In the competitive landscape of high-temperature insulation materials, ceramic fiber modules have emerged as a game-changer for industries ranging from metallurgy to petrochemicals. As global demand for energy-efficient, durable insulation solutions grows, one Chinese manufacturer stands out: Rosewool—a trusted name in precision-engineered ceramic fiber modules, combining cutting-edge technology with unmatched manufacturing expertise. In this article, we explore why Rosewool has become the go-to choice for businesses worldwide seeking reliable, cost-effective ceramic fiber module solutions.

Founded with a vision to revolutionize thermal insulation in heavy industries, Rosewool has evolved into one of China’s leading producers of ceramic fiber modules. With over [23] years of experience, state-of-the-art production facilities, and a team of R&D experts, Rosewool specializes in designing and manufacturing premium-quality modules that meet international standards (ISO 9001, ISO 14001, and more). Headquartered in [City, China], the company serves clients across Europe, North America, Southeast Asia, and beyond, delivering tailored solutions that address unique industrial challenges.

In a crowded market, Rosewool differentiates itself through a blend of innovation, quality, and customer-centric service. Here’s what sets it apart:

Rosewool’s production lines integrate automated cutting, shaping, and pressing equipment, ensuring precision and consistency in every module. Unlike traditional manufacturers relying on manual processes, Rosewool uses high-temperature sintering technology to enhance fiber density and thermal stability, resulting in modules that withstand extreme temperatures (up to 1600°C) without degradation.

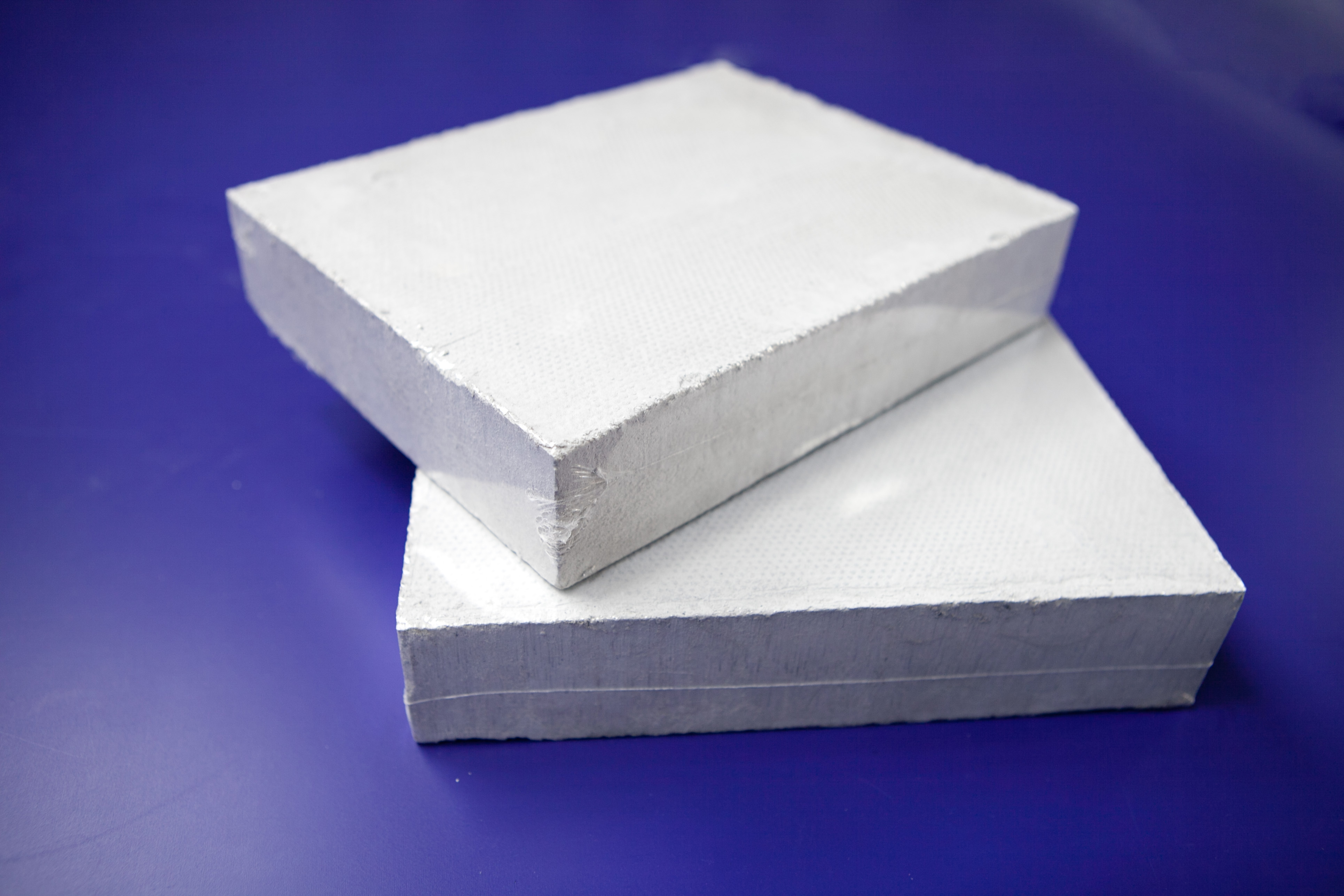

Understanding that no two industrial setups are identical, Rosewool offers fully customizable ceramic fiber modules. Whether clients need specific dimensions, shapes (e.g., curved panels, rectangular blocks), or material compositions (alumina-silica, zirconia-enhanced blends), Rosewool’s R&D team works closely to deliver prototypes and mass-produce solutions that fit seamlessly into their systems.

Quality is non-negotiable at Rosewool. Every batch of modules undergoes rigorous testing, including:

As a Chinese manufacturer, Rosewool leverages efficient supply chains and economies of scale to offer high-quality modules at competitive prices. Compared to European or North American brands, Rosewool delivers 20–30% cost savings while maintaining equivalent (or superior) performance metrics. This affordability makes it an ideal choice for budget-conscious industries upgrading from traditional refractory materials like bricks or castables.

Rosewool’s modules are engineered to excel in the harshest industrial environments. Their primary applications include:

From aluminum melting furnaces to ceramic firing kilns, Rosewool modules line walls, ceilings, and hearths to minimize heat loss, reduce fuel consumption by up to 30%, and extend furnace lifespan by protecting structural components from thermal stress.

In reactors, heat exchangers, and pipelines carrying high-temperature fluids (e.g., oil, gas), Rosewool modules provide reliable insulation, preventing energy waste and reducing emissions—critical for meeting global sustainability goals.

Used in ladle linings, rolling mill insulation, and annealing furnaces, Rosewool’s zirconia-enhanced modules withstand extreme mechanical stress and thermal cycling, ensuring consistent product quality in steel production.

In steam boilers, chimneys, and incinerators, Rosewool modules improve thermal efficiency, reduce maintenance costs, and lower the risk of fire hazards in high-temperature zones.

While China boasts many ceramic fiber module producers, Rosewool leads the pack due to:

Whether you’re a small-scale workshop or a multinational corporation, Rosewool simplifies the procurement process:

In an era where energy efficiency and industrial reliability are non-negotiable, Rosewool emerges as China’s premier manufacturer of ceramic fiber modules—combining cutting-edge technology, customizable solutions, and competitive pricing. Whether you need modules for a steel furnace, petrochemical reactor, or power plant, Rosewool delivers the performance, durability, and value that global industries trust.