When selecting insulation materials, rock wool board and glass wool board are two widely used options, but their differences in performance, safety, and application are often misunderstood. This guide compares their composition, thermal efficiency, fire resistance, soundproofing capabilities, and more to help you make an informed decision for your project.

Quick Comparison Chart

| Feature |

Rock Wool Board |

Glass Wool Board |

| Raw Materials |

Basalt rock |

Sintered glass |

| Thermal Conductivity |

≤0.044 W/m·K |

0.036 W/m·K |

| Sound Absorption |

4.5–5.0 NRC (high-density structure) |

4.0–4.5 NRC (lightweight fibers) |

| Durability |

Resists moisture, pests, and sagging |

May settle over time in humid conditions |

1. Material Composition & Manufacturing Process

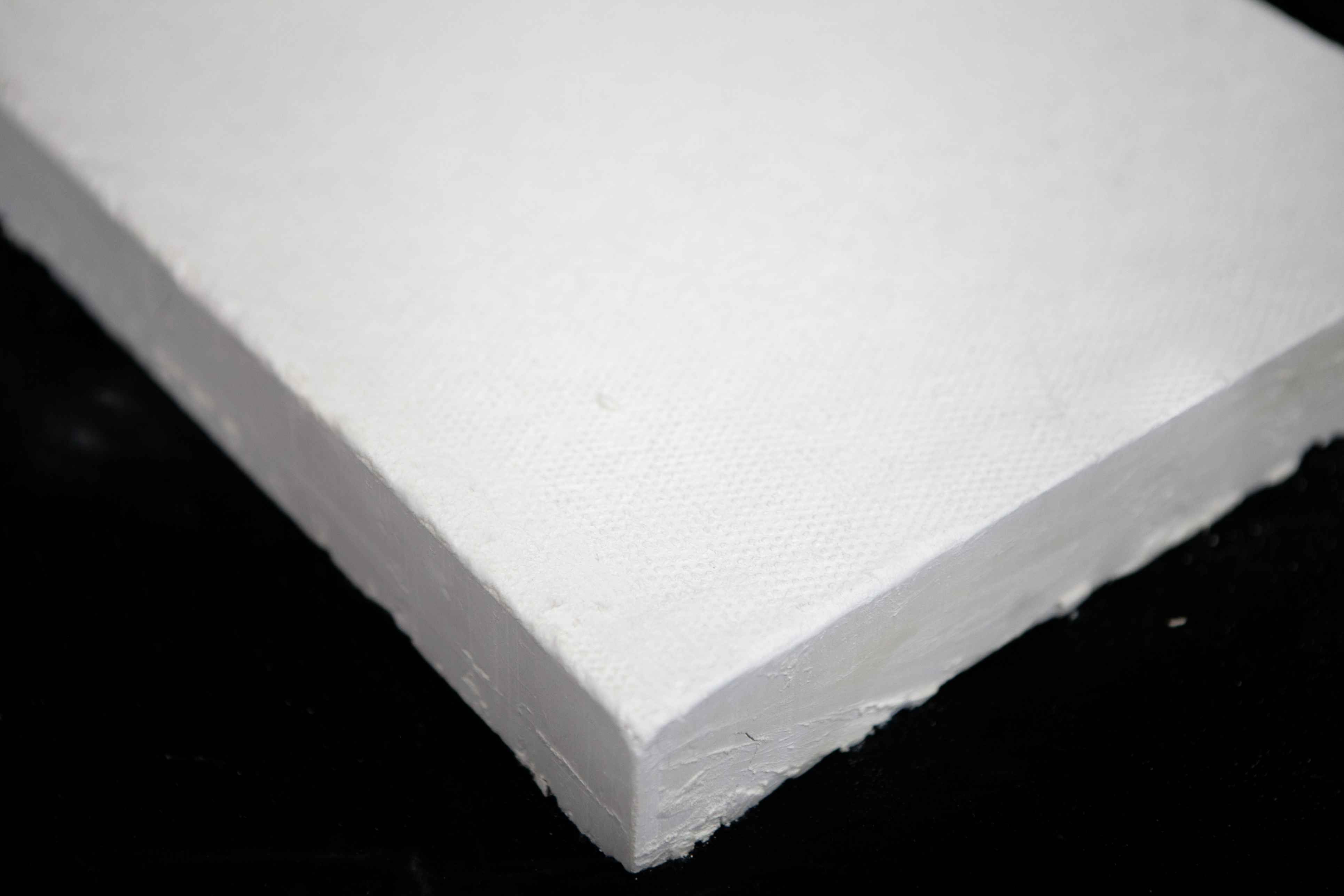

Rock Wool Board

- Raw Materials: Made of high-quality basalt and dolomite.

- Production: Melted at 1,500°C, spun into dense fibers, and compressed into rigid boards.

- Sustainability: Contains up to 75% recycled content; fully recyclable and non-toxic.

Glass Wool Board

- Raw Materials: Primarily glass (60–80%) mixed with silica sand.

- Production: Glass melted at 1,200°C, spun into fine fibers, and bonded with formaldehyde-based resins.

- Sustainability: High recycled content but may emit trace VOCs from resins.

Key Difference: Rock wool uses volcanic rock and slag, while glass wool relies on recycled glass.

2. Thermal Insulation Performance

Rock Wool Board

- Higher Density: 60-150 kg/m³, reducing heat transfer through conduction.

- R-Value: R-4.0–4.3 per inch, ideal for extreme temperatures.

- Moisture Resistance: Hydrophobic fibers repel water, preventing mold growth.

Glass Wool Board

- Lower Density: 12–48 kg/m³, making it lightweight but prone to settling.

- R-Value: R-3.0–3.8 per inch, suitable for moderate climates.

- Vulnerability: Absorbs moisture if unsealed, reducing insulation efficiency.

Best For:

- Rock wool: Roofs, basements, and high-humidity areas.

- Glass wool: Interior walls and attics in dry climates.

3. Fire Resistance & Safety

Rock Wool Board

- Non-Combustible: Withstands temperatures exceeding 1,000°C (compliant with ASTM E136).

- Fire Barrier: Used in firewalls, electrical rooms, and escape routes.

- Safety: Fibers are non-respirable and do not release toxic fumes.

Glass Wool Board

- Limited Fire Resistance: Melts at 500°C and may drip, spreading flames.

- Chemical Risks: Binders may emit formaldehyde during installation or fires.

Critical Note: Rock wool is mandatory in fire-rated constructions (e.g., commercial buildings).

4. Acoustic Insulation Capabilities

Rock Wool Board

- Superior Sound Dampening: High density blocks both airborne (e.g., traffic) and impact noise (e.g., footsteps).

- Applications: Recording studios, home theaters, and apartment partitions.

Glass Wool Board

- Moderate Noise Reduction: Effective for airborne noise but struggles with low-frequency sounds.

- Applications: Office partitions, HVAC duct wrapping.

Pro Tip: Layer rock wool with mass-loaded vinyl for maximum soundproofing.

5. Installation & Longevity

- Pros: Rigid boards are easy to cut (use a serrated knife) and fit tightly.

- Cons: Heavyweight requires two people for large panels.

- Pros: Lightweight and flexible; conforms to irregular spaces.

- Cons: Fibers shed during cutting; requires gloves, goggles, and masks.

Durability:

- Rock wool lasts 50+ years without sagging.

- Glass wool may compress over 20–30 years, reducing R-value.

6. Cost and Environmental Impact

| Factor |

Rock Wool Board |

Glass Wool Board |

| Material Cost |

Higher ($$) |

Lower ($) |

| Lifespan |

50+ years |

20–30 years |

| Recyclability |

Fully recyclable |

Recyclable but resin contamination risks |

| Carbon Footprint |

Lower (uses industrial byproducts) |

Higher (energy-intensive glass melting) |

Budget Tip: Glass wool is cheaper upfront, but rock wool’s longevity offsets costs over time.

Which Should You Choose? Decision Guide

✅ Choose Rock Wool Board If:

- Fire safety is critical (e.g., garages, industrial settings).

- You need moisture-resistant insulation for basements or roofs.

- Superior soundproofing is a priority.

✅ Choose Glass Wool Board If:

- You’re insulating dry, low-risk areas (e.g., interior walls).

- Budget constraints are significant.

- Lightweight materials are needed for DIY projects.

FAQs

❓ Is glass wool the same as fiberglass?

Yes. “Glass wool” refers to fiberglass insulation in board or batt form.

❓ Can glass wool cause health issues?

Improper handling may release airborne fibers, irritating skin and lungs. Always use PPE during installation.

❓ Does rock wool require a vapor barrier?

Not necessarily—its moisture-resistant properties often eliminate the need.

❓ Which is better for soundproofing floors?

Rock wool’s density makes it ideal for impact noise reduction between floors.