Rosewool was founded in 1982 and is a leading Chinese ceramic fiberboard manufacturer headquartered in Zhengzhou, Henan Province, China. Rosewool specializes in the research and development, production, and export of advanced insulation solutions, and has now developed into one of the largest ceramic fiber product suppliers in Asia. The company focuses on innovation, compliance, and customer-centric services, providing services to customers in regions such as Europe, North America, the Middle East, and Southeast Asia.

Core Advantages of Rosewool Ceramic Fiber Boards

1. Unmatched Technical Expertise

Rosewool’s success stems from its investment in advanced manufacturing technology. The company operates state-of-the-art production facilities equipped with automated fiber-spinning lines, precision cutting machines, and high-temperature curing ovens. This ensures consistent product quality, tight dimensional tolerances, and minimal defects—critical for industrial applications where reliability is non-negotiable.

2. Diverse Product Portfolio

Rosewool offers a wide range of ceramic fiber boards tailored to diverse industrial needs:

- Standard Boards: Rated for 800–1200°C, ideal for boilers, furnaces, and HVAC systems.

- High-Purity Boards: Made with ≥96% alumina-silica fibers, withstand up to 1400°C, and resist corrosion in chemical processing.

- Custom Shapes & Sizes: From thin-gauge sheets (20mm) to large-format boards (3000mm x 2000mm), Rosewool accommodates custom orders for niche applications.

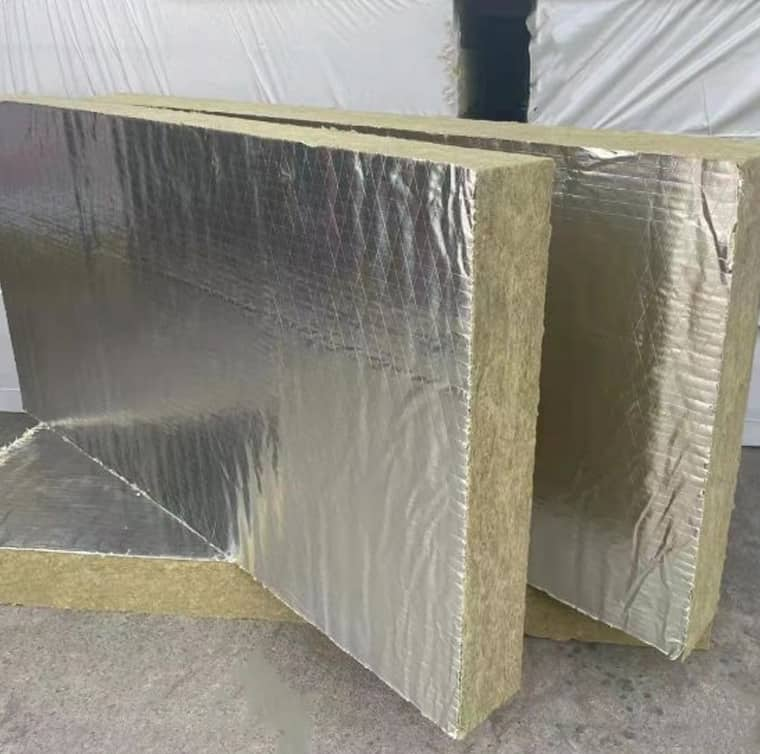

- Specialized Coatings: Aluminum foil-lined boards for moisture resistance, or low-chloride grades for marine environments.

3. Global Compliance & Certifications

Rosewool prioritizes quality and safety, holding certifications such as:

- ISO 9001:2015 (Quality Management System)

- ISO 14001:2015 (Environmental Management System)

- ASTM E136 (Non-Combustibility)

- CE Marking (EU Market Compliance)

- SGS Approved (Product Safety and Performance)

These certifications assure buyers that Rosewool products meet international standards for thermal efficiency, fire resistance, and environmental safety.

4. Competitive Pricing & Efficient Logistics

As a Chinese manufacturer, Rosewool leverages economies of scale to offer 20–40% lower prices compared to European or North American suppliers—without compromising quality.

Key Applications of Rosewool Ceramic Fiber Boards

Rosewool’s boards are trusted in some of the harshest industrial environments:

1. Power Generation

- Boiler Systems: Insulate steam pipes, economizers, and superheaters in coal, gas, or biomass-fired plants to reduce heat loss by 70–90%.

- HRSG (Heat Recovery Steam Generators): Line exhaust ducts to recover waste heat and boost turbine efficiency.

2. Oil & Gas & Chemical Processing

- Pipeline Insulation: Protect high-pressure pipes carrying hot crude oil (150–300°C) or natural gas in offshore rigs from thermal loss and corrosion.

- Reactor Vessels: Insulate lines with corrosive fluids (e.g., sulfuric acid, ammonia) while preventing CUI (Corrosion Under Insulation).

3. Metal Processing

- Annealing Ovens: Maintain consistent temperatures in heat-treatment chambers for steel and aluminum to ensure material integrity.

- Foundries: Line casting molds or ladles to retain molten metal temperatures and reduce energy use.

4. Renewable Energy

- Biomass Boilers: Insulate high-temp exhaust systems in bioenergy plants to improve combustion efficiency.

- Concentrated Solar Power (CSP): Line receiver tubes to retain thermal energy, boosting electricity output.

Why Choose Rosewool Over Other Chinese Manufacturers?

While China boasts many ceramic fiber board suppliers, Rosewool differentiates itself through:

1. Customer-Centric Service

- Free Samples: Buyers can request samples (1–2 sqm) to test thermal performance, thickness, and handling before bulk orders.

- Technical Support: Dedicated engineers provide thermal conductivity calculations, installation guides, and troubleshooting assistance.

2. Flexible Customization

Rosewool works closely with clients to develop tailored solutions, such as:

- Boards with specific thicknesses (20–150mm) or dimensions.

- Coatings for moisture resistance, UV protection, or chemical resistance.

- OEM packaging and labeling for global distribution.

FAQ: Common Questions About Rosewool Ceramic Fiber Boards

Q1: Are Rosewool boards suitable for high-temperature applications above 1200°C?

A: Yes—Rosewool’s high-purity boards (≥96% Al₂O₃) are rated for continuous use up to 1400°C, making them ideal for extreme heat environments like industrial furnaces.

Q2: What is the lead time for bulk orders?

A: Standard orders (≤10,000 sqm) ship within 25–30 days via sea freight.

Q3: Are Rosewool boards eco-friendly?

A: Absolutely. Made from natural alumina and silica, Rosewool boards contain 70–80% recycled content and are fully recyclable at end-of-life.

Q4: Can I request custom coatings for my boards?

A: Yes. Rosewool offers aluminum foil lining, low-chloride coatings, and anti-abrasion treatments to meet specific industrial needs.

Final Thoughts

Rosewool has established itself as a leader among Chinese manufacturers of ceramic fiber boards, combining technical excellence, global compliance, and customer-centric service to deliver high-performance insulation solutions. Whether you’re insulating a power plant boiler, a chemical reactor, or a renewable energy system, Rosewool’s boards offer the durability, efficiency, and reliability required for modern industrial challenges.

For global buyers seeking a trusted Chinese partner, Rosewool is more than a manufacturer—it’s a partner in innovation and success.