Glass fiber boards are celebrated for their durability, fire resistance, and thermal efficiency, making them a staple in modern construction. But how long can you expect these materials to perform? The answer depends on multiple factors, including environmental conditions, installation quality, and maintenance practices. This guide explores the lifespan of glass fiber boards, offers tips to maximize longevity, and addresses FAQs to empower informed decisions.

1. Average Lifespan of Glass Fiber Boards

Under ideal conditions, high-quality glass fiber boards can last 30–50 years or more. However, real-world performance varies based on:

- Environment: Indoors, in dry climates, boards may exceed 50 years. Outdoors or in humid/corrosive settings, lifespan drops to 20–30 years.

- Material Quality: Premium boards with reinforced binders and additives (e.g., silicone) resist degradation better than budget options.

- Installation: Proper sealing and vapor barriers prevent moisture intrusion, a primary cause of premature aging.

2. Key Factors Affecting Longevity

A. Environmental Exposure

- UV Rays: Direct sunlight weakens board surfaces over time. Use UV-resistant coatings for exterior applications.

- Moisture: Humidity, rain, or condensation can lead to swelling, mold, or delamination. Install vapor barriers in high-humidity zones.

- Chemicals: Acidic fumes (e.g., near factories) or saltwater accelerate corrosion. Opt for chemically resistant coatings in such areas.

B. Physical Stress

- Impact Damage: Hail, tools, or foot traffic can crack boards. Protect with cladding or impact-resistant finishes.

- Thermal Cycling: Repeated expansion/contraction in extreme climates may cause warping. Choose flexible boards for temperature-fluctuating regions.

C. Installation Quality

- Sealing Gaps: Unsealed joints allow moisture penetration. Use foil tape or acrylic sealants.

- Fastener Spacing: Over-spaced screws lead to sagging. Follow manufacturer guidelines (e.g., 12–16 inches apart).

- Substrate Preparation: Uneven or damp substrates compromise adhesion. Ensure surfaces are clean, dry, and level.

3. How to Extend Glass Fiber Board Lifespan

Proactive Maintenance

- Annual Inspections: Check for cracks, loose boards, or water stains. Repair issues immediately.

- Cleaning: Use a soft brush and mild detergent to remove dirt. Avoid abrasive tools that damage surfaces.

- Coating Renewal: Reapply UV-resistant or waterproof coatings every 5–10 years.

Design Upgrades

- Cladding: Install metal, vinyl, or fiber cement siding over boards for added protection.

- Drainage Systems: Ensure proper roof/wall drainage to prevent water pooling.

- Fireproofing: Apply intumescent paints to enhance fire resistance (boards are already Class A fire-rated).

4. When to Replace Glass Fiber Boards

Replace boards if you observe:

- Structural Damage: Cracks wider than 1/8 inch, delamination, or sagging exceeding 1 inch.

- Water Infiltration: Persistent moisture leads to mold growth or rot.

- Energy Bill Spikes: Degraded insulation reduces R-value, increasing heating/cooling costs.

5. FAQs for SEO Optimization

Q: Do glass fiber boards decay over time?

A: Not inherently, but moisture, UV rays, or chemicals can cause gradual degradation. Regular inspections and coatings help prevent this.

Q: Can I extend the lifespan of outdoor glass fiber boards?

A: Yes. Use UV-resistant coatings, install rain screens, and avoid direct soil contact to prevent moisture wicking.

Q: Are glass fiber boards eco-friendly?

A: They’re recyclable and have a low carbon footprint compared to foam insulations. Check for GreenGuard or Cradle-to-Cradle certifications.

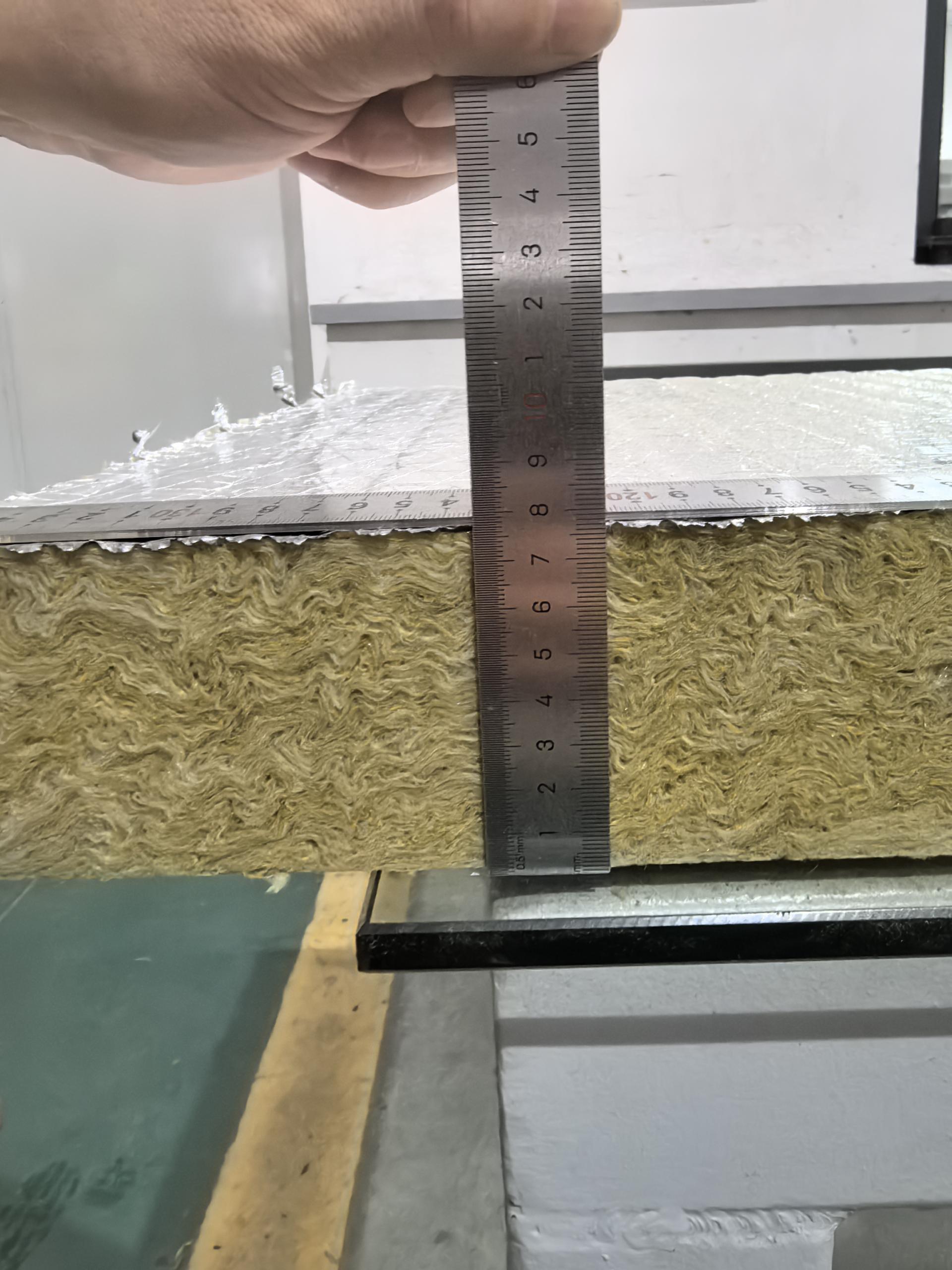

Q: How does thickness impact lifespan?

A: Thicker boards (≥50mm) resist physical stress better but require proper fastening to prevent sagging.

Conclusion

Glass fiber boards offer decades of reliable performance when installed and maintained correctly. By prioritizing quality materials, meticulous installation, and proactive care, you can maximize their lifespan while reducing long-term costs.