Rosewool has become a high-quality Chinese rock wool blanket manufacturer both domestically and globally. Its products, as a multifunctional, durable, and cost-effective solution, can effectively meet the strict requirements of modern industry.

What Is a Rock Wool Blanket?

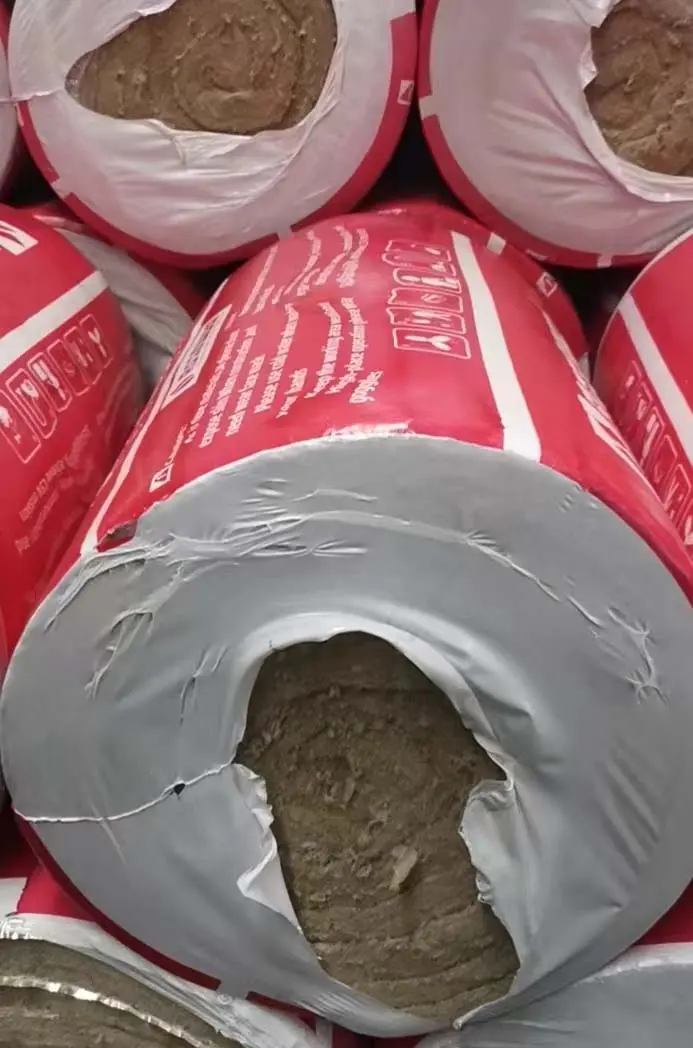

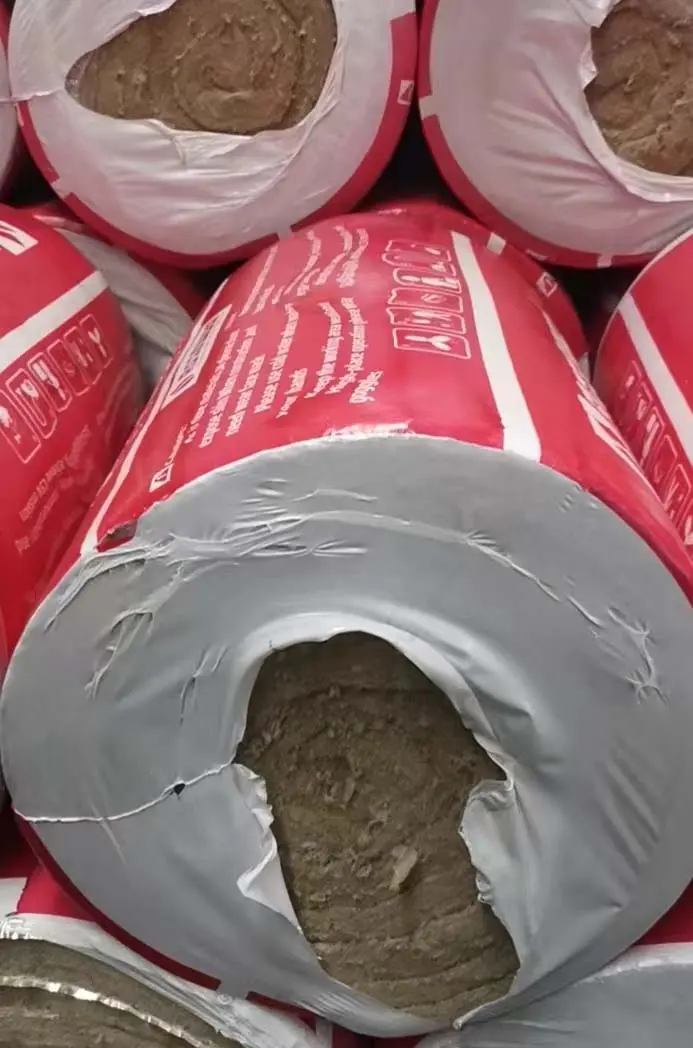

A rock wool blanket is a fibrous insulation material made from molten basalt rock, spun into fine fibers and bonded with a low-melting-point binder. It is valued for its exceptional heat resistance, thermal efficiency, and versatility, making it ideal for insulating pipes, ducts, boilers, and industrial equipment. Rosewool’s China-made rock wool blankets are engineered to exceed industry standards, combining raw material purity, advanced manufacturing, and tailored customization.

Key Advantages of Rosewool Rock Wool Blankets (China-Manufactured)

1. Superior Thermal Performance

Rosewool rock wool blankets deliver unmatched heat resistance, critical for China’s high-temperature industrial environments:

- Temperature Resistance: Withstands continuous use up to 700°C (standard grades) and 900°C (high-purity grades), making them suitable for boiler systems, kilns, and furnace linings.

- Low Thermal Conductivity: λ = 0.038–0.045 W/m·K at 400°C (vs. generic rock wool’s 0.04–0.05 W/m·K), reducing heat loss by 70–90% in insulated equipment.

2. Durability & Longevity

Rosewool’s blankets are built to last, even in abrasive or corrosive conditions:

- Fiber Density: 64–160 kg/m³ (adjustable based on application), balancing flexibility and structural integrity.

- Abrasion Resistance: Dense fiber matrix minimizes wear from high-velocity gases or particulate matter (common in cement kilns or steel mills).

- Service Life: 10–15 years in industrial settings (vs. 5–8 years for lower-quality blankets).

3. Fire Safety & Compliance

In China’s strict industrial safety landscape, Rosewool blankets meet critical fire standards:

- Non-Combustible Rating: Classified as A1 (non-flammable) per GB 8624-2012 (China’s national fire rating standard), ensuring they don’t burn or release toxic fumes.

- Certifications: ISO 9001:2015 (quality management), GB/T 16400 (rock wool product standards), and SGS-approved for safety and performance.

4. Customization for Diverse Applications

Rosewool tailors its rock wool blankets to China’s unique industrial needs:

- Sizes & Thicknesses: Available in rolls (1m x 6m, 2m x 6m) and custom dimensions (e.g., 3m x 10m for large ducts).

- Specialized Coatings: Aluminum foil-lined blankets reflect radiant heat (ideal for HVAC ducts), while low-chloride grades (<100 ppm Cl⁻) prevent corrosion in coastal or chemical plants.

Where Are Rosewool Rock Wool Blankets Used in China?

1. Power Generation

- Boiler Systems: Insulate high-pressure steam pipes, economizers, and superheaters in coal, gas, or biomass-fired plants. A 500MW power plant in Guangdong reduced annual fuel costs by 12% after switching to Rosewool blankets.

- HRSG (Heat Recovery Steam Generators): Line exhaust ducts to recover waste heat, boosting turbine efficiency by 5–8%.

2. Cement & Construction Materials

- Rotary Kilns: Protect kiln shells from thermal stress and corrosion, reducing maintenance costs by 30% for a 3000-ton/day cement plant in Hunan.

- Cooler Systems: Insulate clinker coolers to maintain safe surface temperatures (<50°C) and protect workers.

3. Steel & Metal Processing

- Annealing Ovens: Maintain consistent temperatures in heat-treatment chambers for steel and aluminum, ensuring material integrity.

- Foundries: Line casting molds or ladles to retain molten metal temperatures and reduce energy use.

4. Chemical & Petrochemical

- Reactor Vessels: Insulate lines carrying corrosive fluids (e.g., sulfuric acid, ammonia) while preventing CUI (Corrosion Under Insulation).

- Pipelines: Protect high-pressure pipes transporting hot crude oil (150–300°C) or natural gas in refineries.

Why Choose Rosewool for China Rock Wool Blankets?

1. Local Expertise, Global Standards

Rosewool combines China’s deep industrial knowledge with international manufacturing precision. Its state-of-the-art facilities in Jiangsu and Shandong provinces use automated fiber-spinning lines and strict quality control to ensure consistency.

2. Cost Efficiency Without Compromise

As a domestic manufacturer, Rosewool leverages economies of scale to offer 20–40% lower prices than European or North American suppliers—without sacrificing quality. This makes premium insulation accessible to SMEs and large enterprises alike.

3. End-to-End Support

Rosewool provides:

- Free Samples: Test thermal performance, thickness, and handling before bulk orders.

- Technical Assistance: Dedicated engineers help with insulation design, installation, and troubleshooting.

- Logistics Optimization: Sea/air freight options and customs clearance support for nationwide delivery.

4. Sustainability Commitment

Rosewool’s rock wool blankets are made from 70–80% recycled content (basalt rock from industrial byproducts) and are fully recyclable. This aligns with China’s “Dual Carbon” goals (carbon peak by 2030, carbon neutrality by 2060), reducing industrial carbon footprints.

FAQ: Common Questions About Rosewool Rock Wool Blankets

Q1: Are Rosewool rock wool blankets suitable for wet environments?

A: Yes—low-chloride grades (<100 ppm Cl⁻) resist corrosion from moisture and alkalis, making them ideal for cement coolers or coastal steel plants.

Q2: How long does installation take?

A: Pre-cut blankets reduce on-site labor by 40%. A 100m² area can be insulated in 2–3 hours with basic tools (e.g., utility knives, foil tape).

Q3: What’s the difference between Rockwool and Rosewool?

A: “Rockwool” is a generic term for basalt-based insulation. Rosewool is a trusted Chinese brand known for premium quality, customization, and compliance with China’s strict industrial standards.

Q4: Do Rosewool blankets meet Chinese fire safety regulations?

A: Absolutely—certified to GB 8624-2012 (A1 non-combustible) and GB/T 16400 (rock wool product standards).

In China’s rapidly evolving industrial sector, Rosewool rock wool blankets have become synonymous with reliability, efficiency, and cost-effectiveness. Through advanced manufacturing techniques, customized solutions, and strict adherence to national standards, Rosewool enables industries ranging from power generation to cement production to reduce energy expenditures, improve safety performance, and achieve sustainability objectives.