Calcium silicate board, celebrated for its fire resistance, thermal insulation, and durability, has firmly established itself as a staple in construction and industrial applications. However, like any material, it comes with its own set of drawbacks. Understanding these limitations is crucial for architects, contractors, and DIY enthusiasts aiming to make informed decisions for their projects. Here, we delve into the key disadvantages of calcium silicate board.

Higher Initial Cost

One of the most significant drawbacks of

calcium silicate board is its relatively high price tag. The manufacturing process involves a complex combination of high - temperature autoclaving and precise material mixing, including calcium oxide, silicon dioxide, and reinforcing fibers. These intricate production methods drive up costs, making calcium silicate board approximately 20 - 30% more expensive than common alternatives like gypsum board. For large - scale construction projects with tight budgets, this price differential can have a substantial impact on the overall expenditure, potentially forcing project managers to seek more affordable materials.

Difficult Machining and Installation

Calcium silicate board's dense and rigid structure makes it a challenging material to work with. Unlike softer building materials, it requires specialized tools such as diamond - tipped saws and carbide - tipped drills for cutting and shaping. The hardness of the board often leads to increased wear and tear on tools, further adding to the project cost. Additionally, the installation process demands skilled labor. Inexperienced installers may struggle to achieve precise cuts and secure proper fittings, which can result in gaps and reduced performance. In a recent renovation project, the installation team reported spending almost 40% more time installing calcium silicate board partitions compared to standard drywall, highlighting the time - consuming nature of the process.

Heavier Weight

Compared to many other insulation and building materials, calcium silicate board is notably heavier. This increased weight presents several challenges. During transportation, it requires more robust handling equipment and can contribute to higher shipping costs. In construction, the added load on building structures must be carefully considered. For example, when using calcium silicate board for ceiling installations, additional structural support may be necessary to ensure the integrity of the building, which can drive up construction costs and complexity. The weight also makes on - site handling more difficult, potentially increasing the risk of workplace injuries.

Limited Aesthetic Appeal

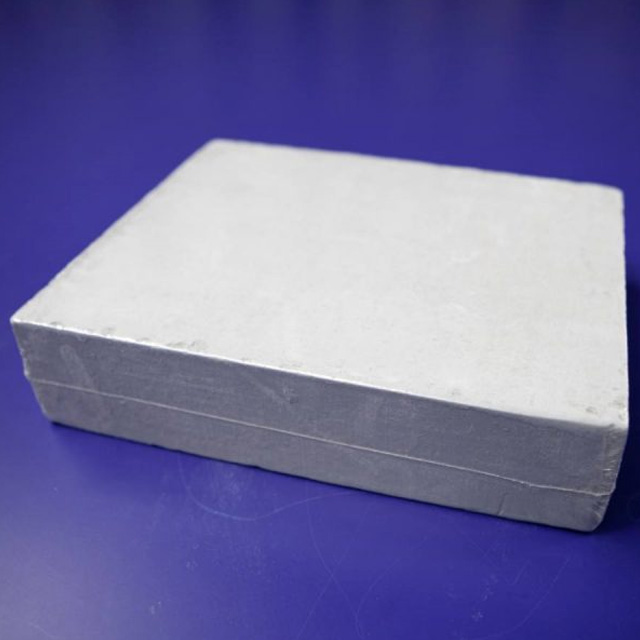

In its natural state,

calcium silicate board has a rather plain and industrial appearance. Its neutral, matte finish lacks the visual appeal desired for many interior applications. While it can be painted, tiled, or veneered to enhance its look, these additional finishing steps add both time and cost to the project. In contrast, materials like decorative plywood or certain types of gypsum board offer more aesthetically pleasing options right out of the box, eliminating the need for extensive finishing work.

Health and Safety Concerns

When calcium silicate board is cut or machined, it generates fine dust particles. These particles may contain silica, which, if inhaled, can pose significant health risks, including respiratory issues and long - term lung damage. To mitigate these risks, workers must use proper personal protective equipment (PPE), such as dust masks and goggles, and ensure adequate ventilation during the cutting process. However, in some construction sites, especially those with less stringent safety protocols, these precautions may not always be strictly followed, putting workers' health at risk.

Susceptibility to Cracking Under Impact

Despite its overall strength, calcium silicate board can be prone to cracking when subjected to sudden, high - impact forces. In areas where the board may be exposed to physical impacts, such as in commercial kitchens or high - traffic corridors, this vulnerability can lead to premature damage and the need for repairs or replacements. Compared to more flexible materials, calcium silicate board offers less resilience in the face of impacts, which can be a significant drawback in certain applications.

In conclusion, while calcium silicate board offers a range of valuable properties, it's essential to consider its disadvantages carefully. From higher costs and difficult installation to aesthetic limitations and health concerns, these drawbacks can influence the suitability of the material for different projects. By being aware of these limitations, construction professionals and homeowners can make more informed decisions, ensuring that the chosen materials align perfectly with their project requirements and expectations.