In the realm of industrial heat management,

Ceramic Fiber Board stands out as a premier material for insulation applications. This article delves into the significance, benefits, and applications of Ceramic Fiber Boards in heat insulation, tailored to enhance your knowledge and guide your material selection process.

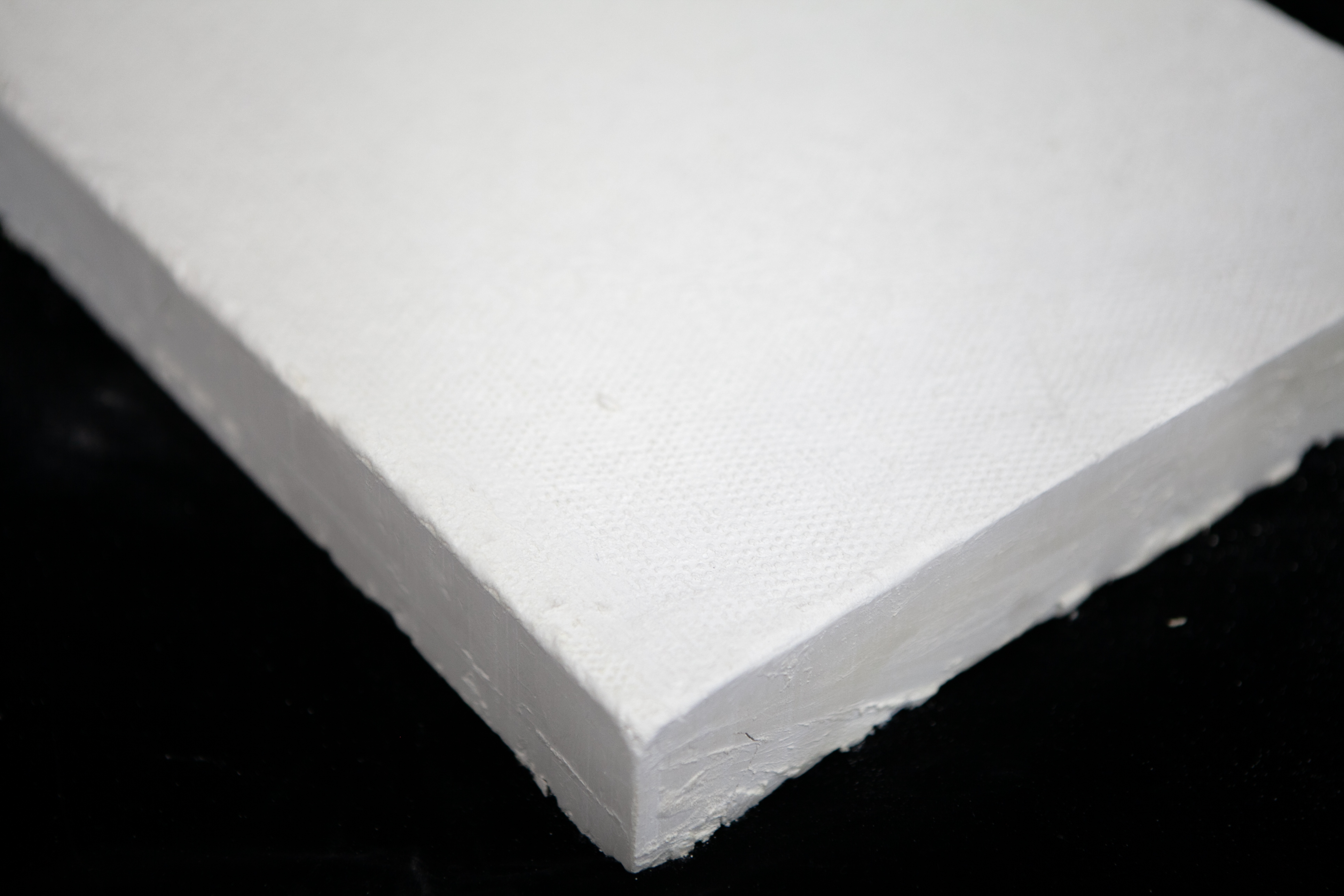

Understanding Ceramic Fiber Board

Ceramic Fiber Boards are lightweight, high-temperature resistant boards made from ceramic fibers. These boards are engineered to provide exceptional thermal insulation across a wide range of temperatures, typically from 1000°C to 1600°C, depending on the specific grade. Their unique properties make them indispensable in various industrial sectors where heat management is crucial.

Key Benefits of Ceramic Fiber Board in Heat Insulation

- Superior Insulation Properties: Ceramic Fiber Boards offer low thermal conductivity, which means they effectively resist heat flow. This property is vital for maintaining temperature control in industrial furnaces, kilns, and reactors.

- Lightweight and Easy to Install: Compared to traditional insulation materials like brick or concrete, Ceramic Fiber Boards are much lighter, making them easier to handle and install. This not only speeds up the installation process but also reduces the structural load on buildings.

- High-Temperature Resistance: These boards can withstand extremely high temperatures without degrading, making them suitable for applications in environments where other materials would fail.

- Energy Efficiency: By significantly reducing heat loss, Ceramic Fiber Boards contribute to energy savings, which is economically beneficial and environmentally friendly.

- Long Service Life: The durability of Ceramic Fiber Boards ensures a long service life with minimal maintenance, reducing downtime and replacement costs.

- Flexibility and Customization: Ceramic Fiber Boards can be manufactured in various densities, sizes, and shapes, allowing for customization to fit specific insulation requirements.

Applications of Ceramic Fiber Board in Heat Insulation

- Industrial Furnaces: Used as a lining material in furnaces to reduce heat loss and protect the furnace structure from high temperatures.

- Kilns: Employed in kilns for ceramic and glass manufacturing to maintain consistent temperatures and improve energy efficiency.

- Boilers Insulation: Utilized in boilers to prevent heat loss and protect external surfaces from high temperatures, ensuring safety and efficiency.

- Heat Exchangers: Installed in heat exchangers to minimize heat loss and maximize thermal efficiency.

- Chemical and Petrochemical Plants: Used in reactors and distillation columns where precise temperature control is essential for process efficiency and safety.

- Metallurgical Processes: Applied in metallurgical furnaces for insulation, contributing to energy savings and improved process control.

Conclusion

Ceramic Fiber Board is a game-changer in the field of heat insulation. Its superior insulation properties, combined with its high-temperature resistance and energy efficiency, make it an ideal choice for a wide range of industrial applications. By choosing Ceramic Fiber Boards for your insulation needs, you can achieve significant cost savings, enhance safety, and contribute to environmental sustainability.