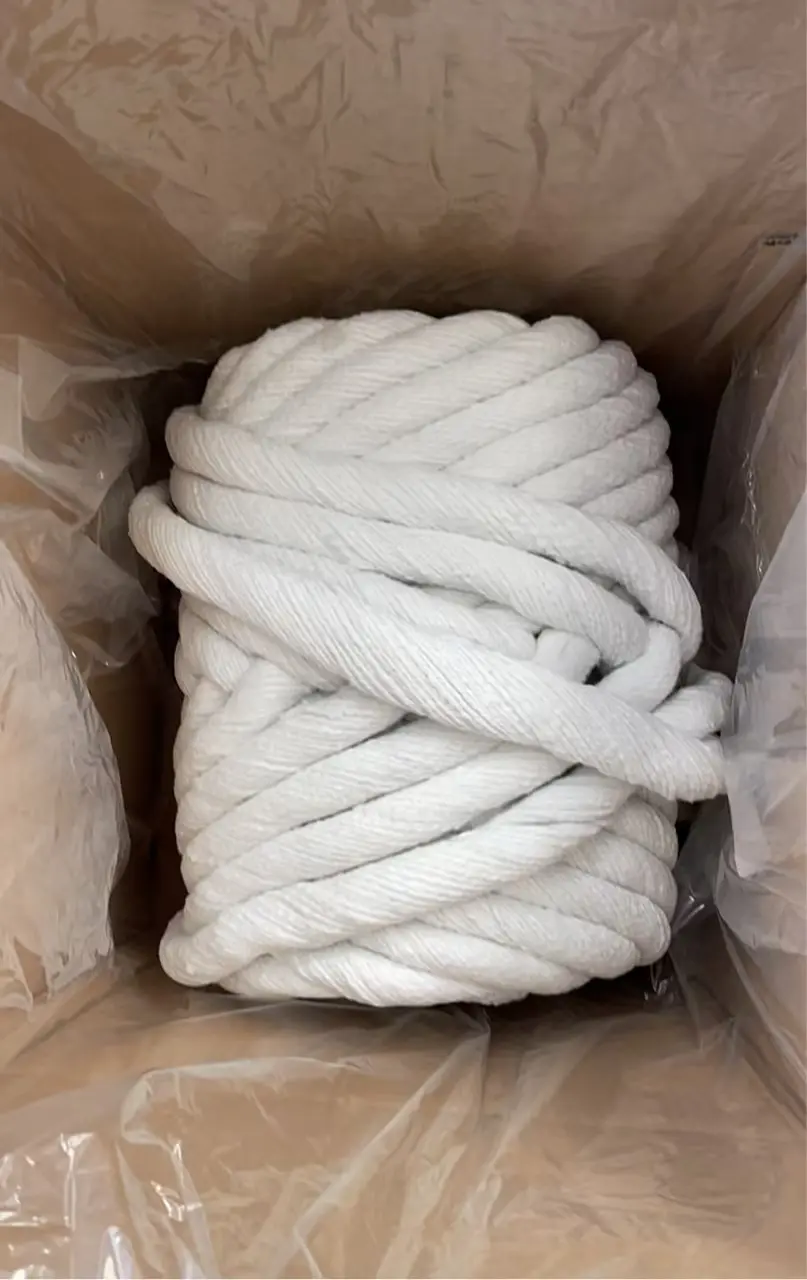

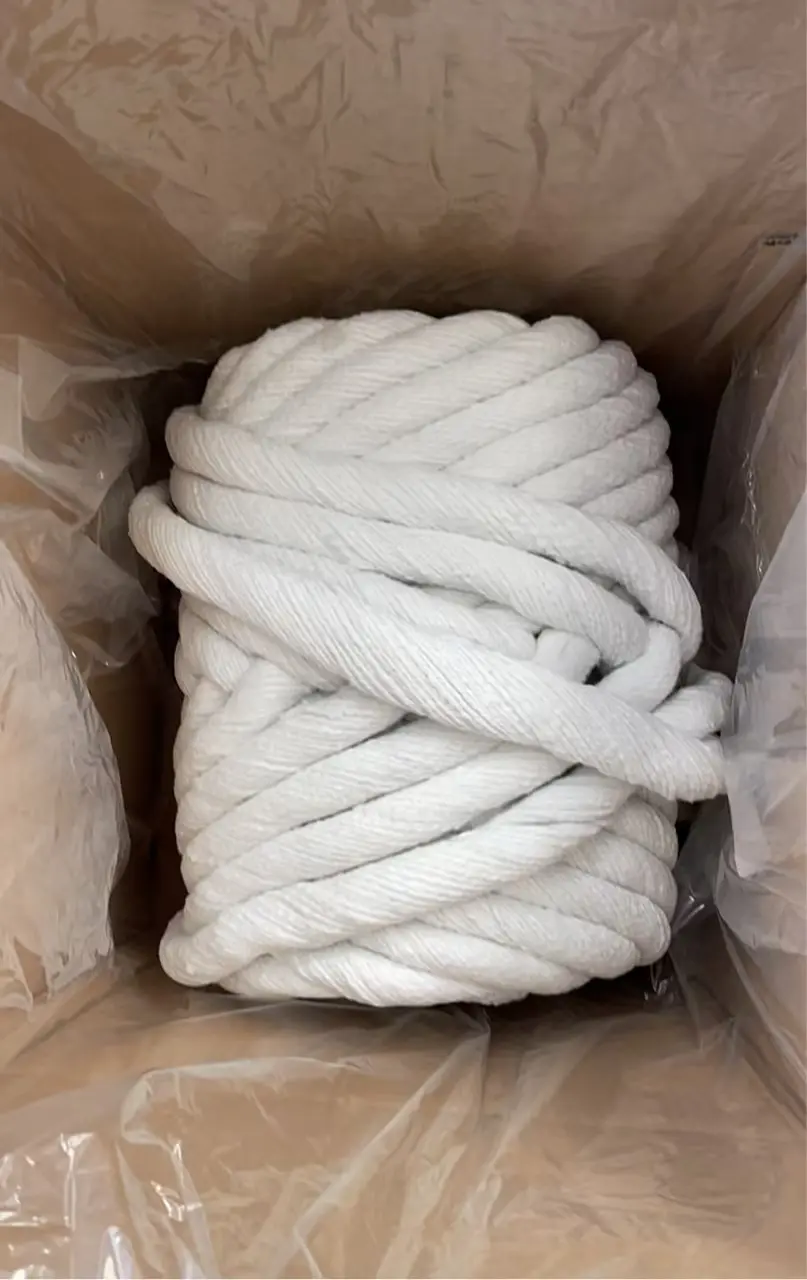

Ceramic fiber ropes, engineered from high-purity alumina-silicate fibers, are indispensable in extreme-temperature industrial environments for their flexibility, durability, and unmatched thermal resistance. Whether sealing furnace joints, isolating molten metal, or protecting critical valves, these ropes prevent energy loss, ensure safety, and extend equipment life. Here’s a comprehensive breakdown of their core industrial applications:

Top 5 Industrial Uses of Ceramic Fiber Ropes

1. High-Temperature Sealing & Insulation

Applications:

- Kiln/Furnace Doors: Seals gaps in steel, glass, and ceramic kilns (up to 1260°C/2300°F), preventing 95% of heat leakage.

- Boiler Expansion Joints: Absorbs thermal movement in power plant boilers, reducing stress cracks.

- Valve & Flange Gaskets: Creates leak-proof seals for high-pressure steam valves (DN50–DN500 pipes).

Key Benefits:

- Heat Retention: Cuts energy loss by up to 40% in furnaces.

- Zero Maintenance: Withstands 5–8 years of thermal cycling without brittleness.

2. Fireproofing & Fire Barriers

Applications:

- Fire-Rated Doors/Windows: Braided ceramic ropes line perimeters, blocking smoke/flames for 2+ hours (certified to EN 1366-3).

- HVAC Fire Dampers: Seals duct joints during fires to prevent toxic fume spread.

- Electrical Conduit Seals: Contains fires in cable penetrations (ASTM E814 compliant).

Key Benefits:

- Non-Combustible: Class A1 rating (EN 13501) – melts only above 1760°C.

- Toxic Fume Prevention: Zero halogen/volatile organic compound (VOC) emissions.

3. Molten Metal & Foundry Protection

Applications:

- Ladle/Furnace Spout Seals: Wrapped around molten metal transfer points (iron, aluminum, copper).

- Casting Mold Seals: Lines mold joints to prevent metal leakage.

- Welding Curtains: Heat-resistant barriers for foundry workstations.

Key Benefits:

- Resists Molten Metal Splash: High-purity fibers remain inert at 1450°C.

- Thermal Shock Resistance: Handles rapid temperature swings (e.g., 25°C → 1200°C in seconds).

4. Petrochemical & Chemical Processing

Applications:

- Reactor Vessel Seals: Seals flanges in sulfuric acid/nitric acid reactors (pH 1–14 resistance).

- Pipeline Insulation: Wraps high-temp pipes carrying crude oil (~300°C).

- Burner Ignition Port Seals: Withstands gas flare cycling in refineries.

Key Benefits:

- Corrosion Immunity: Resists chlorides, sulfides, and alkalis.

- Explosion Safety: Prevents gas leaks in API 607-certified valves.

5. Aerospace & Automotive Thermal Management

Applications:

- Rocket Engine Seals: Insulates liquid fuel combustion chambers.

- Exhaust Manifold Wrapping: Reduces under-hood temperatures in race cars (peak 1100°C).

- Battery Fire Barriers: Segregates EV battery modules to contain thermal runaway.

Key Benefits:

- Weight Savings: 60% lighter than metal seals (density: 180–220 kg/m³).

- Vibration Tolerance: Reinforced with Inconel wire for aerospace-grade stability.

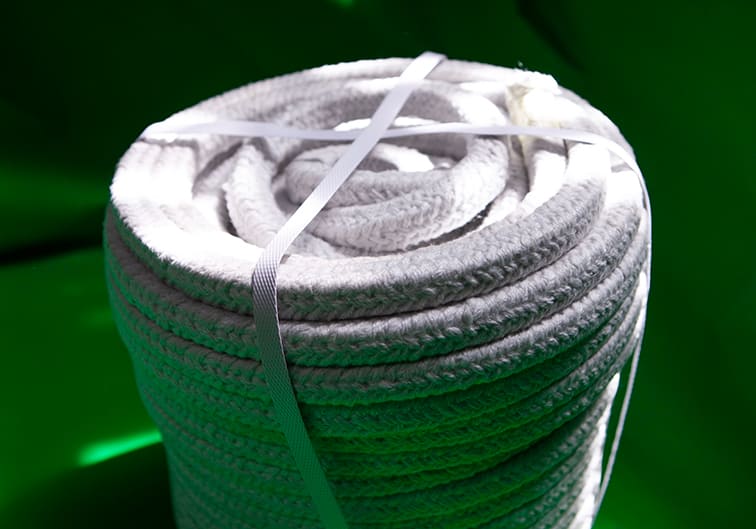

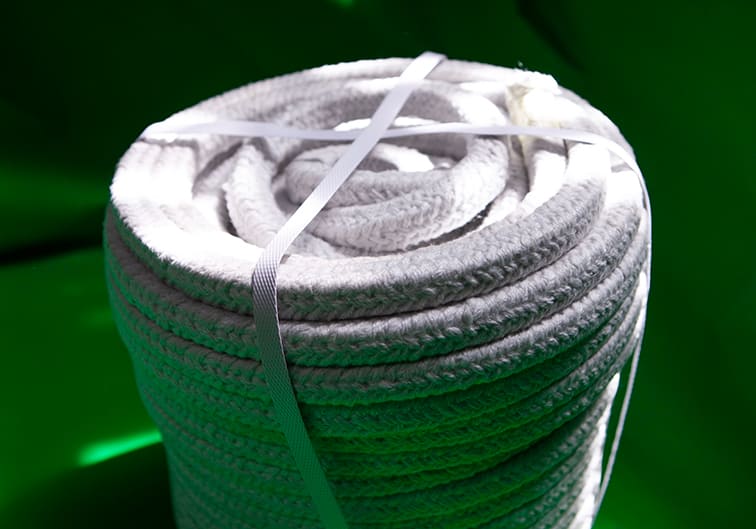

Ceramic Fiber Rope Types & Selection Guide

| Type |

Max Temp |

Reinforcement |

Best For |

| Standard Braided |

1100°C |

– |

Boiler doors, HVAC seals |

| Glass Fiber Reinforced |

650°C |

E-Glass strands |

Low-temp valves, ovens |

| SS Wire Reinforced |

1260°C |

304/316 stainless wire |

Foundries, pipelines |

| High-Purity |

1430°C |

Inconel wire |

Aerospace, chemical reactors |

Tip: Use 6–25mm ropes for gaps ≤10mm; 25–90mm for large joints/curtains.

Case Study: Solving Heat Leakage in a Steel Plant

Problem: A European steel mill lost 22% heat through gaps in its billet furnace doors (operating at 1150°C). Traditional ceramic blankets failed within months.

Solution:

- Installed 15mm SS wire-reinforced ropes (density: 210 kg/m³) around door edges.

- Sealed joints with high-temp silicate adhesive.

Results:

- Heat retention: Energy consumption dropped 15%.

- Lifespan: Ropes lasted 4 years (vs. 8 months for blankets).

Q1: Can ceramic ropes handle direct flame contact?

A: Yes – non-combustible fibers resist direct flames up to 1430°C (high-purity grade).

Q2: How are they installed?

A: Pressed into joints with sealant or mechanically clamped (e.g., furnace doors).

Q3: Are they safer than asbestos?

A: Absolutely – ceramic fibers are non-carcinogenic (REACH/OSHA compliant).

Q4: Do they absorb moisture?

A: Hydrophobic – repels water while retaining flexibility.

Q5: Can they be reused?

A: No – high-temperature exposure alters fiber structure permanently.