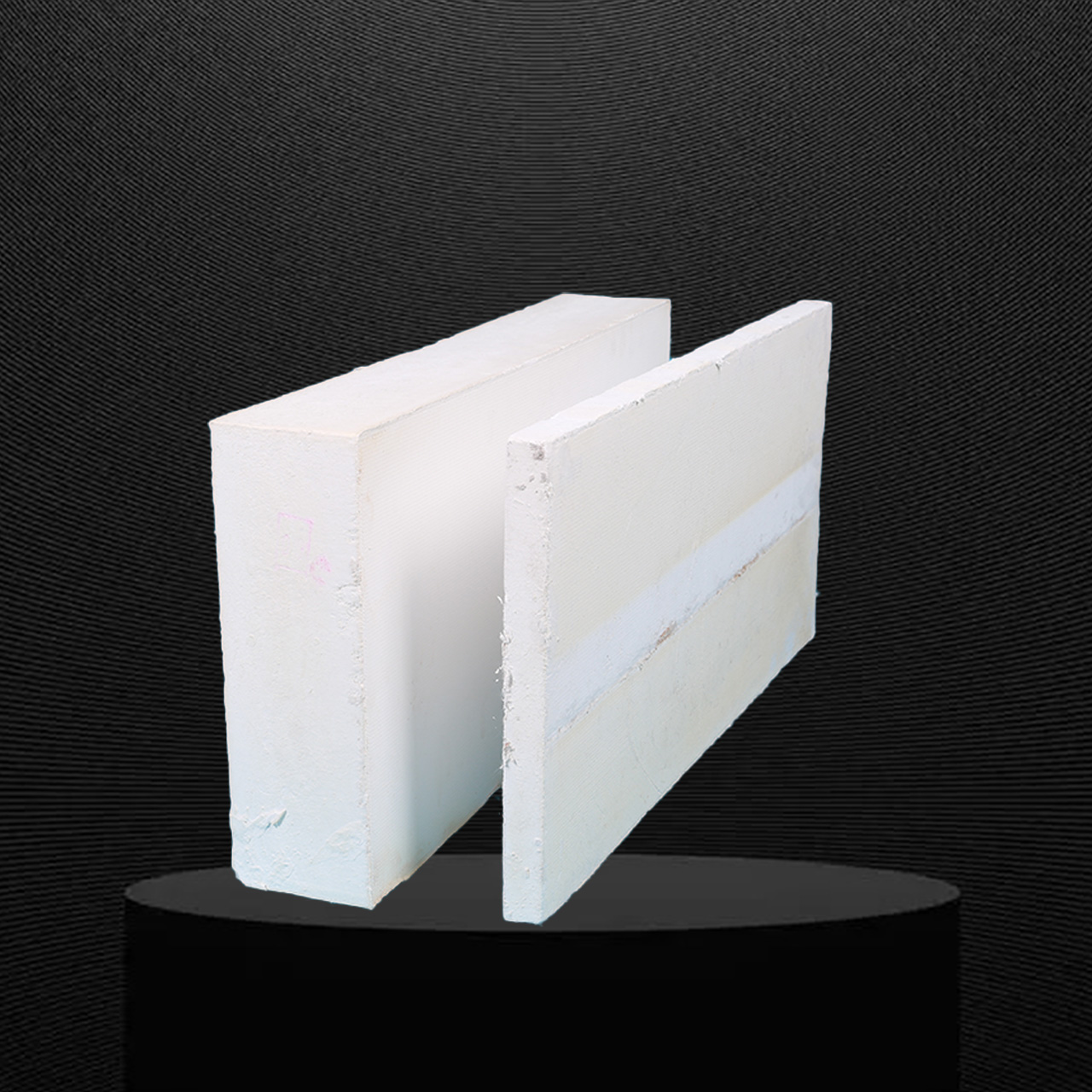

Developed by ROSEWOOL Company, this new technology enhances the quality of

ceramic fiber blankets in multiple ways. Firstly, the thermal insulation properties of the ceramic fiber blankets have been greatly optimized. Through innovative fiber - forming techniques and advanced manufacturing processes, the new blankets can better resist heat transfer, reducing energy loss in various industrial applications. This is especially crucial for industries such as steelmaking, glass production, and petrochemicals, where high - temperature environments are common.

Secondly, the mechanical strength of the ceramic fiber blankets has been enhanced. The new technology enables the production of blankets with a more uniform fiber structure, making them more resistant to tearing and abrasion. This not only extends the service life of the products but also reduces the need for frequent replacements, thus saving costs for businesses.

In addition, the new ceramic fiber blanket technology also focuses on environmental friendliness. The manufacturing process has been refined to reduce emissions and waste, making it more sustainable. This is in line with the global trend towards greener industrial development.

The applications of these new - generation ceramic fiber blankets are extensive. They can be used in high - temperature furnaces, kilns, and insulation pipelines. Moreover, in the field of building energy - conservation, they can be used as excellent insulation materials for buildings in extreme climates, helping to reduce heating and cooling costs.

Industry experts believe that this new technology will bring a new wave of innovation to the ceramic fiber blanket market. With its superior performance and environmental advantages, it is expected to gradually replace traditional insulation materials in many applications, opening up new opportunities for industries that rely on high - quality insulation products.