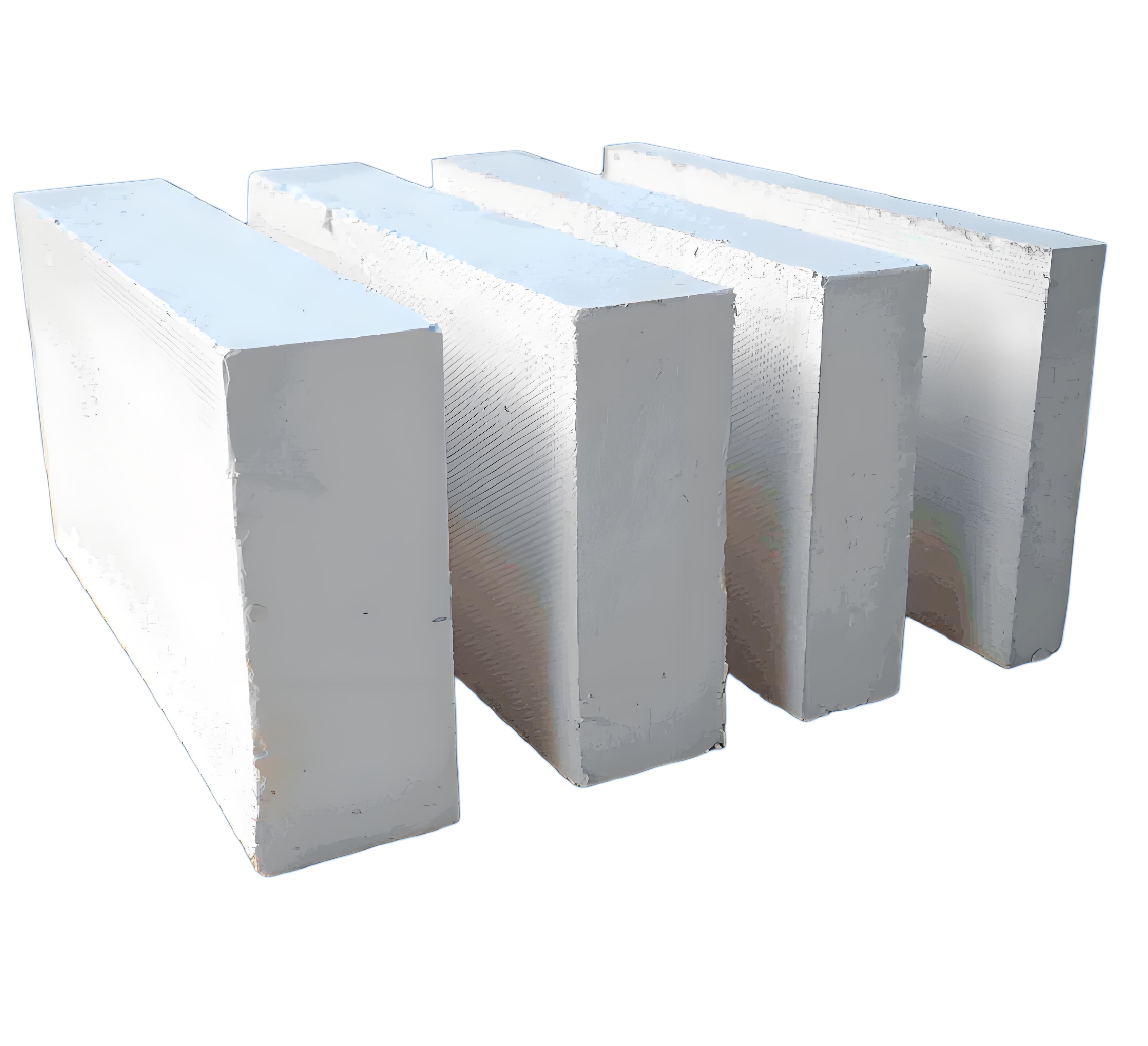

Ceramic fibre board (also called ceramic fiber board) is a rigid, high-performance insulation material engineered from alumina-silica ceramic fibers (typically 70–90% alumina [Al₂O₃] and 10–30% silica [SiO₂]). Unlike soft, flexible ceramic fiber blankets, boards are pressed or extruded into dense, flat sheets, making them ideal for structural applications where shape retention and mechanical strength are critical.

Key Manufacturing Steps:

- Fiber Production: Alumina and silica are melted at ~1800°C (3272°F) to form molten fibers, which are spun or blown into fine strands (diameter: 2–5 microns).

- Binding & Forming: Fibers are mixed with a low-melting-point binder (e.g., silica sol) and pressed into molds to create dense, uniform sheets.

- Curing: The boards are cured at high temperatures to remove binders and enhance structural integrity.

- Finishing: Some boards are reinforced with aluminum foil, mesh, or coatings for added durability or moisture resistance.

Key Properties That Define Ceramic Fibre Board

1. Extreme Temperature Resistance

- Continuous Use: Most standard boards withstand 800–1200°C (1472–2192°F) continuously. High-purity grades (≥96% Al₂O₃) handle up to 1400°C (2552°F).

- Short-Term Peaks: Survive short bursts of 1600°C (2912°F) (e.g., furnace startups or exhaust spikes).

2. Superior Thermal Insulation

- Low Thermal Conductivity: At 800°C, λ = 0.10–0.15 W/m·K (vs. fiberglass’ λ = 0.04–0.05 W/m·K at lower temps, but fiberglass degrades above 450°C).

- Energy Efficiency: Reduces heat loss by 70–90% in industrial systems, cutting fuel costs by 15–30% long-term.

3. Fire & Combustion Resistance

- Non-Combustible: Rated A1 (non-flammable) per EN 13501-1, meaning it won’t burn, melt, or release toxic fumes in flames—critical for fireproofing HVAC ducts, server rooms, or oil refineries.

4. Mechanical Strength & Durability

- Rigidity: Unlike soft blankets, boards hold their shape under pressure, making them ideal for lining furnaces, ducts, or machinery components.

- Impact Resistance: Withstands minor impacts (e.g., tool drops) better than fragile insulation materials.

5. Moisture & Chemical Resistance

- Low Moisture Absorption: Standard boards absorb <1% water by weight (vs. fiberglass’ 5–10% absorption).

- Corrosion Resistance: Resists attack from acids (e.g., sulfuric acid) and alkalis (e.g., sodium hydroxide) when using low-chloride grades (<100 ppm Cl⁻).

Where Is Ceramic Fibre Board Used?

1. Industrial Furnaces & Kilns

- Furnace Walls/Ceilings: Insulate high-temp chambers (e.g., aluminum melting furnaces, ceramic kilns) to maintain uniform temperatures and reduce energy waste.

- Hearth Liners: Protect refractory bases from thermal shock and erosion.

2. Power Generation

- Boiler Systems: Line steam pipes, economizers, or superheaters to minimize heat loss in coal, gas, or biomass-fired plants.

- HRSG (Heat Recovery Steam Generators): Insulate exhaust ducts to recover waste heat and boost turbine efficiency.

3. Oil & Gas & Chemical Processing

- Pipeline Insulation: Wrap high-pressure pipes carrying hot crude oil (150–300°C) or natural gas in offshore rigs.

- Reactor Vessels: Insulate lines carrying corrosive fluids (e.g., ammonia, sulfuric acid) while preventing CUI (Corrosion Under Insulation).

4. Metal Processing

- Annealing Ovens: Insulate chambers for heat-treating metals (e.g., steel, aluminum) to ensure consistent material properties.

- Foundries: Line casting molds or ladles to retain molten metal temperatures and reduce energy use.

5. Renewable Energy

- Biomass Boilers: Insulate high-temp exhaust systems in bioenergy plants to improve combustion efficiency.

- Concentrated Solar Power (CSP): Line receiver tubes to retain thermal energy, boosting electricity output.

Ceramic Fibre Board vs. Traditional Insulation Materials

| Property |

Ceramic Fibre Board |

Fiberglass Board |

Rock Wool Board |

| Max Temp Resistance |

800–1400°C |

450–600°C |

600–800°C |

| Thermal Conductivity @800°C |

0.10–0.15 W/m·K |

0.04–0.05 W/m·K (degrades) |

0.04–0.045 W/m·K (moisture-sensitive) |

| Fire Rating |

A1 (non-combustible) |

B1 (limited combustibility) |

A1 (non-combustible) |

| Moisture Resistance |

High (low absorption) |

Low (absorbs 5–10% water) |

Moderate (absorbs 1–3% water) |

| Mechanical Strength |

Rigid, impact-resistant |

Fragile, prone to crushing |

Dense, but heavy |

Choosing the Right Ceramic Fibre Board

1. Temperature Grade

- Standard Grades: For temps up to 800–1000°C (e.g., steam pipes, HVAC ducts).

- High-Purity Grades: For temps >1000°C (e.g., industrial furnaces, boiler exhausts).

2. Thickness

- Thinner boards (20–30mm) for moderate temps (≤800°C); thicker boards (50–100mm) for higher temps (>1000°C).

3. Specialized Coatings

- Aluminum Foil Lined: Enhances moisture resistance and reflects radiant heat (ideal for ducts).

- Low-Chloride Coatings: Prevents corrosion in coastal or chemical environments.

FAQ: Common Questions About Ceramic Fibre Board

Q1: Is ceramic fibre board the same as ceramic fiber blanket?

A: No—blankets are soft, flexible sheets for wrapping pipes, while boards are rigid and used for structural insulation (e.g., furnace walls).

Q2: Can ceramic fibre board handle thermal cycling (hot/cold fluctuations)?

A: Yes—its low thermal expansion and crack-resistant structure make it ideal for cyclic high-heat environments (e.g., gas turbines, industrial ovens).

Q3: How do I cut or install ceramic fibre board?

A: Use a utility knife with a diamond blade for clean cuts. Seal edges with high-temp silicone caulk or aluminum foil tape to prevent heat leakage.

Q4: Is ceramic fibre board eco-friendly?

A: Yes—it’s made from abundant minerals (alumina/silica), contains up to 80% recycled content, and is fully recyclable.

Q5: How long does ceramic fibre board last?

A: With proper installation, 10–15 years in industrial settings (vs. 5–8 years for fiberglass).

Whether you’re insulating a power plant boiler or a metal foundry oven, ceramic fibre board delivers unmatched performance where other materials simply can’t keep up.