In the dynamic landscape of modern construction and industrial materials, calcium silicate board has emerged as a versatile and high - performance solution, gaining widespread recognition for its exceptional properties and diverse applications. But what exactly is

calcium silicate board, and why has it become a preferred choice for architects, builders, and industrial professionals?

Definition and Composition

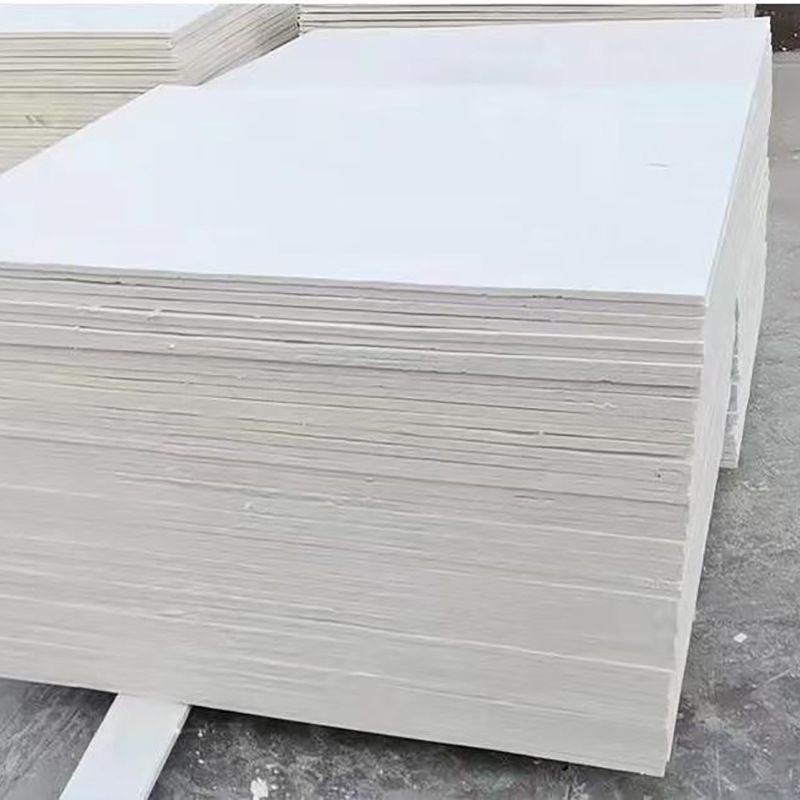

Calcium silicate board, also known as calcium silicate slab or panel, is a building material primarily composed of calcium oxide, silicon dioxide, and reinforcing fibers. These raw materials are mixed together, subjected to high - pressure and high - temperature autoclaving processes, and then cured to form a dense, rigid board. The reinforcing fibers, often made of cellulose or inorganic materials, enhance the board's strength and flexibility, making it suitable for various applications.

One of the key features of calcium silicate board is its inorganic nature, which contributes to its outstanding performance in different environments. Unlike organic - based materials, it does not degrade easily, resist pests, and has a long lifespan, making it a reliable option for both short - term and long - term projects.

Key Properties

Fire Resistance

Calcium silicate board is renowned for its excellent fire - resistant properties. It typically achieves a Class A1 fire - rating, meaning it is non - combustible and does not contribute to the spread of fire. In the event of a fire, the board can maintain its structural integrity for an extended period, providing a crucial barrier that helps protect buildings and their occupants. This makes it an ideal choice for fire - rated partitions, ceilings, and wall linings in commercial, residential, and industrial buildings.

Thermal Insulation

The board also offers good thermal insulation capabilities. Its low thermal conductivity helps to reduce heat transfer, which is beneficial for maintaining a comfortable indoor temperature. In buildings, calcium silicate board can be used in exterior walls and roofs to minimize heat loss in cold weather and heat gain in hot weather, contributing to energy savings and enhanced comfort. In industrial applications, it can insulate pipes and equipment, preventing heat from escaping and improving overall process efficiency.

Moisture and Chemical Resistance

Calcium silicate board is highly resistant to moisture, making it suitable for use in humid environments such as bathrooms, basements, and areas prone to water exposure. It does not absorb water, which helps prevent issues like swelling, warping, and mold growth. Additionally, the board can withstand exposure to a variety of chemicals, making it a reliable option for industrial settings where corrosive substances may be present.

Sound Absorption

Another notable property of calcium silicate board is its ability to absorb sound. The dense structure of the board effectively dampens sound waves, reducing noise transmission between different areas. This makes it an excellent choice for interior partitions, ceilings, and walls in offices, schools, hospitals, and other buildings where noise control is essential.

Durability and Strength

With its high - strength composition, calcium silicate board is durable and can withstand mechanical stress, impact, and wear. It can support heavy loads and is resistant to cracking and chipping, ensuring long - term performance and reducing the need for frequent replacements.

Applications

Construction Industry

In the construction sector, calcium silicate board has a wide range of applications. It is commonly used for interior partition walls, providing a stable and fire - resistant barrier between rooms. For exterior cladding, it offers protection against the elements while enhancing the building's aesthetic appeal. In roofing systems, the board can be used as a base layer or insulation material, improving thermal performance and weather resistance.

Industrial Applications

In industrial settings, calcium silicate board is used for insulating high - temperature equipment, such as boilers, furnaces, and pipelines. Its heat - resistant and chemical - resistant properties make it suitable for harsh industrial environments. It can also be used as a lining material for industrial ovens and kilns, protecting the underlying structure from extreme temperatures.

Interior Decoration

For interior decoration, calcium silicate board can be easily cut, drilled, and shaped to create custom designs. It can be painted, tiled, or veneered to match various aesthetic requirements, making it a popular choice for creating stylish and functional interior spaces.

Advantages Over Other Materials

Compared to traditional building materials like gypsum board or plywood,

calcium silicate board offers several distinct advantages. Its superior fire resistance, moisture resistance, and durability make it a more reliable option, especially in demanding environments. While gypsum board may be susceptible to water damage and has lower fire ratings, calcium silicate board stands up well to both moisture and fire, reducing the risk of structural damage and ensuring long - term safety.

In conclusion, calcium silicate board is a high - performance building and industrial material with a wide range of applications and benefits. Its unique combination of fire resistance, thermal insulation, moisture resistance, and durability makes it an invaluable asset in modern construction, industrial, and interior design projects. Whether you're looking to enhance fire safety, improve energy efficiency, or create aesthetically pleasing spaces, calcium silicate board provides a reliable and effective solution.