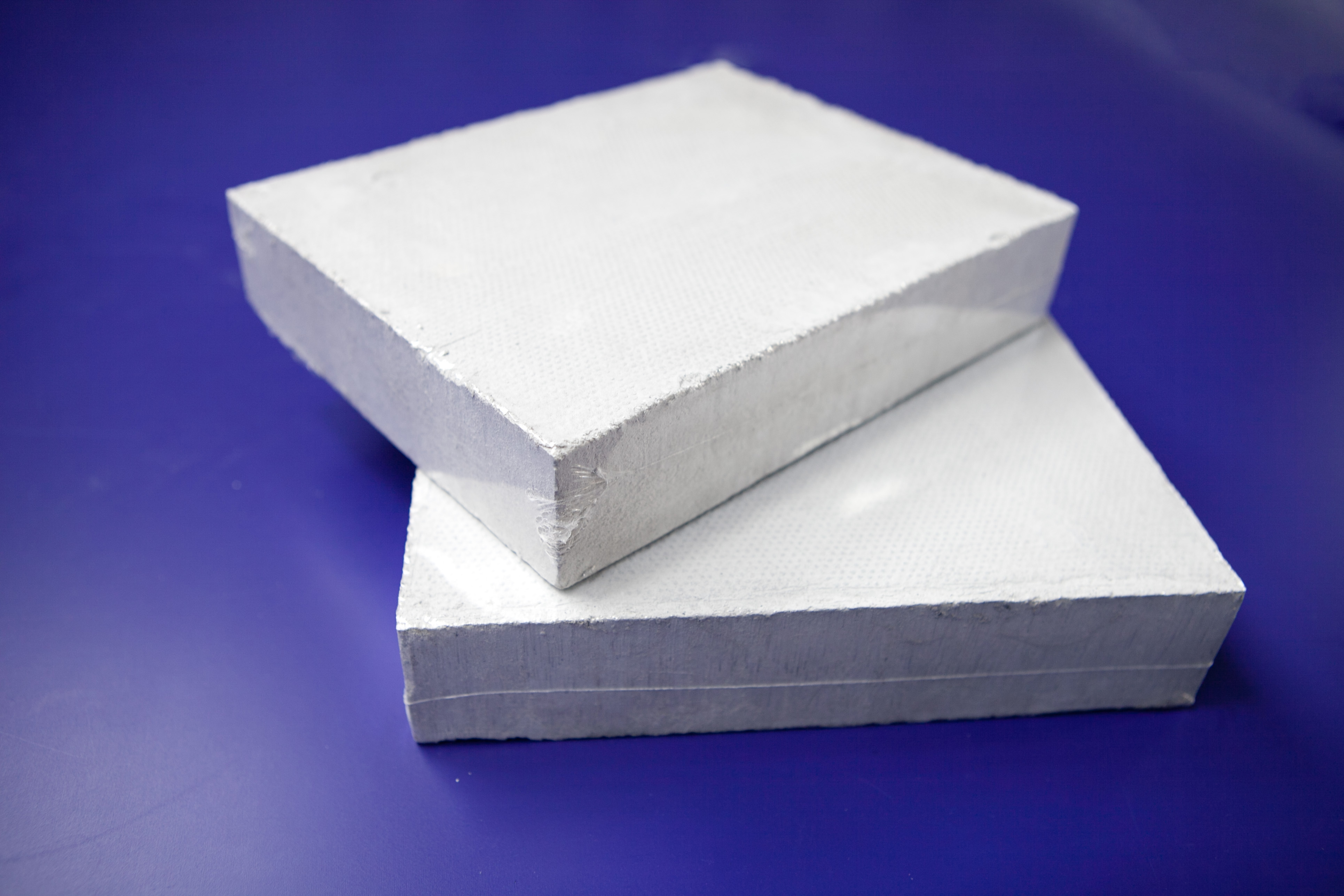

Rock wool insulation blankets are renowned for their thermal efficiency, fire resistance, and acoustic properties. When combined with an aluminum foil facing, they become a powerhouse solution for demanding insulation applications. This article explores the advantages of using foil-faced rock wool blankets and why they’re a top choice for contractors and DIY enthusiasts alike.

Aluminum foil acts as a radiant barrier, reflecting up to 97% of radiant heat away from surfaces. In environments with extreme temperatures—such as roofs, attics, or industrial settings—this feature:

Pro Tip: For optimal results, install the foil side facing the air gap or open space (e.g., between roof rafters).

Rock wool is inherently hydrophobic, meaning it repels water. The aluminum foil layer adds an extra defense against:

Best Practice: Seal seams with foil tape to create a continuous vapor barrier.

Rock wool is non-combustible (A1 fire rating), and aluminum foil melts at 660°C (1,220°F) but doesn’t fuel flames. Together, they provide:

Safety Note: Avoid compressing the blanket, as this reduces its fire-resistant air pockets.

Foil-faced rock wool blankets resist:

Application Idea: Use in outdoor HVAC ducts or marine environments for lasting performance.

The combination of rock wool and aluminum foil suits diverse projects:

DIY Hack: Cut the blanket using a utility knife and straightedge, then wrap around pipes or ducts for instant thermal protection.

Q: Which side faces outward during installation?

A: The foil side should face the air gap to reflect radiant heat. The rock wool side adheres to the substrate.

Q: Can I use foil-faced rock wool for soundproofing?

A: Yes! The density of rock wool dampens noise, while foil adds a mass-loaded barrier for enhanced acoustic control.

Q: Is aluminum foil eco-friendly?

A: Rock wool is recyclable, and aluminum foil can be repurposed. Opt for brands with eco-certifications for sustainability.

Rock wool blankets with aluminum foil offer a winning blend of thermal efficiency, moisture resistance, and fire safety. Whether you’re insulating a residential attic or an industrial furnace, this duo delivers reliability and longevity.