Calcium silicate pipe insulation is a rigid, fire-resistant thermal insulation material specifically designed to wrap pipes, ducts, and other cylindrical surfaces. It’s engineered from a blend of calcium silicate (a compound formed from calcium oxide and silica), reinforcing fibers (often cellulose, mineral wool, or synthetic fibers), and binders. This combination creates a dense, durable material that excels in high-temperature environments while maintaining structural integrity.

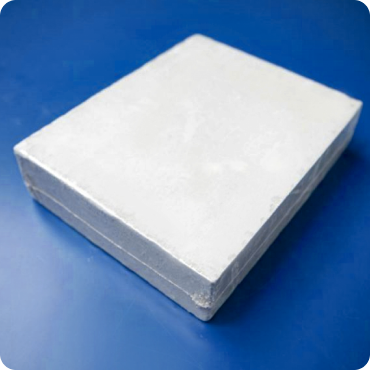

Unlike foam-based or fibrous insulation (e.g., fiberglass or polystyrene), calcium silicate is non-combustible and offers superior resistance to moisture, chemicals, and thermal drift (loss of insulation performance over time). It’s typically preformed into cylindrical sections, sleeves, or boards, making it easy to install around pipes of varying diameters.

To understand its functionality, let’s explore its core components:

What sets calcium silicate apart from other insulation materials? Here are its defining features:

Calcium silicate can withstand continuous operating temperatures up to 650°C (1,200°F) and short-term exposure up to 1,000°C (1,832°F). This makes it ideal for high-heat applications like steam pipes, boiler lines, and industrial process heating systems.

With a thermal conductivity (k-value) as low as 0.045–0.065 W/(m·K) at 100°C, it minimizes heat loss or gain. For example, insulating a 50mm-diameter steam pipe with calcium silicate can reduce heat loss by 70–80% compared to uninsulated pipes, lowering energy costs significantly.

Classified as A1 non-combustible under EN 13501-1 (the European standard for fire classification), it doesn’t burn or contribute to flame spread. This is critical for fire-prone areas like power plants, chemical refineries, and HVAC systems.

Unlike foam or cellulose insulation, calcium silicate is inherently water-repellent (especially when treated with hydrophobic additives). It resists moisture absorption, preventing mold growth, pipe corrosion, and degradation—key issues in humid or wet environments (e.g., coastal facilities, underground pipelines).

With proper installation, calcium silicate insulation lasts 20–30 years (or longer), outperforming shorter-lived materials like foam (10–15 years) or fiberglass (15–20 years). Its durability reduces maintenance and replacement costs over time.

To determine if calcium silicate is the right choice, it’s helpful to compare it with common alternatives:

| Material | Max Temp | Fire Rating | Moisture Resistance | Longevity |

|---|---|---|---|---|

| Calcium Silicate | Up to 650°C | A1 Non-combustible | Excellent | 20–30+ years |

| Fiberglass | Up to 400°C | Class B (Combustible) | Poor (absorbs moisture) | 10–15 years |

| Foam (e.g., XPS/EPS) | Up to 75°C | Class B–C | Moderate (degrades with moisture) | 5–10 years |

| Mineral Wool | Up to 700°C | Class A1–A2 | Good (but less rigid) | 15–25 years |

As the table shows, calcium silicate balances high-temperature performance, fire safety, and moisture resistance better than most alternatives.

Given its robust properties, calcium silicate insulation is used across diverse industries:

Power plants, chemical refineries, and food processing facilities rely on high-temperature pipes to transport steam, heated fluids, or raw materials. Calcium silicate’s ability to handle extreme heat and resist corrosion makes it ideal for insulating boiler feedwater lines, steam mains, and process pipelines.

Heating, ventilation, and air conditioning systems use pipes to distribute hot/cold water or refrigerants. Calcium silicate insulates chilled water lines (preventing condensation and mold) and hot water heating pipes (reducing energy waste in residential, commercial, or institutional buildings).

Underground heating networks in cold climates (e.g., Scandinavia, Canada) require insulation that withstands groundwater exposure. Calcium silicate’s moisture resistance and space-efficient rigid form make it perfect for insulating pipes in dense urban areas.

Fire sprinklers, standpipes, and smoke exhaust ducts need insulation that doesn’t fail in extreme heat. Calcium silicate’s non-combustible nature ensures these systems remain operational during emergencies, complying with fire codes like NFPA 25.

While professional installation is recommended, here’s a quick overview of the process:

Calcium silicate pipe insulation is far more than just a “heat blocker”—it’s a critical component in energy-efficient, safe, and durable industrial and commercial systems. By combining high-temperature resilience, fire safety, and moisture resistance, it outperforms traditional insulation materials in demanding applications.