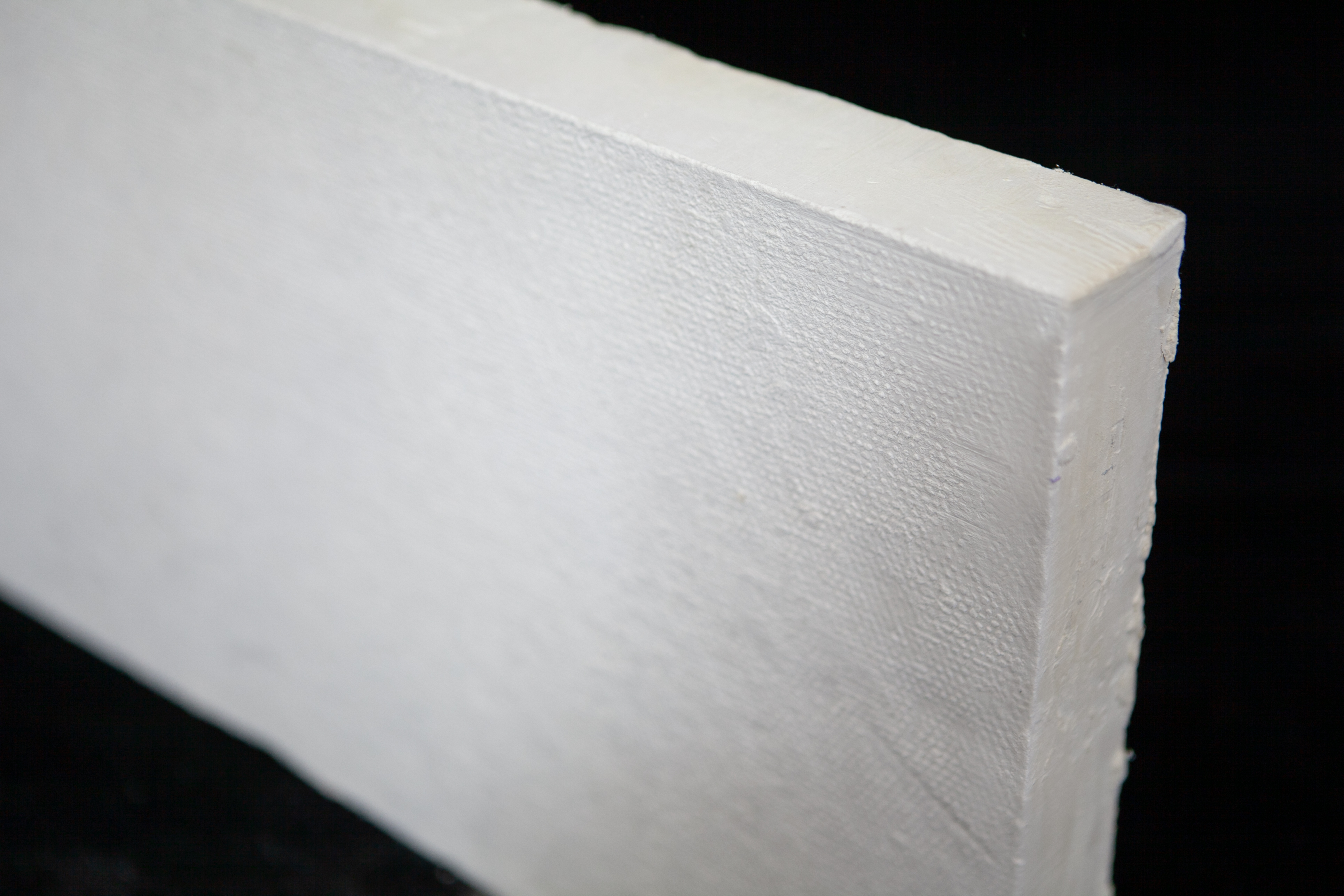

Ceramic fiber blankets are prized for their excellent heat resistance, thermal insulation, and flexibility, making them essential in various industrial and construction applications. However, improper storage can compromise their performance, durability, and lifespan. To ensure your ceramic fiber blankets maintain optimal quality, follow these comprehensive storage guidelines.

1. Choose the Right Storage Environment

The storage environment is crucial for preserving the integrity of ceramic fiber blankets. Opt for a

clean, dry, and well - ventilated area to prevent moisture absorption and contamination. Avoid storing them in basements, outdoor sheds, or areas prone to flooding, as

humidity can lead to mold growth, fiber degradation, and reduced insulation efficiency. Additionally, keep the blankets away from direct sunlight and sources of intense heat, as prolonged exposure can cause brittleness and structural weakening.

2. Protect with Proper Packaging

When not in use, ceramic fiber blankets should be stored in their

original packaging or sealed plastic containers. The packaging serves as a barrier against dust, dirt, and moisture. If the original packaging is damaged, wrap the blankets tightly with heavy - duty plastic sheeting and secure it with tape or straps. For added protection, consider using desiccant packs inside the packaging to absorb any residual moisture.

3. Stacking and Handling Techniques

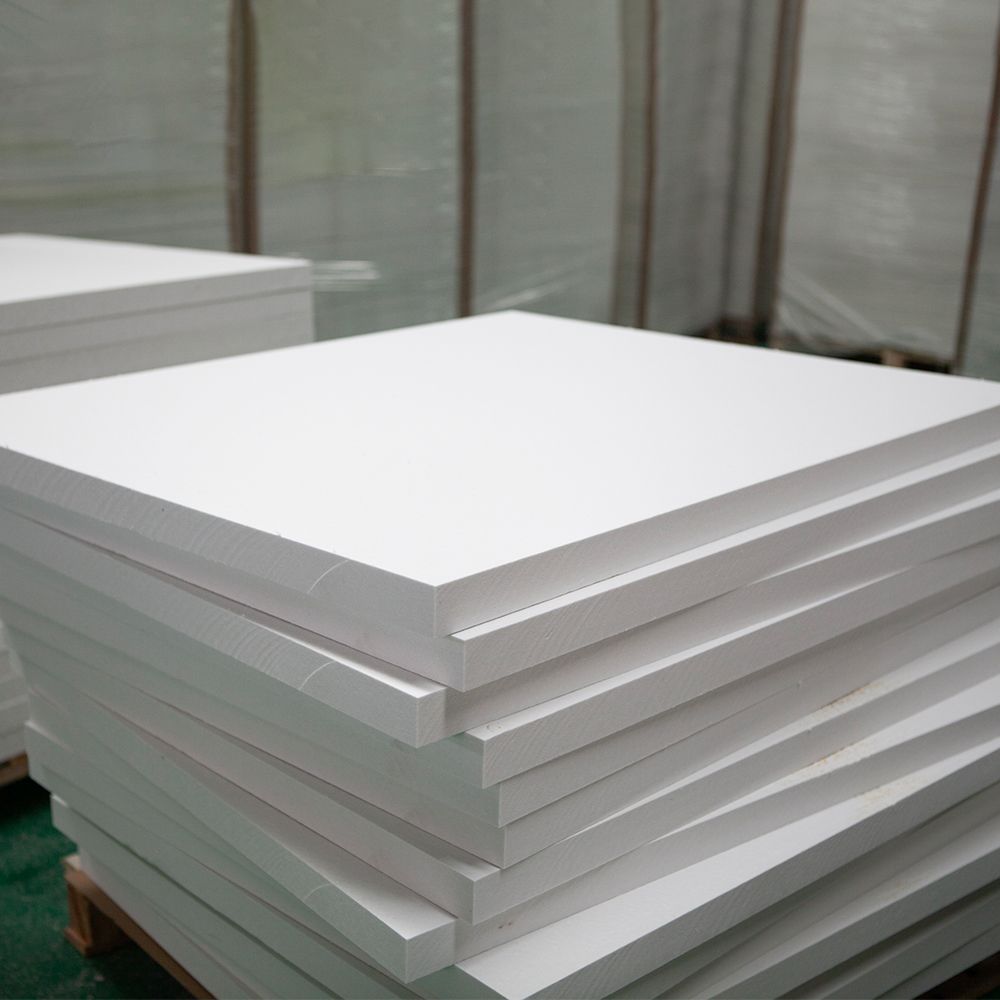

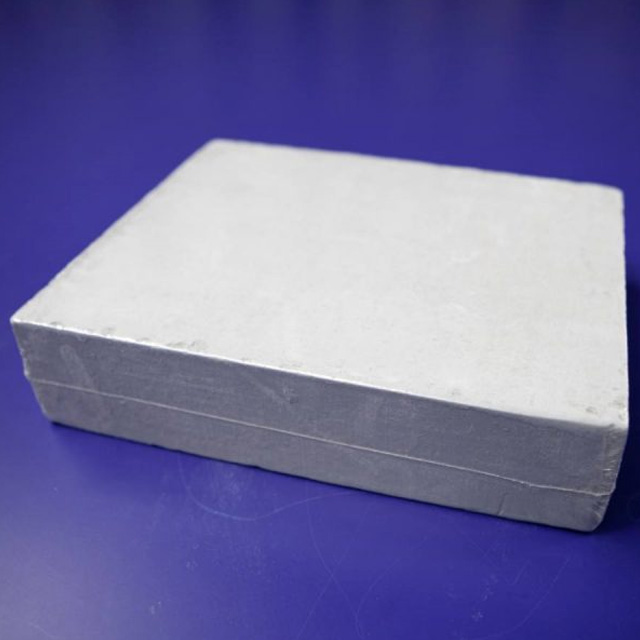

Proper stacking and handling prevent compression and damage to the fibers.

Stack the blankets flat on stable pallets or shelves, ensuring each layer is evenly distributed to avoid uneven pressure points. Limit the height of the stack to prevent excessive compression, which can reduce the blanket’s thickness and insulation performance. When moving the blankets, use

lifting equipment or handle them with clean, dry gloves to avoid tearing or snagging the fibers.

4. Organize by Type and Grade

To streamline retrieval and prevent mix - ups, organize your ceramic fiber blankets by

type, grade, and intended use. Label each stack or package clearly with details such as the material composition, temperature rating, and date of purchase. This organization not only helps in quickly identifying the right product for your project but also allows you to rotate stock efficiently, using older inventory first.

5. Regular Inspection and Maintenance

Periodically inspect stored ceramic fiber blankets for signs of damage, moisture, or pest infestation. Check for any discoloration, mold growth, or a musty odor, which may indicate moisture penetration. If any issues are detected,

remove the affected blankets immediately and assess whether they can be salvaged or need replacement. Additionally, keep the storage area clean and free of debris to maintain a hygienic environment.

6. Temperature and Chemical Considerations

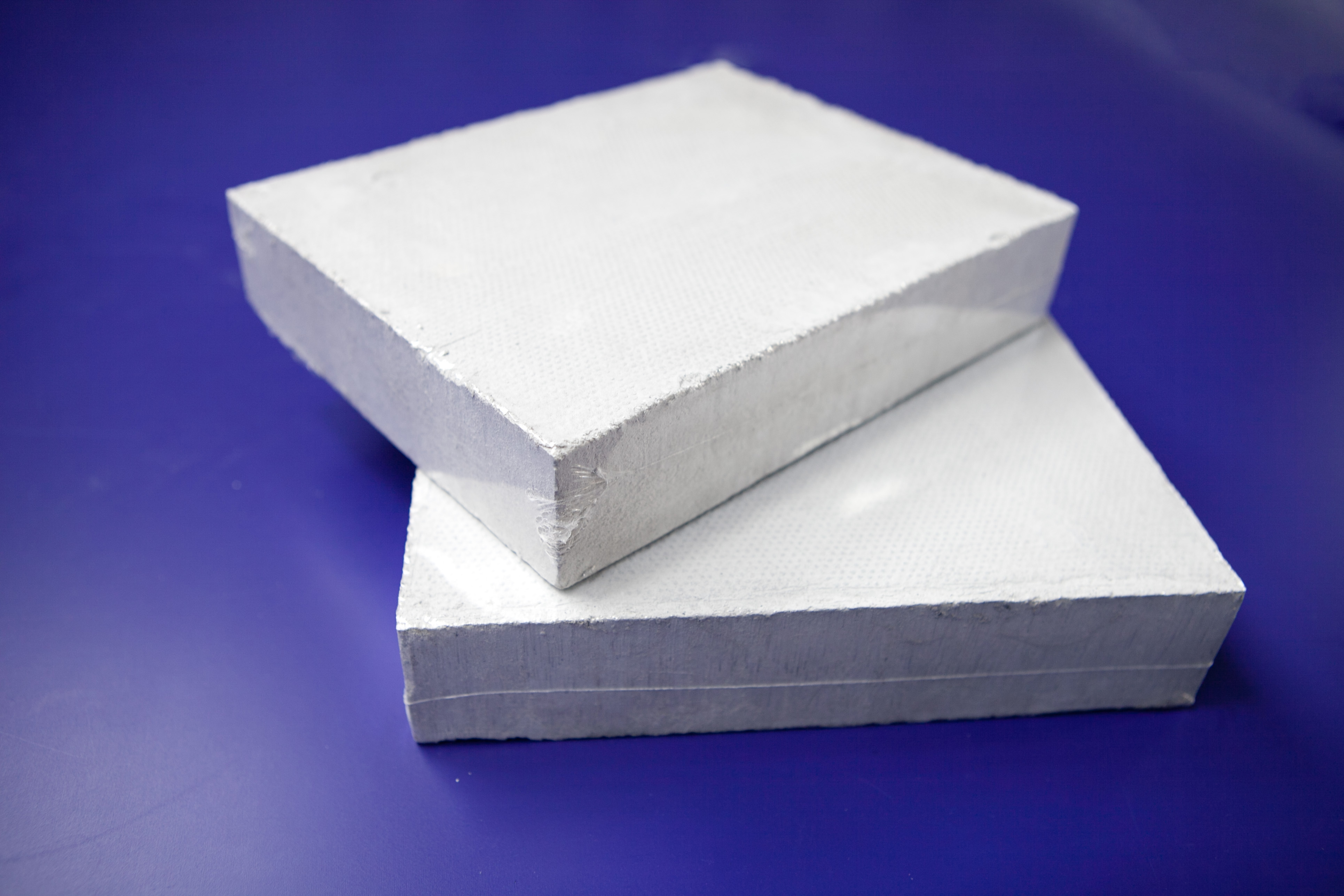

Store

ceramic fiber blankets in an environment with

stable temperature conditions. Extreme temperature fluctuations can cause the fibers to expand and contract, potentially leading to structural damage. Also, keep the blankets away from chemicals, solvents, and corrosive substances, as these can react with the fibers and degrade their performance.

7. Long - Term Storage Tips

For long - term storage, take extra precautions to ensure the blankets remain in top condition.

Vacuum - seal the blankets to reduce their volume and minimize exposure to air and moisture. Additionally, consider using a dehumidifier in the storage area to maintain a consistent low - humidity level. Before using the blankets after long - term storage, inspect them thoroughly for any signs of deterioration.