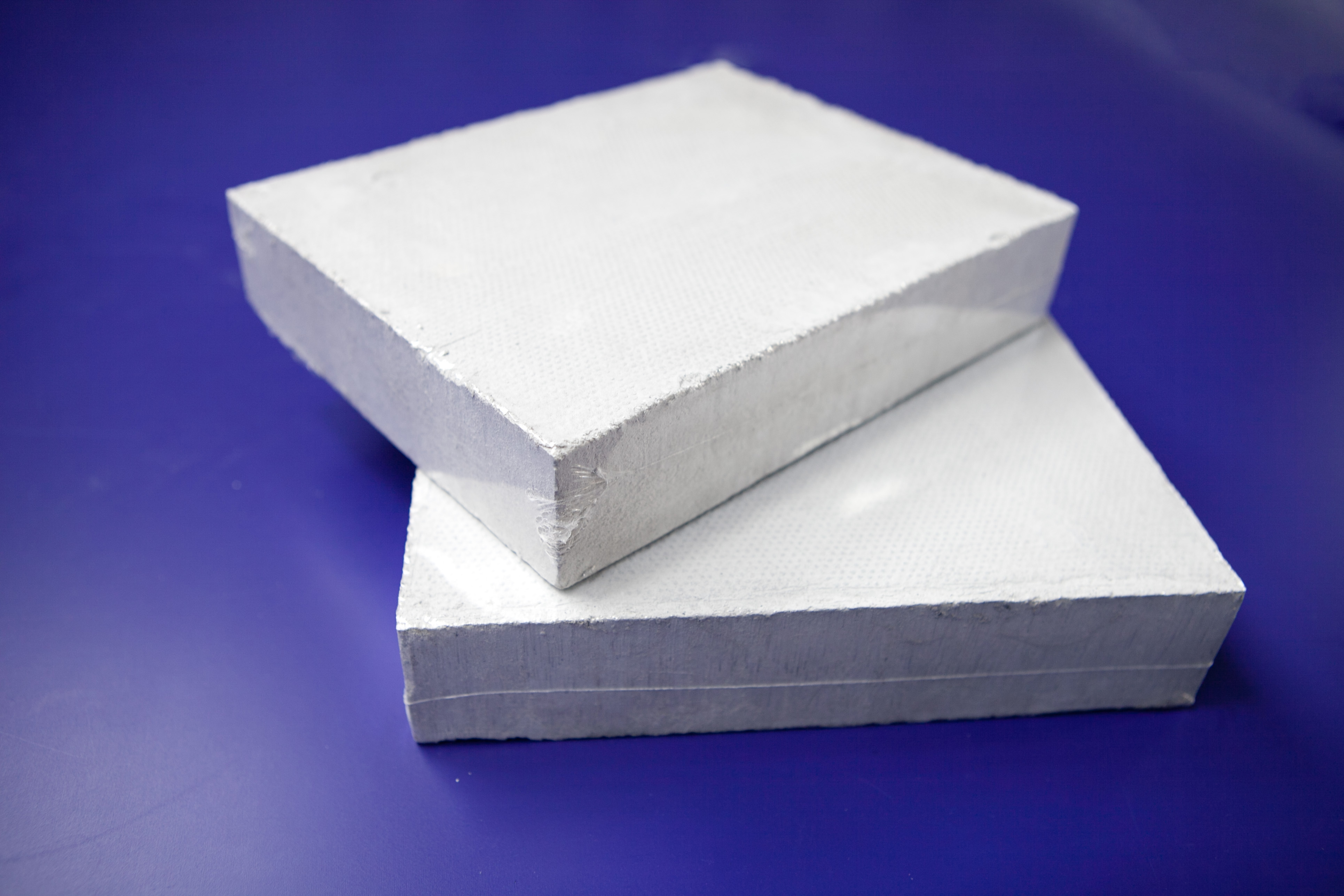

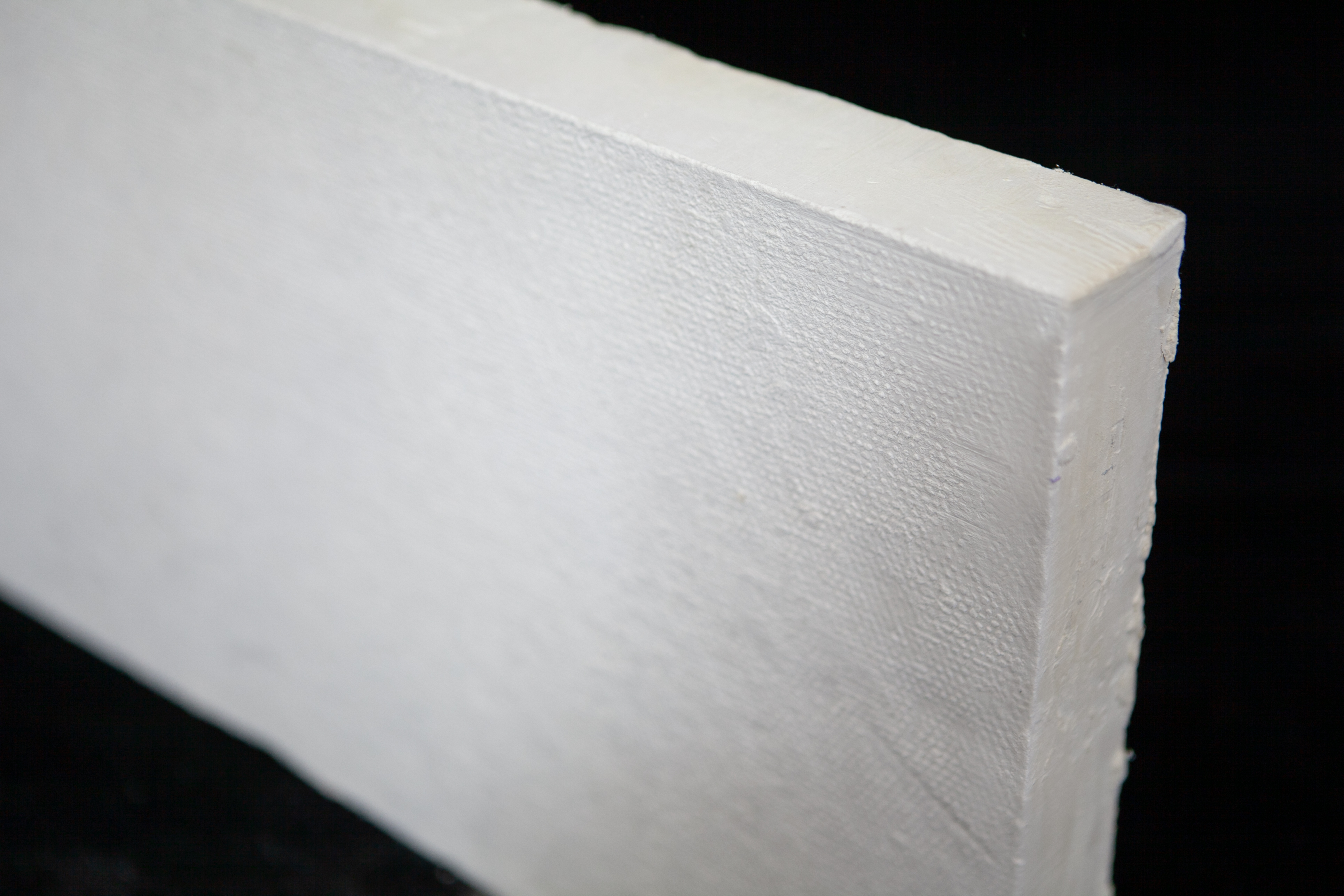

Ceramic fiber blankets are renowned for their exceptional heat resistance, lightweight design, and thermal insulation properties, making them indispensable in industries like aerospace, metallurgy, and construction. However, a common concern among users is whether these materials are prone to moisture absorption. This article explores the relationship between ceramic fiber blankets and dampness, offering insights into their durability, practical handling tips, and how to maintain their performance in varying environments.

Do Ceramic Fiber Blankets Absorb Moisture?

The short answer: No, ceramic fiber blankets are inherently resistant to moisture absorption. Unlike organic insulation materials (e.g., cotton, fiberglass), ceramic fibers are inorganic and non-porous, meaning they do not retain water. This characteristic makes them ideal for high-humidity environments, outdoor applications, or scenarios where exposure to moisture is inevitable.

Key Takeaway: The chemical structure of ceramic fibers prevents water molecules from penetrating the material, ensuring long-term stability even in damp conditions.

Factors That May Affect Moisture Resistance

While ceramic fiber blankets resist moisture, certain external factors can influence their performance:

- Prolonged Exposure to Liquid Water:

- Submerging the blanket in water for extended periods may lead to temporary weight gain due to surface saturation. However, once dried, the material typically regains its original properties.

- High Humidity + Temperature Fluctuations:

- Rapid temperature changes in humid environments can cause condensation on the blanket’s surface. Though this doesn’t damage the fibers, it may create a superficial damp appearance.

- Contaminants:

- Dust, oils, or chemicals trapped in the fibers could potentially retain moisture if not cleaned regularly.

Why Moisture Resistance Matters for Ceramic Fiber Blankets

- Thermal Stability:

- Moisture-free insulation ensures consistent heat resistance, critical for applications like furnace linings or exhaust systems.

- Longevity:

- Preventing dampness avoids issues like mold growth or corrosion, which are common in organic insulation materials.

- Safety:

- In high-temperature settings, trapped moisture could vaporize suddenly, posing a risk of steam explosions. Ceramic fibers’ non-absorbent nature mitigates this danger.

Best Practices for Handling and Storage

To maximize moisture resistance:

- Store Properly:

- Keep blankets in dry, indoor locations. Use pallets or shelves to avoid ground contact, which can trap humidity.

- Use Protective Covers:

- For outdoor storage, wrap blankets in waterproof tarps or plastic sheets.

- Avoid Mechanical Damage:

- Tears or punctures can create entry points for moisture. Handle with care during installation.

- Regular Inspections:

- Check for signs of condensation or contaminants, especially in humid climates.

What If the Blanket Gets Wet?

- Immediate Drying:

- If submerged, air-dry the blanket thoroughly before reuse. Avoid direct heat sources (e.g., heaters) to prevent uneven shrinkage.

- Inspect for Damage:

- Ensure no fibers are compromised. While rare, prolonged wetting might slightly reduce flexibility in low-quality products.

- Reapply Coatings (If Applicable):

- Some ceramic fiber blankets are treated with reflective or adhesive coatings. Reapply these if moisture causes peeling.

Industries That Benefit From Ceramic Fibers’ Moisture Resistance

- Marine & Offshore: Insulation for ship engines and pipelines exposed to saltwater spray.

- Food Processing: Oven linings and ductwork in humid production environments.

- Chemical Plants: Resistance to both heat and accidental spills.

Conclusion: A Reliable Choice for Damp Environments

Ceramic fiber blankets are engineered to withstand moisture without compromising performance. Their inorganic composition and low thermal conductivity make them a top choice for applications where humidity is a concern. By following proper storage and maintenance practices, users can ensure these materials deliver decades of reliable service.

Final Tip: Always consult your supplier for product-specific guidelines, as formulations may vary. For projects in extremely wet or corrosive settings, consider reinforced options like ceramic fiber composites with added moisture barriers.