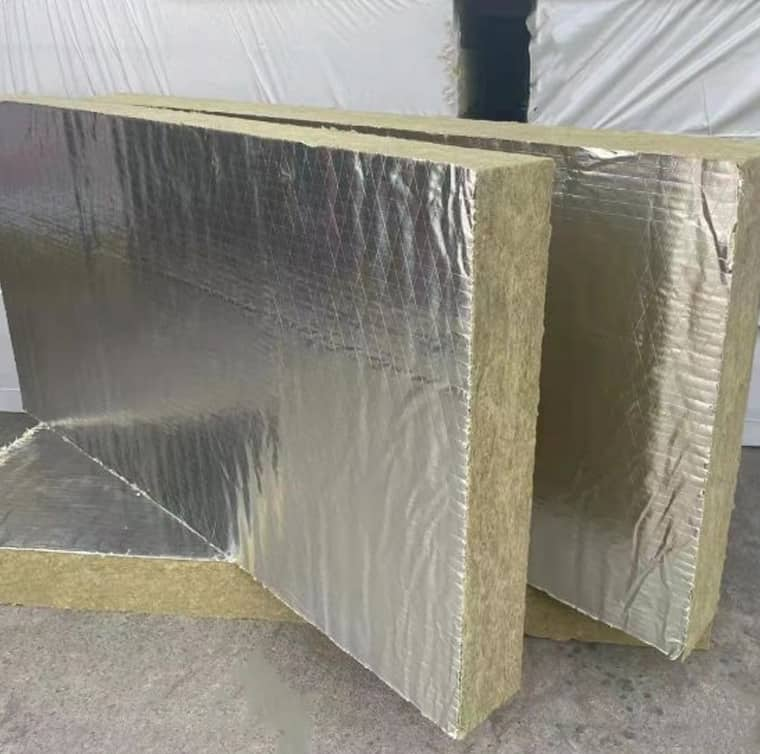

Rock wool board, also known as mineral wool insulation, is a versatile and high-performance material renowned for its exceptional fire resistance, thermal efficiency, and soundproofing capabilities. Unlike traditional insulation options, rock wool excels in demanding environments where safety, durability, and sustainability are critical.

1. Introduction: Why Rock Wool Board Stands Out

Rock wool is made from natural volcanic rock (basalt) and recycled slag, spun into fibers at extremely high temperatures. Its unique properties make it ideal for:

✅ Fire safety (non-combustible, slows flame spread)

✅ Thermal insulation (high R-value, energy efficiency)

✅ Sound absorption (reduces noise transfer)

✅ Moisture resistance (repels water, prevents mold)

Below are the most common and strategic uses for rock wool board.

2. Key Application Scenarios for Rock Wool Board

A. Fire-Rated Construction (Commercial & Residential)

- Fire barriers in commercial buildings:

- Rock wool’s Class A fire rating makes it a top choice for fire walls, partitions, and ceilings in offices, hotels, and retail spaces.

- Meets strict fire codes (e.g., ASTM E119, EN 13501-1).

- Residential fire protection:

- Used in garages, attics, and shared walls in multi-family homes to delay fire spread.

- Ideal for kitchen and utility room insulation where fire risks are higher.

B. High-Performance Soundproofing

- Recording studios & theaters:

- Rock wool’s dense fibers absorb low-frequency sounds (e.g., bass, machinery noise), making it perfect for acoustic treatment.

- Home theaters & entertainment rooms:

- Reduces echo and external noise for immersive audio experiences.

- Apartments & condominiums:

- Minimizes noise transfer between units, improving tenant comfort.

C. Industrial & HVAC Insulation

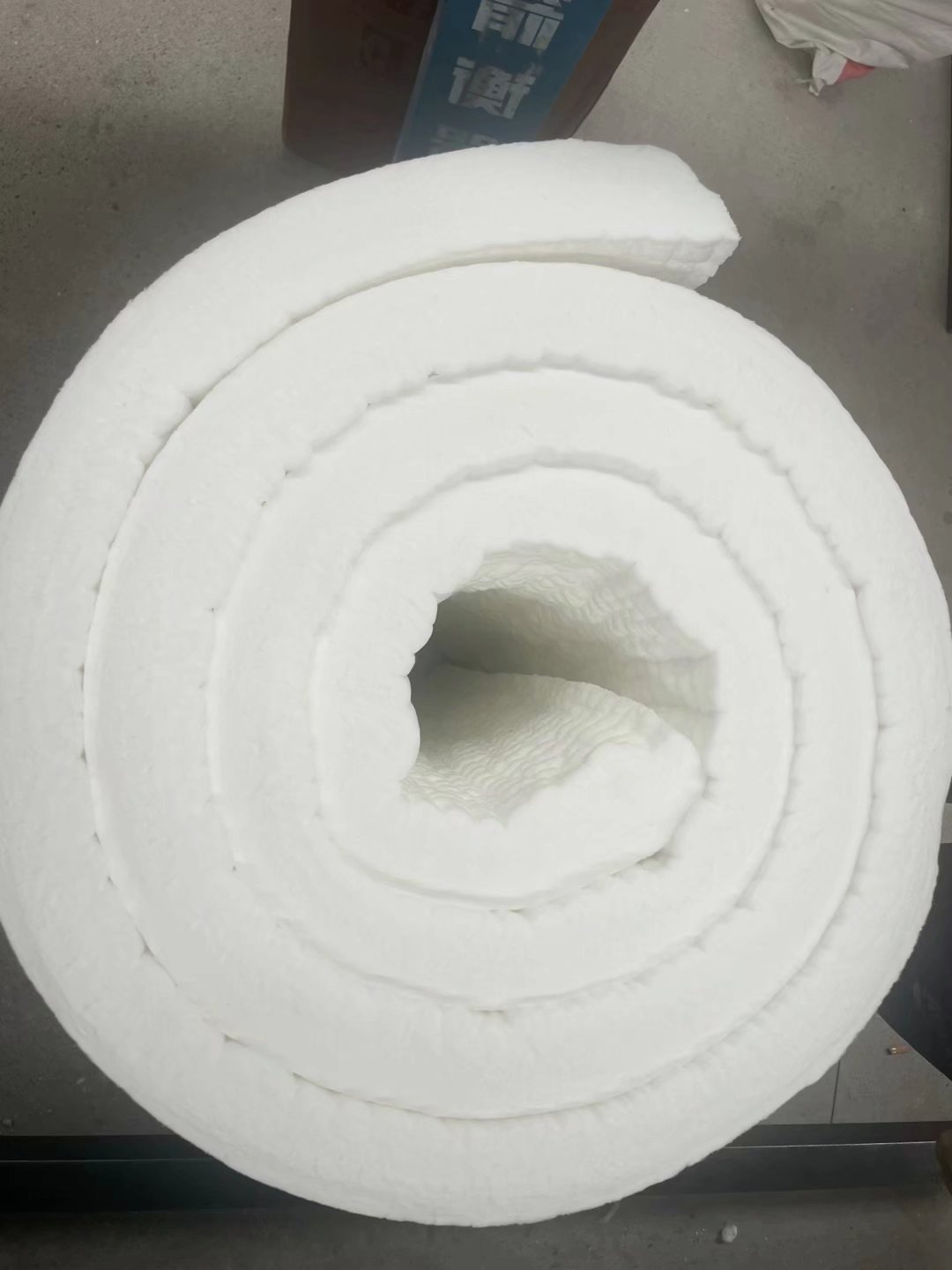

- Hot/cold pipe & duct insulation:

- Rock wool maintains thermal stability in extreme temperatures.

- Prevents energy loss in heating, ventilation, and air conditioning (HVAC) systems.

- Industrial machinery enclosures:

- Reduces noise and heat emissions from generators, compressors, and manufacturing equipment.

D. Marine & Offshore Applications

- Shipbuilding & offshore platforms:

- Rock wool’s water-repellent and corrosion-resistant properties make it ideal for marine environments.

- Withstands saltwater exposure, humidity, and vibration.

E. Exterior Wall & Roof Insulation

- Cold climate construction:

- Rock wool’s high R-value (3.3–4.3 per inch) keeps buildings warm in winter.

- Prevents thermal bridging when installed in exterior walls.

- Metal roofing insulation:

- Reduces condensation and improves energy efficiency in metal-roofed buildings.

F. Basement & Underfloor Insulation

- Damp & humid environments:

- Unlike fiberglass, rock wool repels moisture and does not promote mold growth.

- Ideal for basements, crawl spaces, and underfloor heating systems.

G. Sustainable & Green Building Projects

- LEED-certified constructions:

- Contributes to energy efficiency credits in green building certifications.

- Solar panel & geothermal system insulation:

- Enhances thermal performance in renewable energy installations.

3. Why Rock Wool Board Outperforms Alternatives in These Scenarios?

| Feature |

Rock Wool Board Advantage |

| Sound Absorption |

Superior for low-frequency noise (vs. fiberglass better for mid-high frequencies) |

| Moisture Control |

Hydrophobic, mold-resistant (vs. fiberglass absorbs moisture) |

| Durability |

Maintains R-value over time (vs. fiberglass may compress or degrade) |

4. Common Misconceptions About Rock Wool Board

❌ Myth 1: Rock wool is too expensive for residential use.

✔️ Reality: While pricier than fiberglass, its long-term energy savings and fire safety justify the cost.

❌ Myth 2: Rock wool installation is difficult.

✔️ Reality: Requires gloves and masks but is manageable for professionals (pre-cut panels simplify DIY).

❌ Myth 3: Rock wool causes health issues like asbestos.

✔️ Reality: Classified as non-carcinogenic by WHO/IARC; modern production minimizes irritation.

5. How to Choose the Right Rock Wool Board for Your Project?

- Density: Higher density (100–200 kg/m³) for fire/soundproofing; lower density (80–120 kg/m³) for general insulation.

- Board Type: Rigid boards for walls/ceilings; flexible mats for pipes/ducts.

- Certifications: Look for ASTM, EN, or UL fire ratings and eco-labels (e.g., GREENGUARD).

6. Case Studies: Real-World Applications

- London’s The Shard (Skyscraper): Uses rock wool for fire safety and acoustic comfort.

- Tesla Gigafactory (Renewable Energy): Insulates HVAC systems with rock wool for energy efficiency.

- Marine Vessels (Royal Navy): Relies on rock wool for fire and moisture protection in harsh conditions.

For standard residential insulation (e.g., attics, dry walls), fiberglass may suffice—but for high-performance demands, rock wool is unmatched.