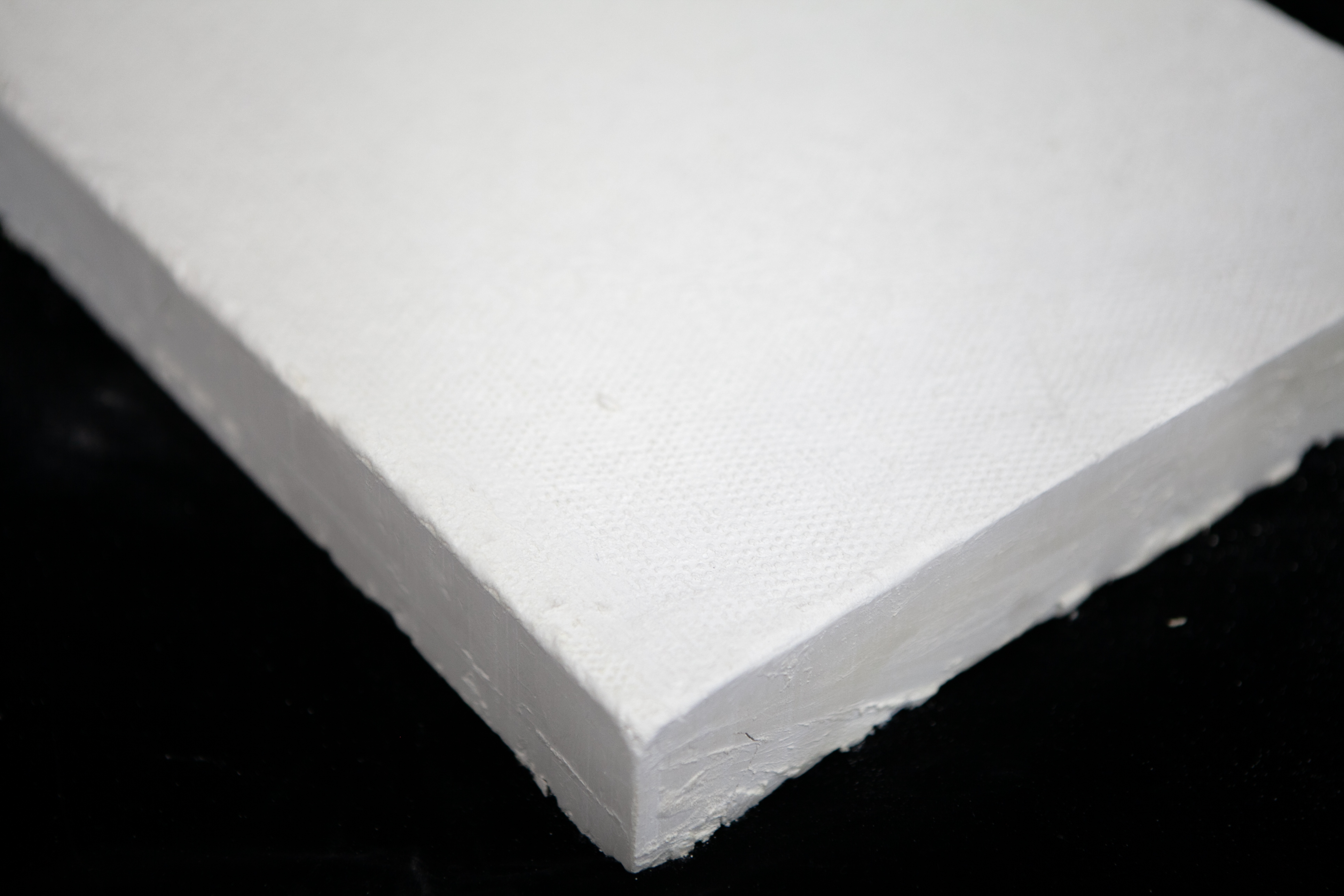

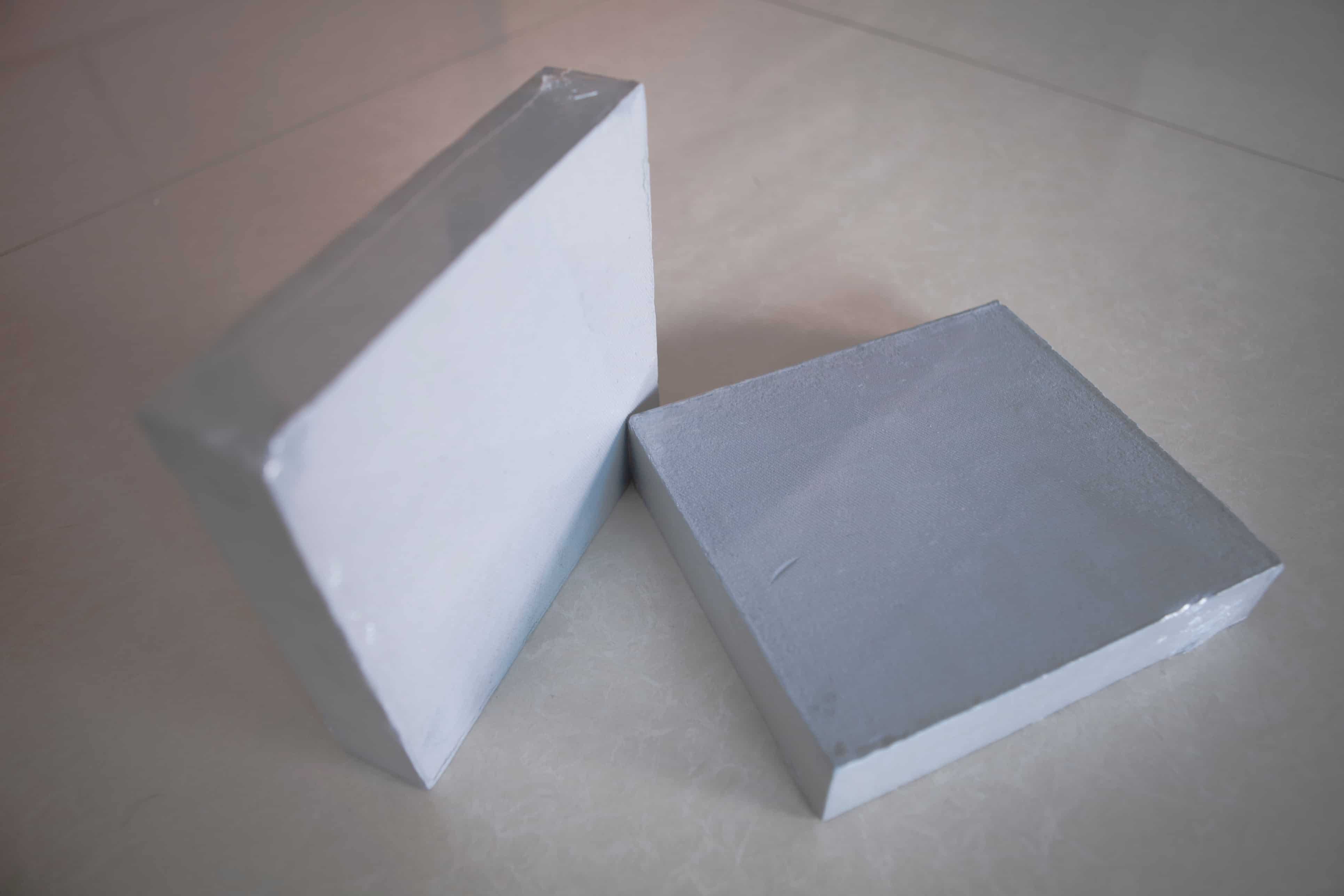

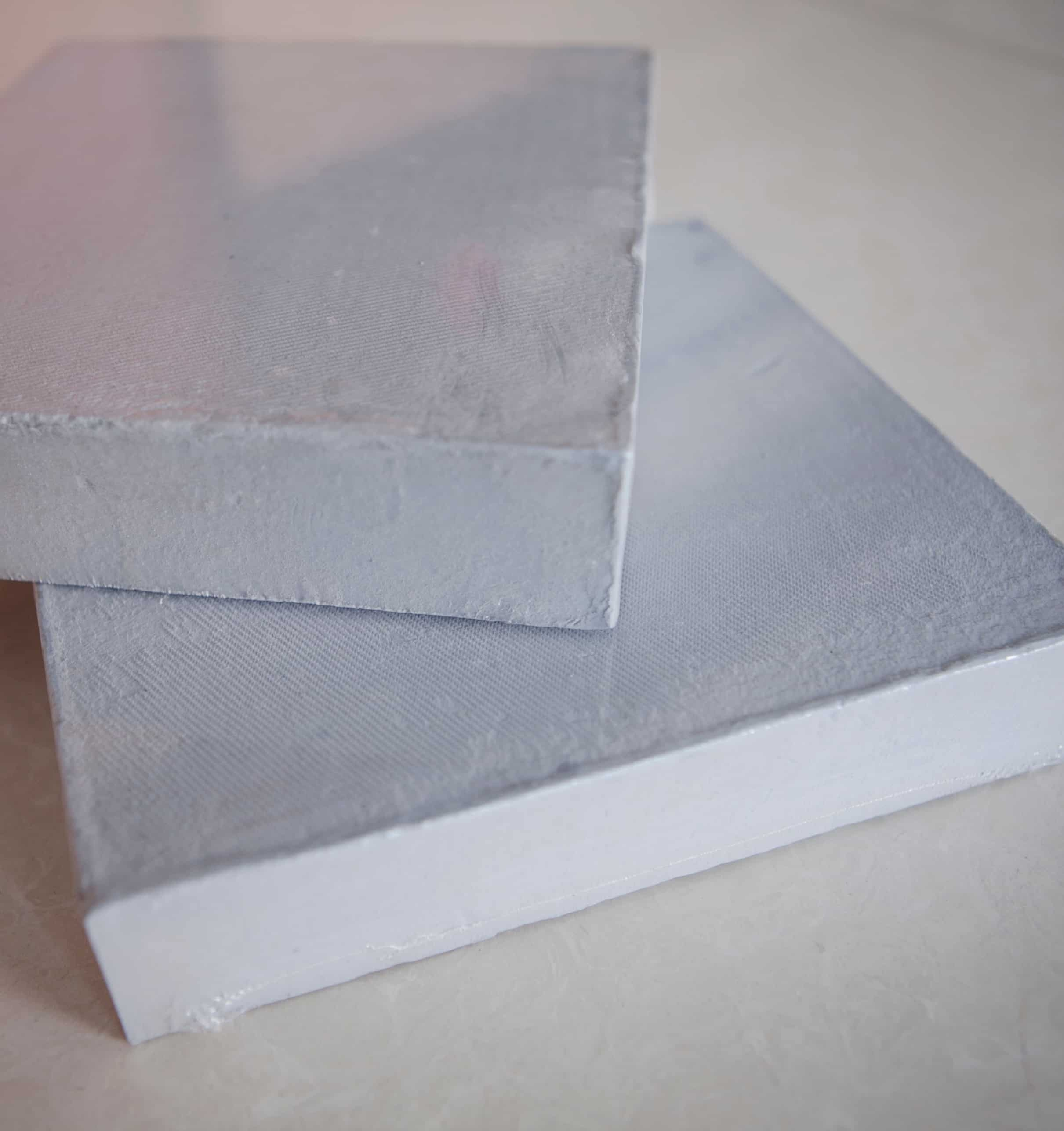

A nano insulating board, also known as a nano-insulation panel, represents a cutting-edge advancement in thermal insulation technology. Composed of nanoscale materials such as nano-silica (SiO₂), alumina fibers, or aerogel particles, this material is engineered to create a highly porous structure with exceptional thermal resistance. Its defining characteristic is ultra-low thermal conductivity, often below 0.03 W/m·K, which surpasses the insulating performance of traditional materials like ceramic fibers by up to 10 times.

Key Features and Advantages

Unmatched Thermal Efficiency: The nano-insulating board's structure inhibits all three modes of heat transfer—conduction, convection, and radiation. This results in thermal insulation performance 3-4 times superior to conventional materials, making it ideal for energy-intensive applications.

Thin Profile, Lightweight Design: Despite its high efficiency, the material is remarkably thin (as thin as 5mm) and lightweight. This reduces space requirements and structural load while maintaining optimal insulation.

Extreme Temperature Resistance: Capable of withstanding continuous operating temperatures up to 1000°C, it maintains stability in high-temperature industrial environments, aerospace applications, and fire-critical scenarios.

Fire Safety and Non-Toxicity: Classified as A-grade non-combustible, it does not emit toxic fumes when exposed to flames, enhancing safety in buildings and transportation.

Eco-Friendly Composition: Manufactured from inorganic materials, it is recyclable, non-toxic, and compliant with global environmental regulations.

Applications Across Industries

Industrial High-Temperature Equipment: Insulates furnaces, kilns, and pipelines in steel metallurgy, petrochemicals, and glass manufacturing, reducing energy consumption by up to 50%.

Aerospace and Defense: Protects spacecraft, missiles, and hypersonic vehicles from extreme thermal stress during re-entry or high-speed flight.

Construction and Architecture: Enhances building energy efficiency by serving as exterior wall, roof, and floor insulation, contributing to LEED certification and sustainable design.

Electric Vehicles (EVs): Improves battery thermal management by preventing thermal runaway and extending driving range.

Marine Engineering: Insulates ship engines, exhaust systems, and cabins, optimizing fuel efficiency and crew comfort.

Why Choose Nano Insulating Board?

In an era of rising energy costs and stricter environmental regulations, the nano insulating board offers a transformative solution. Its ability to deliver superior insulation in a thinner, lighter form factor reduces material usage, installation time, and lifecycle costs. Whether for industrial energy savings, architectural sustainability, or safety-critical applications, this material sets a new standard in thermal management.