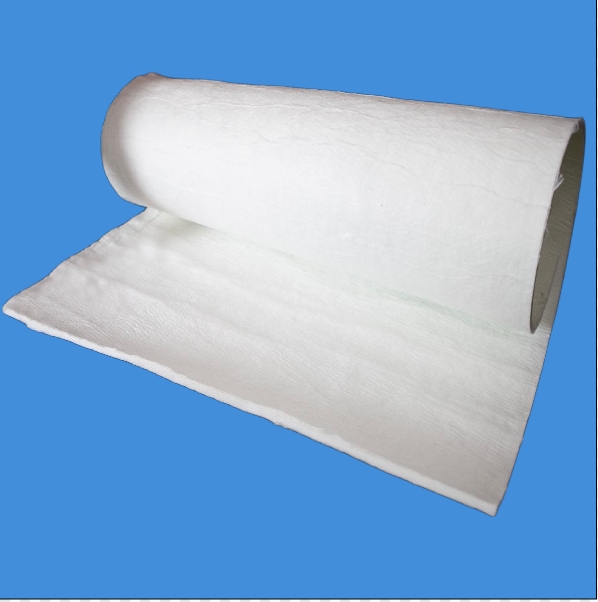

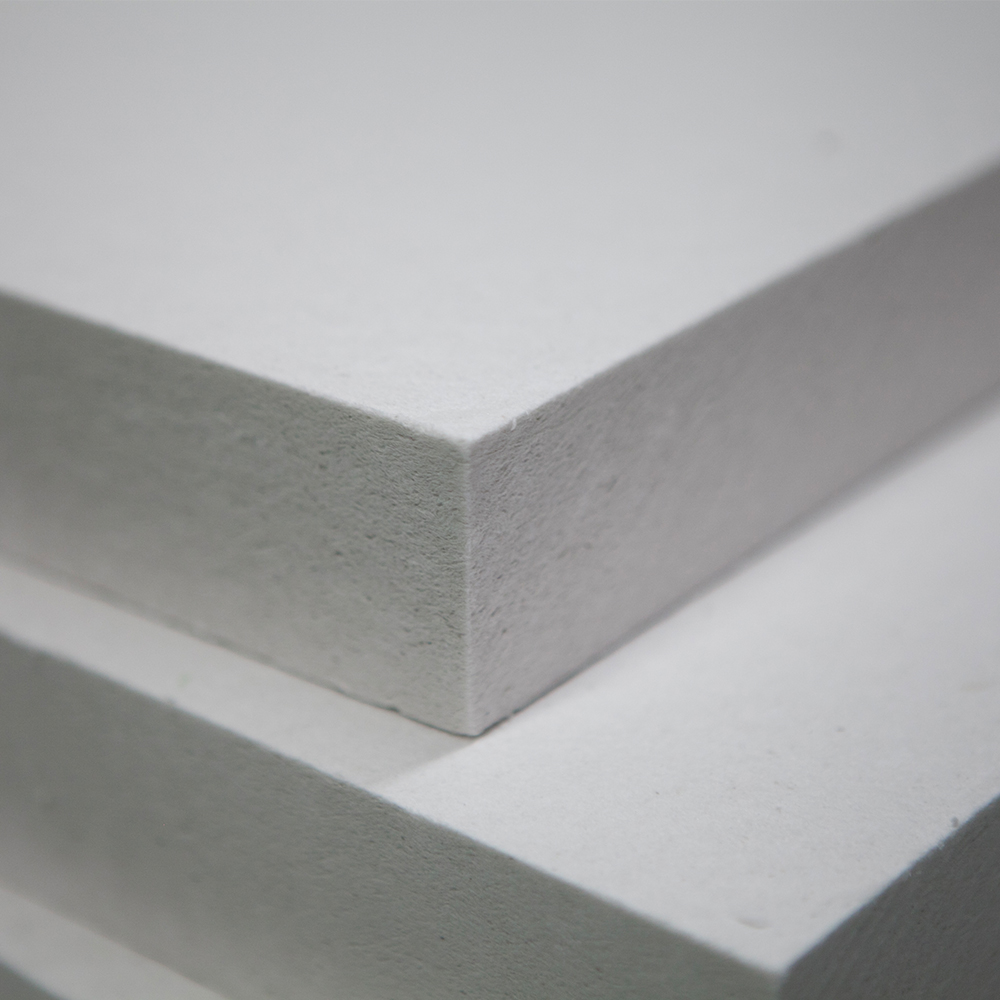

Ceramic fiber boards are indispensable in high-temperature industries like kiln construction, aerospace, and metal processing due to their exceptional thermal stability and low thermal conductivity. However, like any specialized material, they are prone to specific issues that can compromise performance if not addressed promptly. This article explores 5 critical problems with ceramic fiber boards and provides actionable solutions to maximize their lifespan and efficiency.

1. Cracking or Splitting

Problem: Hairline cracks or fractures develop during heating/cooling cycles.

Causes:

- Thermal Shock: Rapid temperature changes (>50°C/min) cause uneven expansion.

- Mechanical Stress: Improper handling or installation bending the board.

- Manufacturing Defects: Inconsistent fiber density or poor sintering.

Solutions:

- Controlled Ramping: Heat/cool at ≤30°C per minute (use programmable controllers).

- Reinforce Edges: Apply ceramic fiber tape to high-stress zones.

- Quality Check: Verify ASTM C165 (thermal shock resistance) compliance before purchase.

2. Delamination (Layer Separation)

Problem: Layers of the board peel apart, reducing insulation efficiency.

Causes:

- Moisture Ingress: Humidity weakens bond between fibers.

- Chemical Attack: Exposure to acids/alkalis degrades binders.

- Over-Firing: Temperatures exceeding 1260°C (2300°F) melt binders.

Solutions:

- Pre-Drying: Bake boards at 150°C (300°F) for 4 hours before installation.

- Seal Edges: Coat with alumina-based paint to prevent moisture absorption.

- Upgrade Grade: Use high-purity boards (e.g., 99.8% Al₂O₃) for corrosive environments.

3. Shrinkage at High Temps

Problem: Linear shrinkage >3% distorts furnace linings.

Causes:

- Low-Density Boards: Insufficient fiber compaction.

- Organic Binders: Burnout causes dimensional changes.

Solutions:

- Select High-Density Options: Choose boards with ≥280 kg/m³ density.

- Pre-Fire Testing: Confirm shrinkage rates meet ISO 12676 standards.

- Layer Compensation: Design linings with 5–10% expansion allowance.

4. Dusting or Fiber Shedding

Problem: Fiber particles detach, causing contamination risks.

Causes:

- Abrasion: Vibration or friction during transport/installation.

- Low-Grade Fibers: Short fibers (<5µm) lack cohesion.

Solutions:

- Surface Coating: Apply silica aerogel or colloidal graphite.

- Handling Protocols: Use vacuum lifters instead of clamps.

- Fiber Choice: Opt for polycrystalline wool (PCW) boards for zero-shedding needs.

5. Installation Gaps

Problem: Gaps between boards reduce thermal efficiency by up to 40%.

Causes:

- Poor Cutting Precision: Tolerances >2mm create pathways for heat.

- Warping: Uneven cooling causes boards to bow.

Solutions:

- Laser Cutting: Achieve ±0.5mm precision (vs. ±3mm with hand tools).

- Interlocking Designs: Use tongue-and-groove profiles.

- Backing Mortar: Fill gaps with refractory cement (e.g., 80% alumina).

Prevention Strategy: 3 Pillars of Longevity

- Pre-Installation Audit:

- Check boards for visual defects (cracks, delamination).

- Verify compatibility with operating temperatures (use phase diagrams).

- Operational Controls:

- Maintain <5% humidity in storage areas.

- Avoid thermal cycling >10 times/month.

- Maintenance Schedule:

- Inspect boards quarterly using infrared cameras.

- Replace boards showing >10% surface erosion.

FAQs for SEO Boost

-

Q: Can ceramic fiber boards repair themselves?

A: No. Once cracked, boards require replacement to prevent hotspots.

-

Q: What’s the maximum service life?

A: 3–5 years in continuous 1000°C use; up to 10 years with intermittent use.

-

Q: Are there eco-friendly alternatives?

A: Bio-soluble fibers (E-glass/Zirconia blends) reduce inhalation risks.

Conclusion

Proactive management of ceramic fiber board issues ensures reliable performance in critical applications. By addressing cracking, delamination, and shrinkage through controlled processes and quality materials, industries can reduce downtime by up to 35%.