In the world of insulation, choosing the right material can significantly impact energy efficiency, safety, and overall performance. Among the various options available, ceramic fiber blankets stand out as a popular choice for high-temperature applications. However, understanding how they compare to other insulation materials is crucial for making an informed decision. This article will delve into the key differences between ceramic fiber blankets and common alternatives such as fiberglass, rock wool, and polyurethane foam.

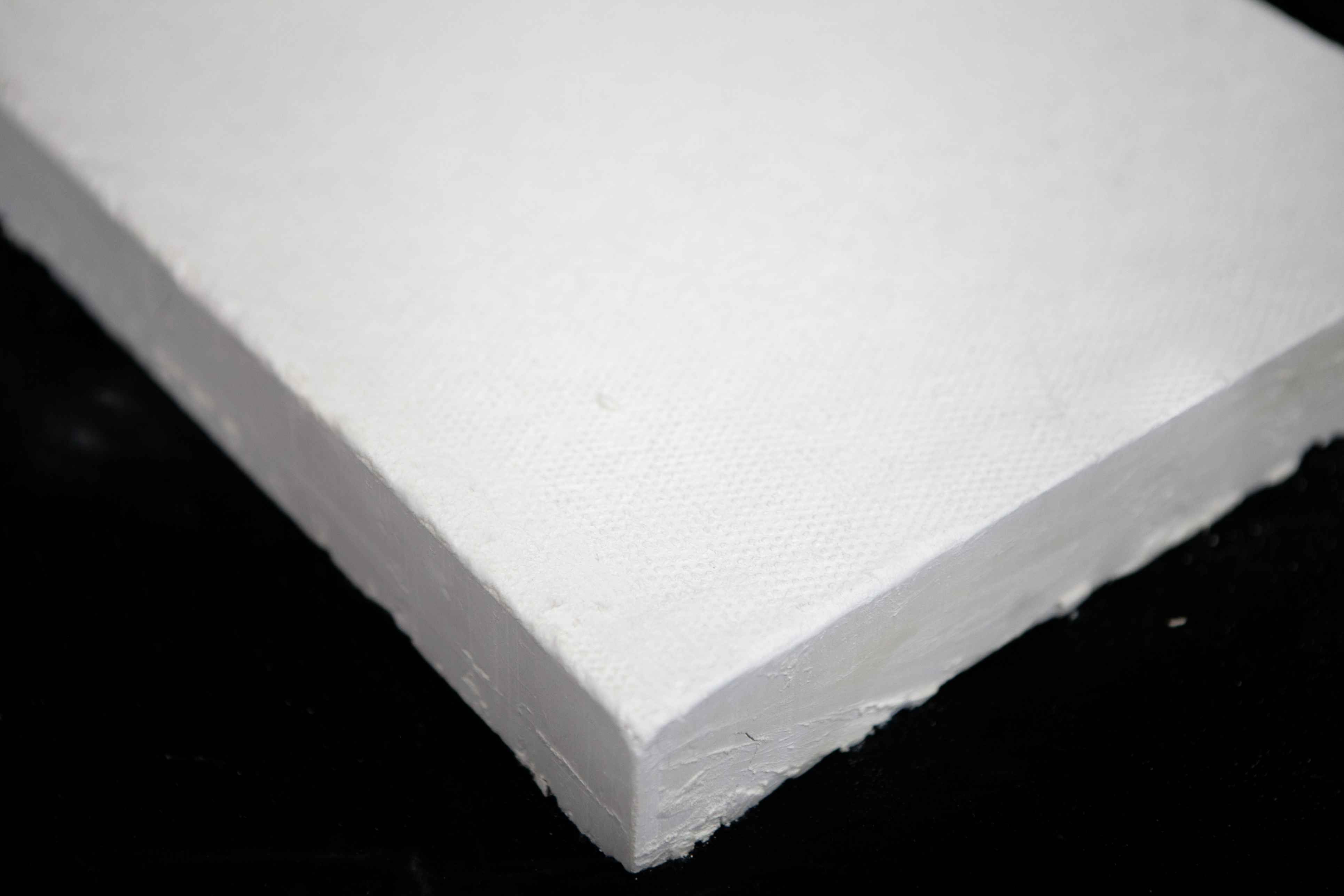

Ceramic Fiber Blankets: An Overview

Ceramic fiber blankets are primarily composed of aluminum silicate fibers, which are formed by melting raw materials at extremely high temperatures and then spun into a flexible, lightweight matrix. These blankets are renowned for their exceptional heat resistance, low thermal conductivity, and excellent insulation properties, making them ideal for use in environments where temperatures can reach up to 1400°C (2552°F).

Advantages of Ceramic Fiber Blankets

- High-Temperature Resistance: Ceramic fiber blankets can withstand intense heat without melting, burning, or releasing toxic fumes, making them a top choice for industrial furnaces, kilns, and fireproofing applications.

- Low Thermal Conductivity: With a thermal conductivity rate typically ranging from 0.03 - 0.045 W/(m·K), these blankets effectively reduce heat transfer, enhancing energy efficiency.

- Lightweight and Flexible: Their lightweight nature and flexibility make ceramic fiber blankets easy to handle, cut, and install in various shapes and sizes.

- Chemical Stability: They are resistant to most chemicals, ensuring long-term durability in harsh environments.

Disadvantages of Ceramic Fiber Blankets

- Moisture Sensitivity: Ceramic fiber blankets are highly absorbent and can lose their insulation properties when exposed to water, limiting their use in humid or wet environments.

- Higher Cost: Compared to some other insulation materials, ceramic fiber blankets can be more expensive, especially for large-scale projects.

Fiberglass Insulation

Fiberglass insulation is one of the most commonly used insulation materials, made from extremely fine glass fibers. It is available in various forms, including batts, rolls, and loose-fill.

Advantages of Fiberglass Insulation

- Cost-Effective: Fiberglass is relatively inexpensive, making it a budget-friendly option for many residential and commercial insulation projects.

- Good Thermal and Acoustic Insulation: It provides decent thermal insulation and soundproofing, suitable for walls, attics, and ceilings in buildings.

- Wide Availability: Fiberglass insulation is readily available in most hardware stores, making it easily accessible for DIY projects.

Disadvantages of Fiberglass Insulation

- Limited Temperature Resistance: Fiberglass has a lower heat resistance compared to ceramic fiber blankets and may degrade or release harmful substances at high temperatures.

- Irritation Risk: The fine glass fibers can cause skin, eye, and respiratory irritation during installation, requiring proper protective gear.

- Moisture Absorption: Similar to ceramic fiber blankets, fiberglass can absorb moisture, reducing its insulation effectiveness over time.

Rock Wool Insulation

Rock wool, also known as mineral wool, is made from molten rock, typically basalt, which is spun into fibers. It is widely used for both thermal and acoustic insulation.

Advantages of Rock Wool Insulation

- High Fire Resistance: Rock wool is non-combustible and has excellent fireproofing properties, meeting strict safety standards.

- Good Thermal and Acoustic Performance: It offers efficient thermal insulation and sound absorption, making it suitable for industrial, commercial, and residential applications.

- Moisture Resistance: Unlike ceramic fiber and fiberglass, rock wool is highly resistant to moisture, maintaining its insulation performance even in damp environments.

Disadvantages of Rock Wool Insulation

- Heavyweight: Rock wool insulation is denser and heavier than ceramic fiber blankets, which can make installation more challenging, especially in overhead applications.

- Higher Installation Cost: Due to its weight and the need for specialized installation techniques, the overall cost of installing rock wool insulation can be higher.

Polyurethane Foam Insulation

Polyurethane foam is a synthetic insulation material available in two main types: open-cell and closed-cell. It is applied as a spray or in rigid board form.

Advantages of Polyurethane Foam Insulation

- High R-Value: Polyurethane foam has a high thermal resistance (R-value), providing excellent insulation with relatively thin layers.

- Air Sealing Properties: It effectively seals gaps and cracks, preventing air leakage and improving energy efficiency in buildings.

- Versatile Application: Can be used in a variety of applications, including walls, roofs, floors, and even in refrigeration and cold storage.

Disadvantages of Polyurethane Foam Insulation

- Flammability: Polyurethane foam is combustible and may release toxic fumes when burned, requiring additional fire-retardant treatments.

- Environmental Concerns: The production of polyurethane foam involves the use of chemicals that can have a negative impact on the environment.

- Higher Cost: It is generally more expensive than fiberglass and rock wool insulation, especially for large-scale projects.

Which Material is Right for You?

The choice between ceramic fiber blankets and other insulation materials depends on several factors, including the application, temperature requirements, budget, and environmental conditions. Here's a quick summary to help you decide:

- High-Temperature Applications: For industrial furnaces, kilns, or areas exposed to extreme heat, ceramic fiber blankets are the best choice due to their superior heat resistance.

- Residential and Commercial Buildings: Fiberglass and rock wool are popular options for general building insulation, offering a balance of cost, performance, and availability. Polyurethane foam is ideal for applications where air sealing and high R-value are priorities.

- Moisture-Prone Environments: Rock wool insulation is the most suitable option as it can withstand moisture without losing its effectiveness.

In conclusion, each insulation material has its own unique set of advantages and disadvantages. By understanding these differences and considering your specific needs, you can select the insulation material that best fits your project requirements, ensuring optimal performance and energy efficiency.