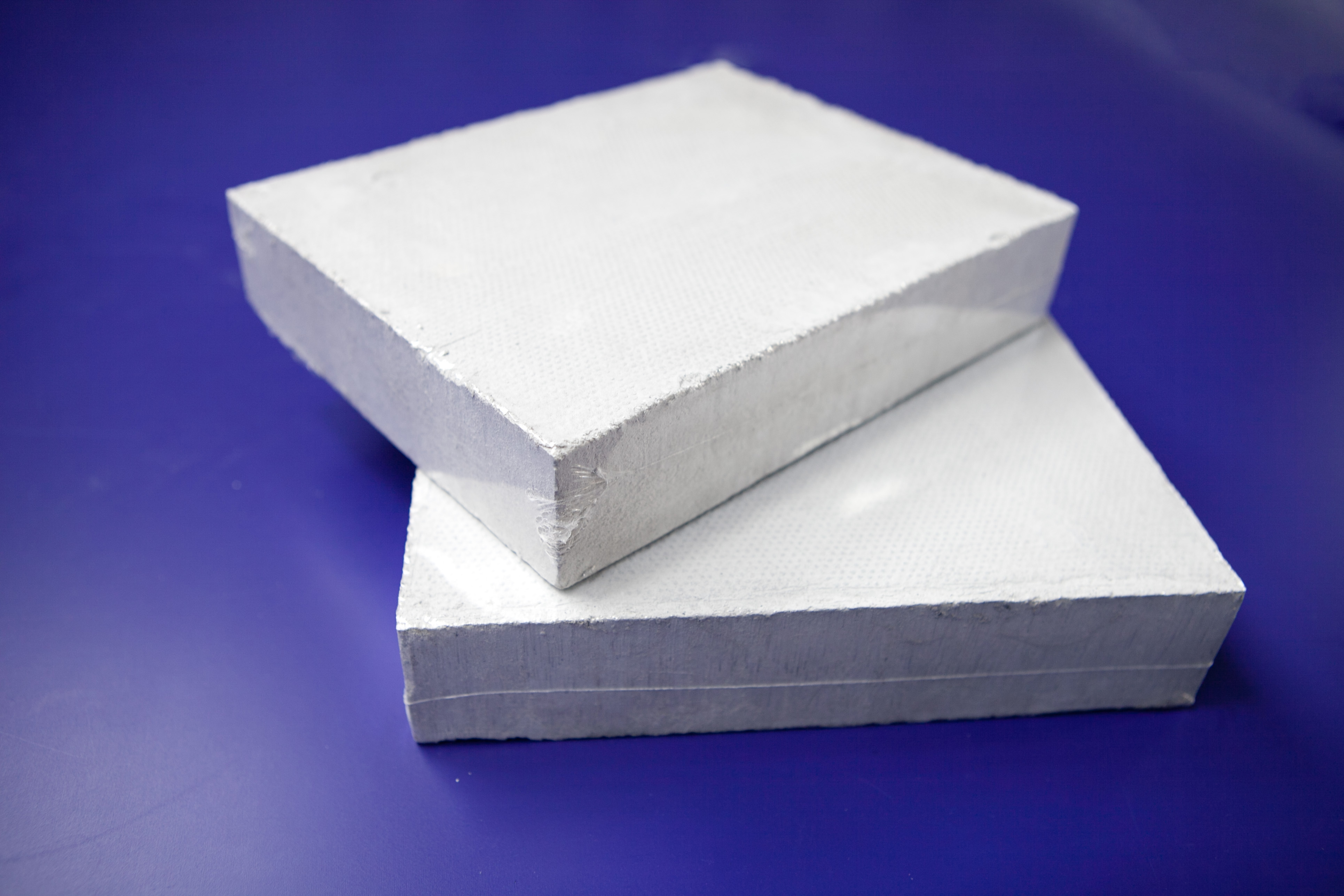

Ceramic fiber boards are highly valued for their exceptional heat resistance, thermal insulation, and fireproof properties, making them indispensable in industrial furnaces, kilns, power plants, and various high - temperature applications. However, cracking can occur due to improper handling, harsh operating conditions, or inadequate installation, which not only reduces their performance but also shortens their lifespan. Understanding effective prevention methods is crucial for maximizing the durability and functionality of ceramic fiber boards.

Proper Installation Techniques

1. Surface Preparation

Before installing ceramic fiber boards, ensure that the substrate surface is clean, flat, and dry. Any dust, debris, or moisture can create an uneven base, leading to stress points that may cause cracking. Use a vacuum cleaner or compressed air to remove dust, and if necessary, sand down rough areas to achieve a smooth surface. For metal substrates, apply an anti - corrosion coating to prevent rust from expanding and damaging the boards over time.

2. Correct Fixing Methods

Select the appropriate fixing materials and techniques based on the application. Mechanical fasteners like stainless - steel screws or anchors are commonly used. When inserting fasteners, avoid over - tightening, as excessive pressure can crack the boards. Instead, apply a consistent and moderate force to secure the boards firmly without causing damage. In some cases, adhesive bonding can be an alternative, but ensure that the adhesive is compatible with ceramic fiber materials and suitable for high - temperature environments.

3. Expansion Joints

Ceramic fiber boards expand and contract with temperature changes. Incorporating expansion joints during installation allows the material to move freely, reducing internal stress. Calculate the size and spacing of expansion joints according to the expected temperature range and the dimensions of the installation area. A general rule is to leave a gap of 1 - 2 mm per meter of board length, which can be filled with a flexible ceramic fiber rope or blanket to maintain insulation integrity.

Optimizing Operating Conditions

1. Gradual Temperature Changes

Avoid subjecting ceramic fiber boards to sudden and extreme temperature fluctuations. Rapid heating or cooling can generate thermal shock, causing the material to crack. When starting up or shutting down equipment, increase or decrease the temperature gradually. For example, in a furnace, raise the temperature at a rate of no more than 50 - 100°C per hour, depending on the size and design of the equipment. This allows the ceramic fiber boards to adjust slowly and evenly to the temperature changes.

2. Control of Mechanical Stress

Minimize mechanical stress on the ceramic fiber boards. In industrial settings, vibrations from machinery or impacts from tools can weaken the boards and lead to cracking. Install vibration - damping pads or isolators to reduce the transfer of vibrations to the boards. When handling or moving equipment that contains ceramic fiber boards, use proper lifting and support techniques to prevent accidental impacts or bending of the boards.

3. Protection from Chemical Corrosion

Some chemical substances can react with ceramic fiber materials and cause degradation, making them more prone to cracking. In environments where chemicals are present, such as chemical plants or areas with corrosive gases, choose ceramic fiber boards with enhanced chemical resistance. Additionally, consider applying a protective coating to the boards to shield them from chemical exposure. Regularly monitor the operating environment for any signs of chemical leakage or contamination and take prompt corrective actions.

Regular Maintenance and Inspection

1. Visual Inspections

Conduct routine visual inspections of ceramic fiber boards. Look for any signs of cracks, surface damage, or displacement. Check for areas where the boards may be in contact with sharp edges or other abrasive materials, as these can initiate cracking. Early detection of minor cracks allows for timely repairs, preventing them from spreading and causing more extensive damage.

2. Cleaning and Dust Removal

Keep the

ceramic fiber boards clean by regularly removing dust and debris. Accumulated dust can act as an abrasive, scratching the surface of the boards and weakening their structure. Use a soft - bristle brush or a low - pressure vacuum cleaner to gently clean the boards. Avoid using harsh cleaning agents that may damage the material.

3. Repair and Replacement

If cracks are detected, repair them immediately using appropriate ceramic fiber repair materials. For small cracks, a ceramic fiber - based adhesive or patch can be applied. However, if the cracks are extensive or the board's structural integrity is severely compromised, replace the damaged board promptly to maintain the overall performance and safety of the system.

In conclusion, preventing the cracking of ceramic fiber boards requires a combination of proper installation, optimized operating conditions, and regular maintenance. By following these strategies, users can extend the lifespan of ceramic fiber boards, ensure their reliable performance in high - temperature applications, and avoid costly repairs and replacements.