Introduction

Ceramic fiber blankets are renowned for their ability to withstand scorching temperatures up to 1,430°C (2,600°F), making them indispensable in furnaces, kilns, and aerospace applications. But when it comes to water resistance, these materials face a critical weakness. This article answers the question, “Is the ceramic fiber blanket waterproof?”, explains why moisture damages these heat-resistant marvels, and provides actionable solutions to protect your insulation investment.

The Short Answer: No, Ceramic Fiber Blankets Are Not Waterproof

Ceramic fiber blankets, made from aluminosilicate fibers, are inherently hydrophilic (water-attracting). Unlike hydrophobic materials like rock wool, they absorb moisture readily, leading to structural degradation and performance loss. Here’s why:

1. Chemical Hydrolysis: Water Breaks Molecular Bonds

- Science: Water molecules react with the silica-alumina bonds (Si-O-Al) in ceramic fibers, causing hydrolysis. This dissolves the amorphous fiber structure into colloidal silica.

- Data: Per ASTM C1134, water immersion for 24 hours can reduce tensile strength by 30–50%.

2. High Water Absorption Rate

- Porosity: Ceramic fiber blankets have a porous structure (up to 90% void space), allowing rapid moisture penetration.

- Absorption Capacity: They can absorb 15–20% of their weight in water, increasing thermal conductivity and reducing insulation efficiency.

3 Critical Risks of Water Exposure

| Risk |

Impact |

| Structural Weakness |

Fibers become brittle, leading to crumbling during installation/use. |

| Thermal Inefficiency |

Wet blankets lose insulation capacity, raising energy costs by 10–25%. |

| Health Hazards |

Wet fibers release respirable particles, exceeding OSHA’s 0.1 fiber/cm³ limit. |

How to Waterproof Ceramic Fiber Blankets: 4 Practical Solutions

1. Apply Water-Repellent Coatings

- Options:

- Silicone Sprays: Create a hydrophobic layer without blocking heat resistance (max 1,000°C).

- Aluminum Foil Lamination: Foil-backed blankets (e.g., Fiberfrax Duraboard®) block moisture and reflect radiant heat.

- Limitation: Coatings may reduce maximum service temperature by 50–100°C.

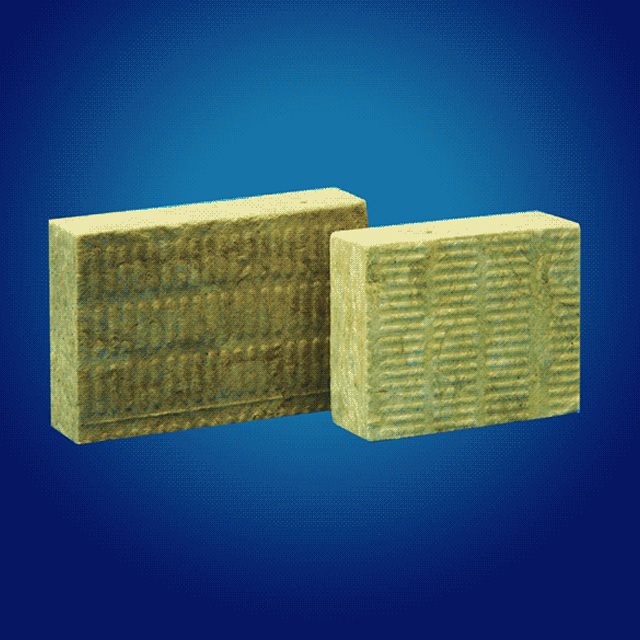

2. Use Alternative Moisture-Resistant Materials

- Polycrystalline Wool (PCW): Higher density and lower porosity minimize water absorption (5–8% by weight).

- Calcium Silicate Boards: Ideal for humid environments like boilers or outdoor installations.

3. Proper Installation Techniques

- Seal Joints: Use high-temperature sealants (e.g., Rutland 77) to prevent water ingress at overlaps.

- Add Protective Layers: Install metal cladding or waterproof membranes over insulation in exposed areas.

4. Control Storage Conditions

- Humidity: Store in dry environments (<60% RH) on pallets to avoid ground moisture.

- Temperature: Avoid condensation by keeping storage areas above 10°C (50°F).

FAQs: Ceramic Fiber Blankets & Waterproofing

Q: Can ceramic fiber blankets be used outdoors?

A: Only if shielded with waterproof cladding (e.g., stainless steel jackets) or coated with silicone. Never expose them directly to rain.

Q: What happens if a ceramic fiber blanket gets wet?

A: Dry it slowly at <100°C to restore partial insulation. However, hydrolyzed fibers will remain brittle—replace if strength drops below 50% (test via ASTM C1335).

Q: How to test waterproofing effectiveness?

A: Conduct water immersion tests (ASTM C1134) and measure post-drying tensile strength (ASTM C1335).