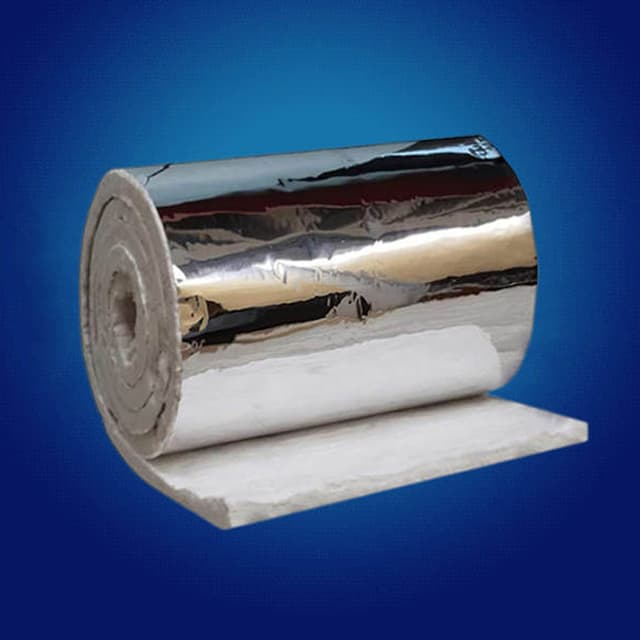

Ceramic fiber blankets have become the go-to insulation solution for industries battling extreme heat, energy inefficiency, and safety challenges. this lightweight, high-performance material is replacing traditional refractories like mineral wool and firebrick. Here’s a deep dive into the 7 key benefits driving this shift, supported by technical data, real-world applications, and cost analysis.

1. Unmatched Temperature Resistance (Up to 1430°C)

Ceramic fiber blankets excel in extreme heat environments, outperforming most alternatives:

| Material |

Max Operating Temp |

Thermal Conductivity (600°C) |

| Ceramic Fiber Blanket |

1430°C |

0.12 W/m·K |

| Mineral Wool |

800°C |

0.25 W/m·K |

| Firebrick |

1200°C |

1.0 W/m·K |

Applications:

- Steelmaking: Ladle covers, tundish linings.

- Petrochemical: Cracking furnace insulation.

- Aerospace: Rocket engine test stand protection.

2. Energy Savings of 20-40%

By drastically reducing heat loss, ceramic fiber blankets lower fuel consumption and carbon emissions:

- Case Study: A glass factory reduced natural gas usage by 28% after lining its 1350°C melter with 50mm zirconia-enhanced blankets.

- Thermal Efficiency: Low thermal conductivity (0.12 W/m·K at 600°C) traps heat 8x better than firebrick.

Cost Savings:

- ROI Calculation: A 10,000blanketinstallationcansave50,000/year in energy costs for a mid-sized furnace.

3. Lightweight & Easy to Install

Weighing 90% less than traditional firebrick, ceramic fiber blankets simplify logistics and labor:

- Weight Comparison:

- Ceramic fiber blanket (128 kg/m³): 1.3 kg/m² (25mm thickness).

- Firebrick (2300 kg/m³): 57.5 kg/m² (114mm thickness).

- Installation Speed: A furnace reline takes 3 days vs. 2 weeks for brickwork.

Installation Tips:

- Use 304 stainless steel anchors spaced ≤300mm apart.

- Layer blankets with 15% compression to eliminate gaps.

4. Superior Safety: Fireproof & Non-Toxic

Ceramic fiber blankets meet stringent safety standards:

- Fire Rating: Class A/1 (non-combustible per ASTM E136).

- Toxicity: Complies with NEC Directive 97/69/EC (low biopersistence fibers).

- Chemical Resistance: Unaffected by oil, steam, or acidic flue gases.

Safety Certifications:

- ISO 22459: Safe handling guidelines.

- REACH & RoHS: Free of asbestos, silica, and heavy metals.

5. Longevity & Low Maintenance

Properly installed blankets last 5-10 years, even in harsh conditions:

- Thermal Stability: ≤2% linear shrinkage at 1260°C (ASTM C892).

- Erosion Resistance: Needle-punched blankets withstand gas velocities up to 30 m/s.

Maintenance Best Practices:

- Inspect annually for surface cracks.

- Apply alumina-silicate coating to high-erosion zones.

6. Versatility Across Industries

From heavy industry to high-tech sectors, ceramic fiber blankets adapt to diverse needs:

| Industry |

Use Case |

Key Benefit |

| Power Generation |

Gas turbine insulation |

Reduces casing heat to 65°C |

| Automotive |

Exhaust system heat shields |

Cuts under-hood temps by 40% |

| Foundries |

Molten metal ladle liners |

Prevents skull formation |

| Semiconductor |

CVD reactor insulation |

Ensures process temperature stability |

7. Environmental Sustainability

Ceramic fiber supports green manufacturing goals:

- Recyclability: Crushed blankets can be reused as loose insulation fill.

- Carbon Footprint: Production emits 60% less CO₂ vs. firebrick (per kg).

- Waste Reduction: Modular installation minimizes cutting scraps.